Magnesium-doped positive electrode material for magnesium ion battery and preparation method thereof

A technology for magnesium ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor compatibility between materials and electrolytes, slow dynamic insertion of magnesium, and difficulty in moving embedded materials, etc., to achieve scale Chemical industry production, stable crystal structure, improved electrical conductivity and electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a magnesium-site doped magnesium ion battery cathode material includes the following steps:

[0033] Accurately weigh 0.98mol of Mg(OH) 2 , 0.02mol of Ca(OH) 2 , 1.0mol of Ni(OH) 2 , Add an appropriate amount of deionized water, ball mill and mix uniformly, take it out and dry at 120°C, pre-burn at 400°C for 2 hours, and crush into powder. Weigh 1.0 mol of tetraethylorthosilicate, add the solid powder, tetraethylorthosilicate and 5.75g of citric acid into a stainless steel tank lined with polytetrafluoroethylene, mix thoroughly in anhydrous ethanol solvent, and in a sealed state Incubate at 210°C for 4 days to obtain a gel. After drying the gel, it was mixed with 32 grams of glucose and ball milled, and sintered in an inert atmosphere at 1050°C for 6 hours to obtain a carbon-coated magnesium ion battery cathode material Mg 0.98 Ca 0.02 NiSiO 4 .

[0034] Performance Testing:

