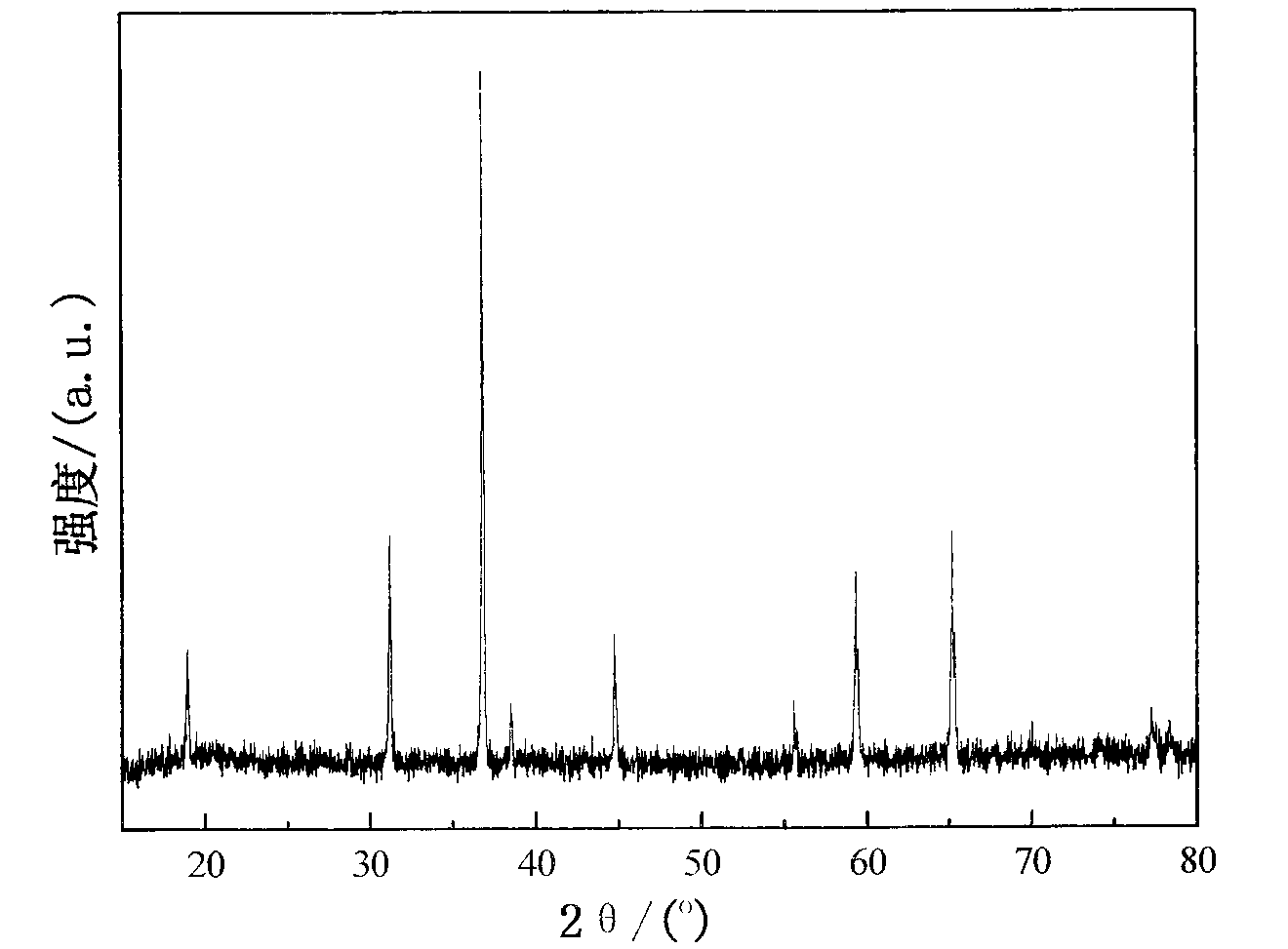

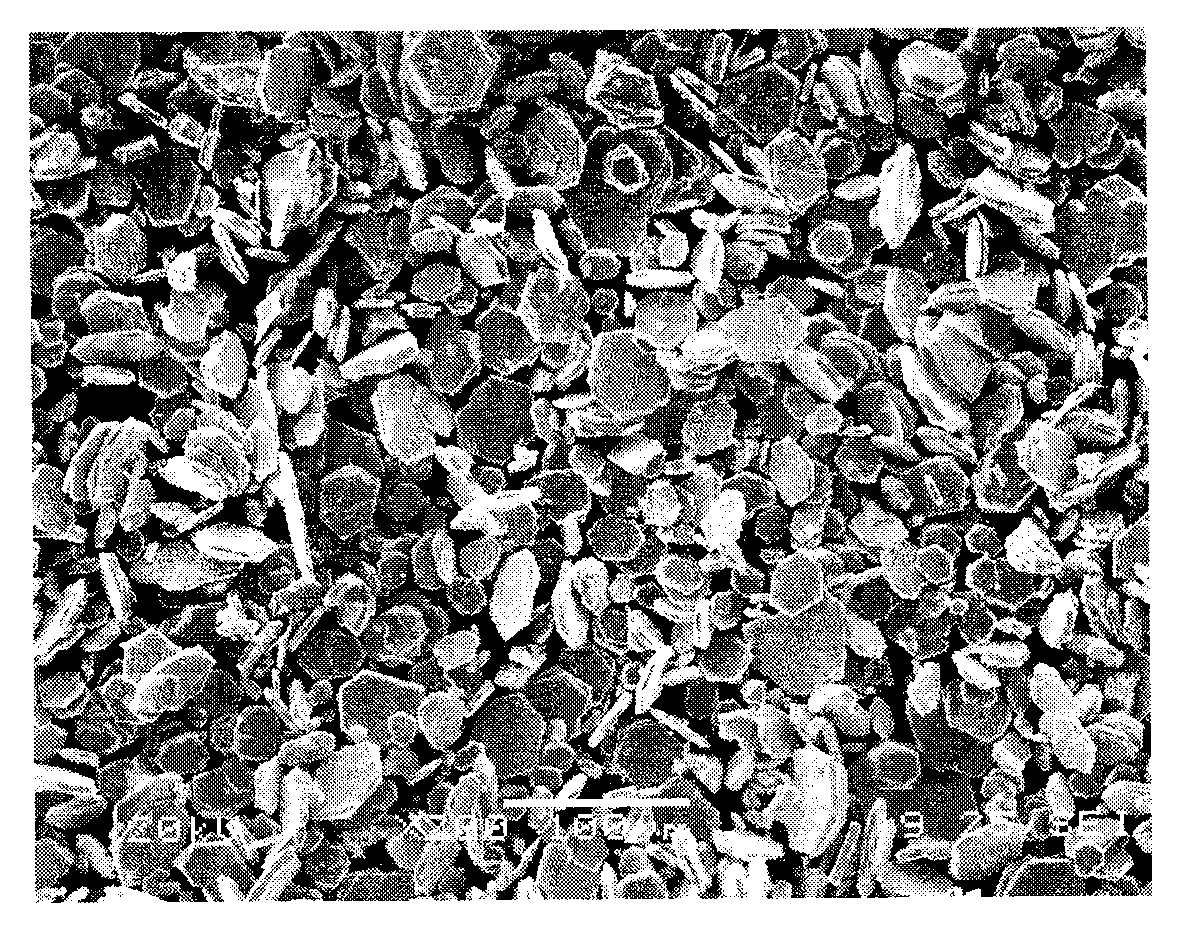

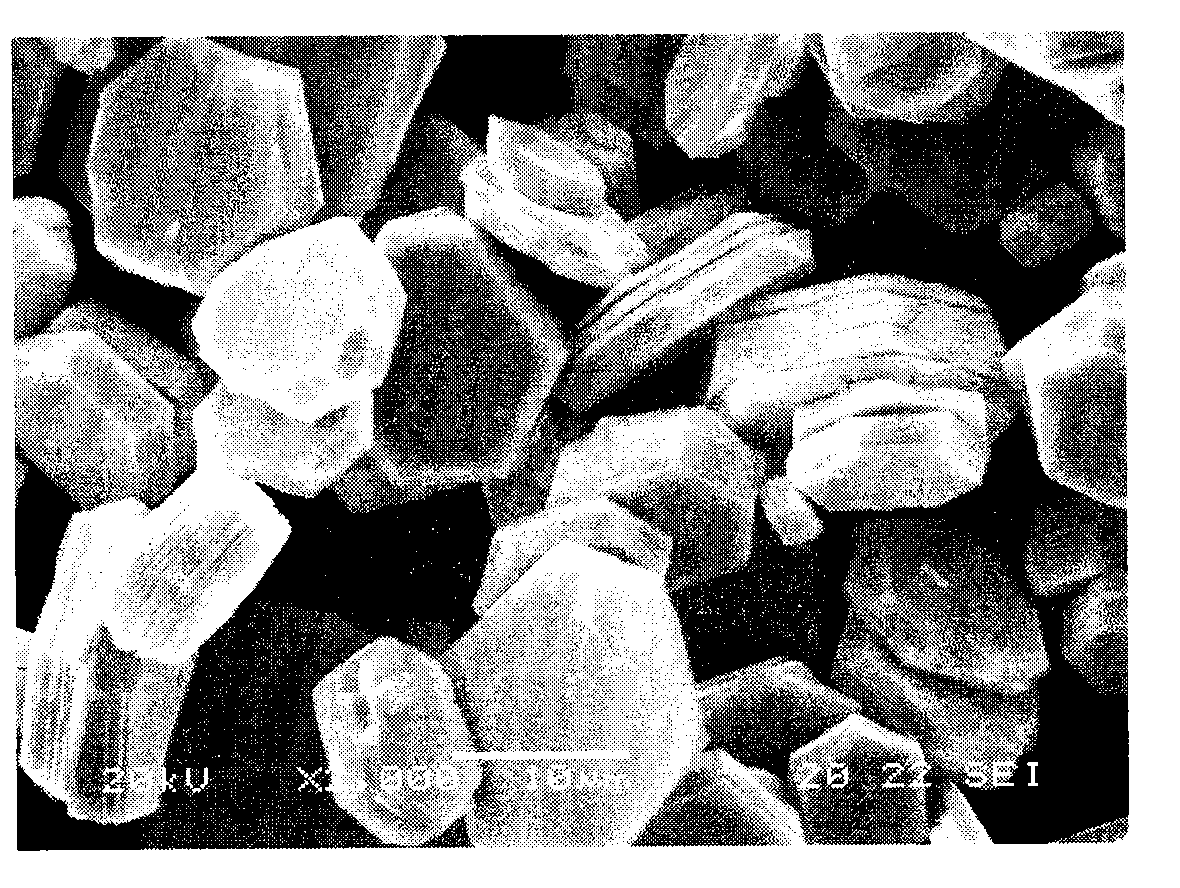

Method for preparing hexagonal plate cobaltosic oxide

A technology of tricobalt tetroxide and hexagonal flakes, applied in cobalt oxide/cobalt hydroxide and other directions, can solve the problems of long preparation time, cracks on the surface of product hexagonal flakes, etc., achieve uniform particle size, reduce energy consumption and preparation cost, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 The preparation method of hexagonal sheet cobalt tetroxide, comprising the following steps:

[0025] (1) Mixing: the cobalt raw material - CoCl 2 ·6H 2 O, strong alkali saturated solution - sodium hydroxide saturated solution and flux - H 3 BO 3 The sintered material was obtained by stirring at a molar ratio of 1:3:1 for 20 minutes to make it fully mixed, and then placed in an oven for 24 hours at a temperature of 80°C.

[0026] (2) Roasting: After pulverizing the sintered material to 40-80 mesh, transfer it to a roasting crucible, send it to a roasting furnace to heat up at a rate of 5-10°C / min, roast at 750°C for 3 hours, and then cool it naturally, A sintered product was obtained.

