A kind of cathode material of magnesium ion battery and preparation method thereof

A technology for magnesium ion batteries and positive electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low electronic conductivity and poor material discharge performance at high currents, and achieves simple operation, easy control, and realization of the preparation process. The effect of large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Accurately weigh 0.098molMgO, 0.002molSr(CH 3 COO) 2 , 0.010mol ZnO, 0.090mol FeC 2 o 4 2H 2 O and 0.1mol Si(CH 3 CH 2 O) 4 , put it into the agate tank of planetary ball mill after mixing evenly, add absolute ethanol as the mixing medium, fully ball mill with agate balls for 4 hours, dry at 120°C, put the powder in a tube furnace at high temperature Under the protection of pure nitrogen, heat up to 400°C at a heating rate of 5°C / min, hold for 1 hour, continue to heat up to 1000°C, and hold for 6 hours to obtain the positive electrode material Mg for magnesium ion batteries. 0.98 Sr 0.02 Zn 0.1 Fe 0.9 SiO 4 .

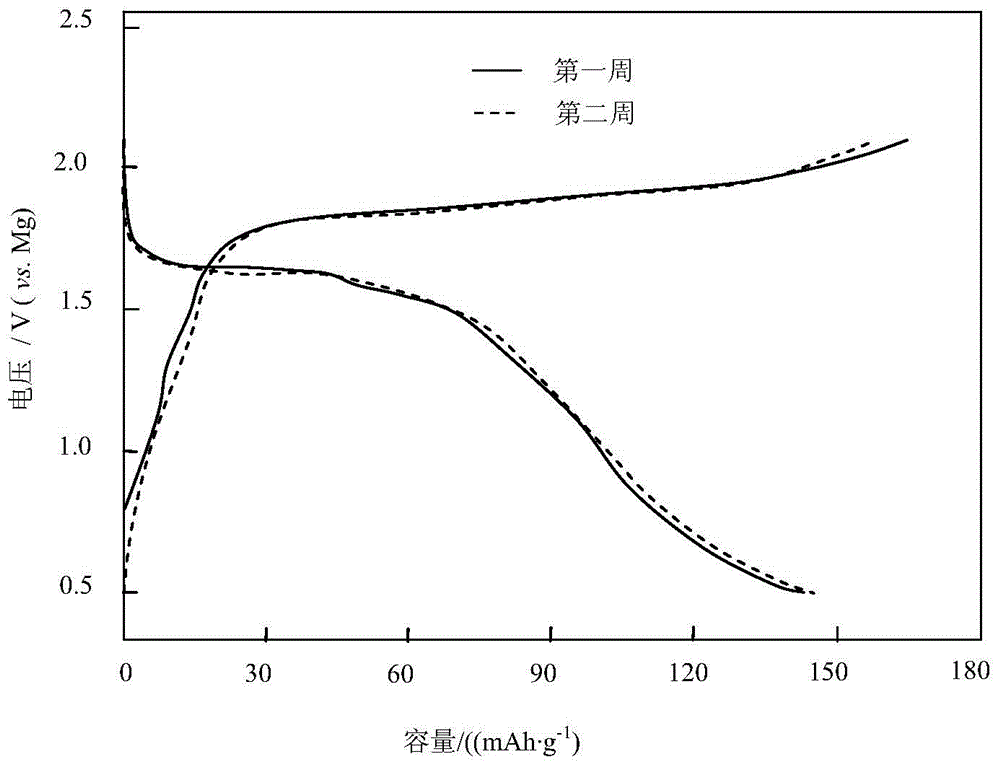

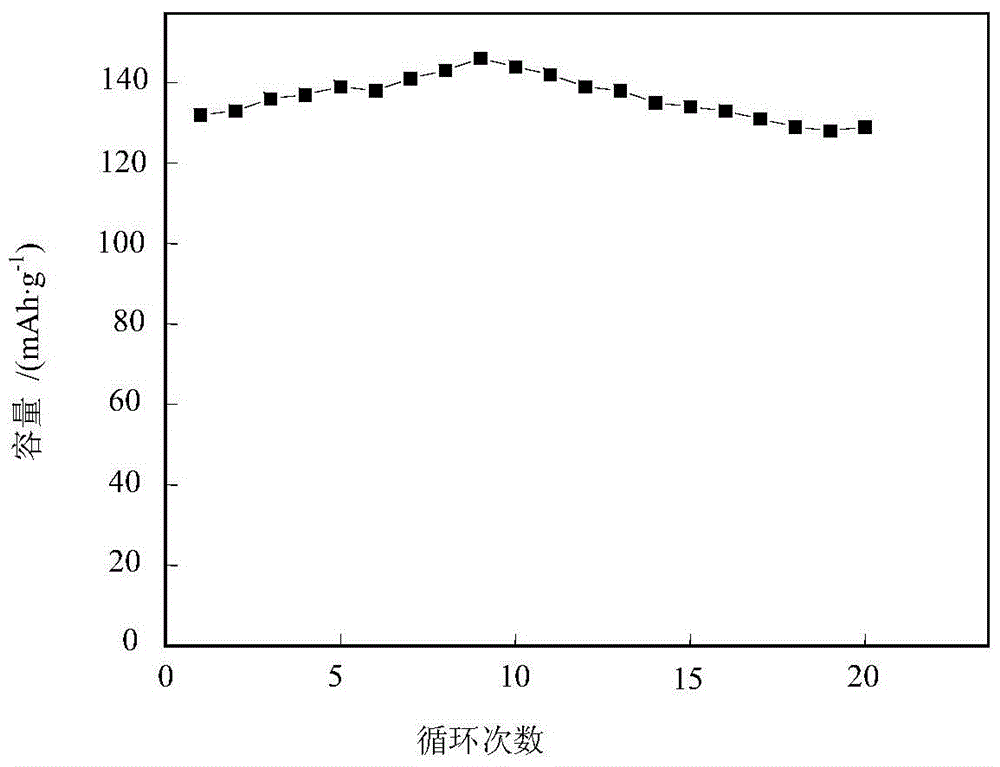