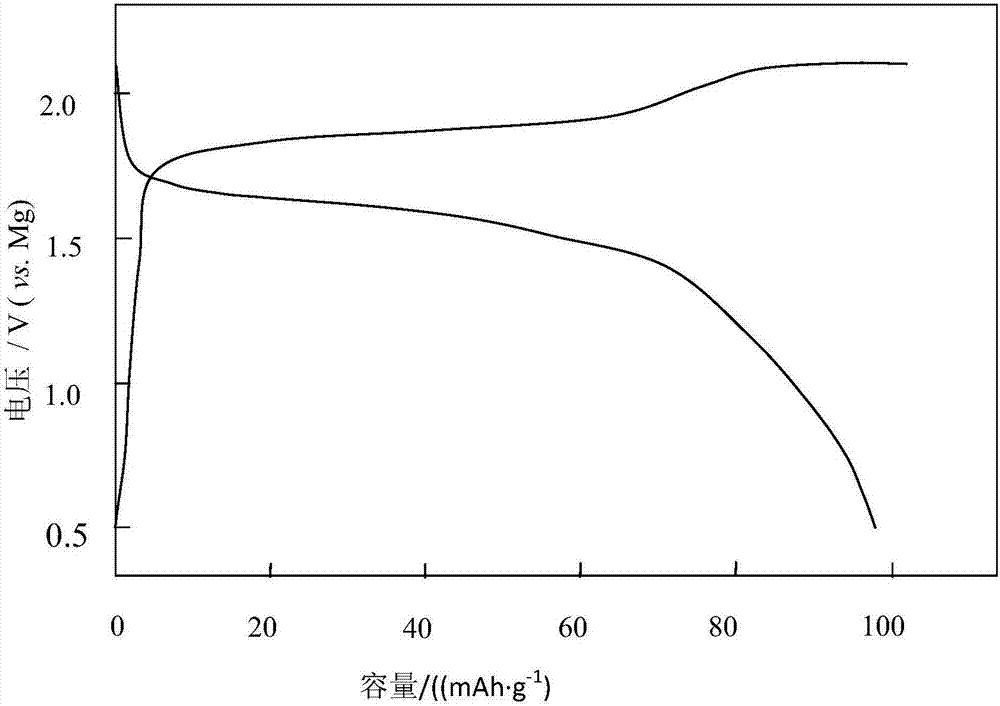

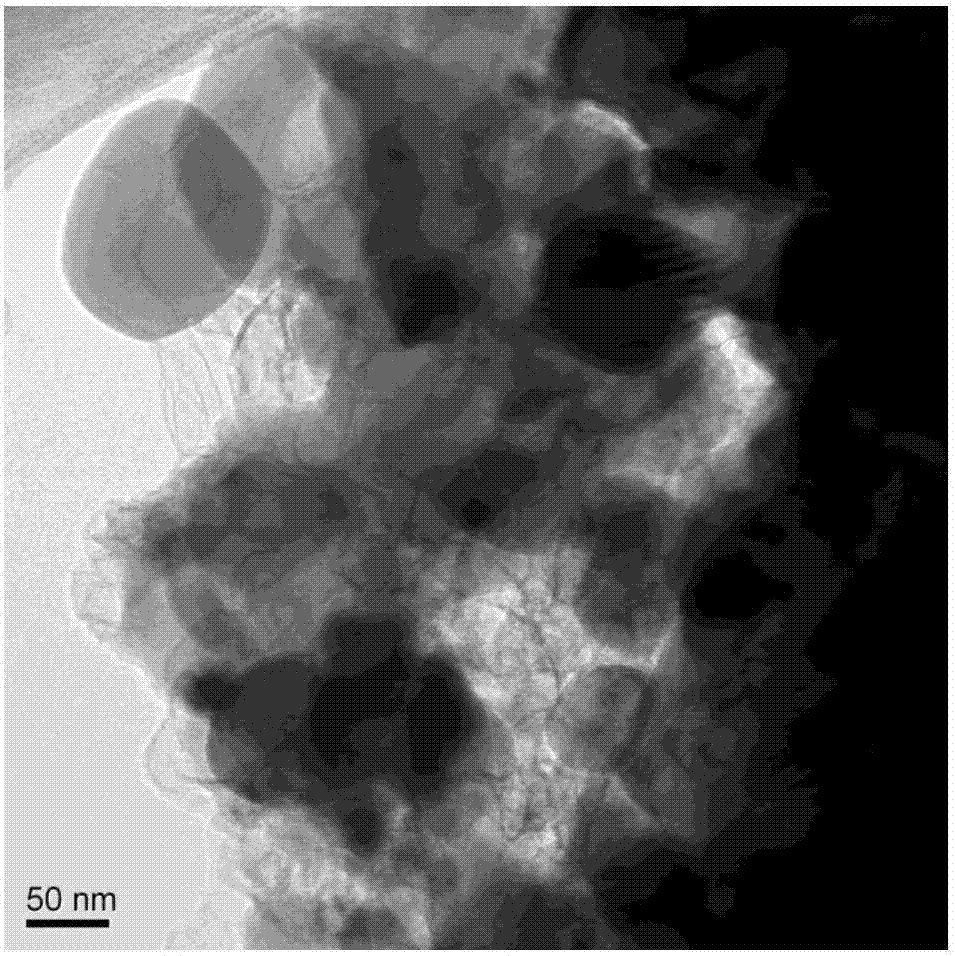

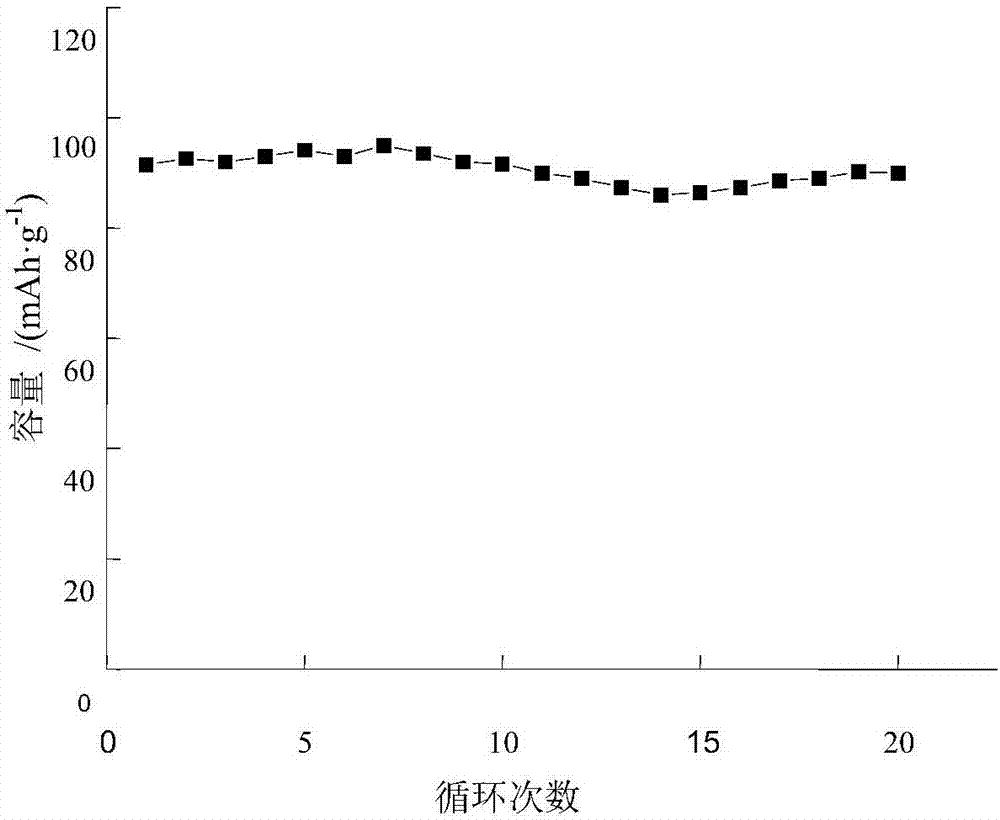

[0035] The synthesized magnesium ion battery cathode material Mg 0.98 Ca 0.0...

Embodiment 2

[0039] Accurately weigh 0.97mol of magnesium acetate, 0.03mol of strontium oxalate, 1.0mol of nickel oxalate, add an appropriate amount of deionized water, ball mill and mix uniformly, take it out, dry at 120°C, pre-fire at 350°C for 4 hours, and crush into powder . Weigh 1.0 mol of tetraethylorthosilicate, add the solid powder, tetraethylorthosilicate and 9.2g of citric acid to a stainless steel tank lined with polytetrafluoroethylene, mix well in anhydrous ethanol solvent, and in a sealed state Incubate at 260°C for 2 days to obtain a gel. After drying the gel, it was mixed with 45 grams of glucose and ball milled, and sintered in an inert atmosphere at 1100°C for 4 hours to obtain a carbon-coated magnesium ion battery cathode material Mg 0.97 Sr 0.03 NiSiO 4 .

[0040] Performance Testing:

[0041] The synthesized magnesium ion battery cathode material Mg 0.97 Sr 0.03 NiSiO 4 Mix uniformly with acetylene black and polytetrafluoroethylene at a mass ratio of about 75:15:10. Use ...

Embodiment 3

[0043] Accurately weigh 0.99 mol of magnesium oxalate, 0.01 mol of barium hydroxide, and 1.0 mol of nickel acetate, add an appropriate amount of deionized water, ball mill and mix uniformly, take it out, dry at 120°C, pre-burn at 380°C for 3 hours, and crush into powder. Weigh 1.0 mol of tetraethylorthosilicate, add the solid powder, tetraethylorthosilicate and 10.5g of citric acid into a stainless steel tank lined with polytetrafluoroethylene, mix thoroughly in anhydrous ethanol solvent, and in a sealed state Incubate at 300°C for 1 day to obtain a gel. After drying the gel, it was mixed with 25 grams of polyethylene glycol and ball milled, and sintered in an inert atmosphere at 950°C for 6 hours to obtain a carbon-coated magnesium ion battery cathode material Mg 0.99 Ba 0.01 NiSiO 4 .

[0044] The synthesized magnesium ion battery cathode material Mg 0.99 Ba 0.01 NiSiO 4 Mix uniformly with acetylene black and polytetrafluoroethylene at a mass ratio of about 75:15:10. Use a fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com