[0027] (3) Immersion: the sintered product with the crucible was soaked in 0.1M hydrochloric acid for 1 hour, washed and filtered to obtain a wet product of cobalt tetroxide hexagonal sheet.

[0028] (4) Drying: put the wet product of hexagonal tricobalt tetroxide into a...

Embodiment 2

[0029] Embodiment 2 The preparation method of hexagonal sheet cobalt tetroxide, comprising the following steps:

[0030] (1) Mixing: the cobalt raw material - CoCl 2 ·6H 2 O, strong alkali saturated solution - potassium hydroxide saturated solution and flux - KCl is stirred at a molar ratio of 1:4:5 for 20min to make it fully mixed, and then put into an oven and dried at 80 ° C for 24h After that, a sintered material is obtained.

[0031] (2) Roasting: After pulverizing the sintered material to 40-80 mesh, transfer it to a roasting crucible, send it into a roasting furnace to heat up at a rate of 5-10°C / min, roast at 900°C for 6 hours, and cool it naturally. A sintered product was obtained.

[0032] (3) Immersion: The sintered product with the crucible was soaked in 1M hydrochloric acid for 0.5h, washed and filtered to obtain a wet product of cobalt tetroxide hexagonal sheet.

[0033] (4) Drying: Put the wet product of hexagonal tricobalt tetroxide into an oven, adjust the...

Embodiment 3

[0034] Embodiment 3 The preparation method of hexagonal sheet cobalt tetroxide, comprising the following steps:

[0035] (1) Mixing: the cobalt raw material - CoSO 4 ·7H 2 O, strong alkali saturated solution - sodium hydroxide saturated solution and flux - Na 2 B 4 O 7 ·10H 2 O was stirred at a molar ratio of 1:6:2 for 20 minutes to make it fully mixed, and then placed in an oven for 48 hours at a temperature of 80°C to obtain a sintered material.

[0036](2) Roasting: After pulverizing the sintered material to 40-80 mesh, transfer it to a roasting crucible, send it to a roasting furnace to heat up at a rate of 5-10°C / min, and calcinate at 800°C for 0.5h, then cool it naturally. , to obtain a sintered product.

[0037] (3) leaching: the sintered product with the crucible was soaked in 2M hydrochloric acid for 3 hours, washed and filtered to obtain a wet product of cobalt tetroxide hexagonal sheet.

[0038] (4) Drying: put the wet product of hexagonal tricobalt tetroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com