[0026] The synthesized magnesium ion battery cathode material Mg 0.98 Sr 0.02 Zn 0.1 Fe 0.9 SiO 4 Mix evenly with acetylene black and polytetrafluoroethylene at a mass ratio of about 75:15:10, press it into a film with a thickness of about 1mm with a film laminator, and dry it fully in an oven at 100°C. The intercepted surface area is 1cm 2 Circu...

Embodiment 2

[0028] Accurately weigh 0.096molMg(OH) 2 , 0.004molSrO, 0.013mol ZnO, 0.087molFeO and 0.1molSi(CH 3 CH 2 O) 4 , mix evenly and put it into the agate tank of the planetary ball mill, add absolute ethanol as the mixing medium, use agate balls to fully mill for 3 hours, dry at 120°C, put the powder in a tube furnace at high temperature Under the protection of pure nitrogen, heat up to 350°C at a heating rate of 4°C / min, hold for 2 hours, continue to heat up to 1100°C, and hold for 4 hours to obtain the positive electrode material Mg for magnesium ion batteries. 0.96 Sr 0.04 Zn 0.13 Fe 0.87 SiO 4 .

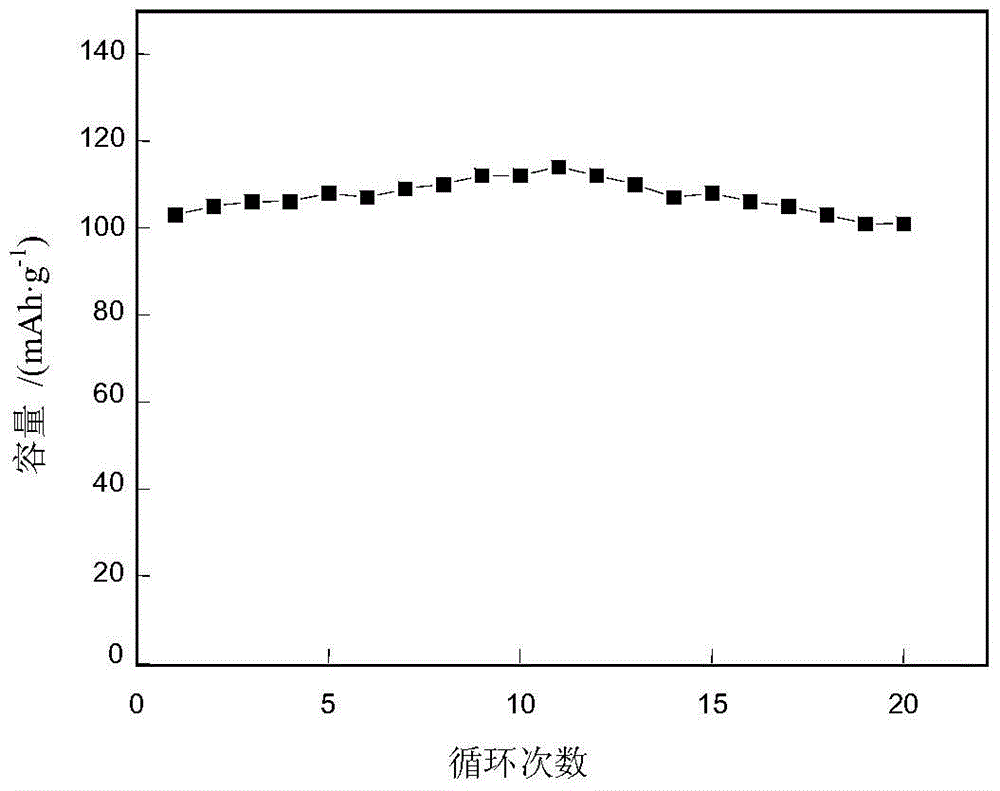

[0029] The synthesized magnesium ion battery cathode material Mg 0.96 Sr 0.04 Zn 0.13 Fe 0.87 SiO 4 Mix evenly with acetylene black and polytetrafluoroethylene at a mass ratio of about 75:15:10, press it into a film with a thickness of about 1mm with a film laminator, and dry it fully in an oven at 100°C. The intercepted surface area is 1cm 2 Circular membranes, pressed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com