A kind of composite oxide glass-ceramic, insulating medium paste and preparation method and application thereof

A composite oxide and glass-ceramics technology, applied in the direction of metal oxides, insulators, insulators, etc., can solve the problems of limited dielectric strength, short circuit, etc., and achieve the effects of improved compactness, simple preparation process, and large coordination capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

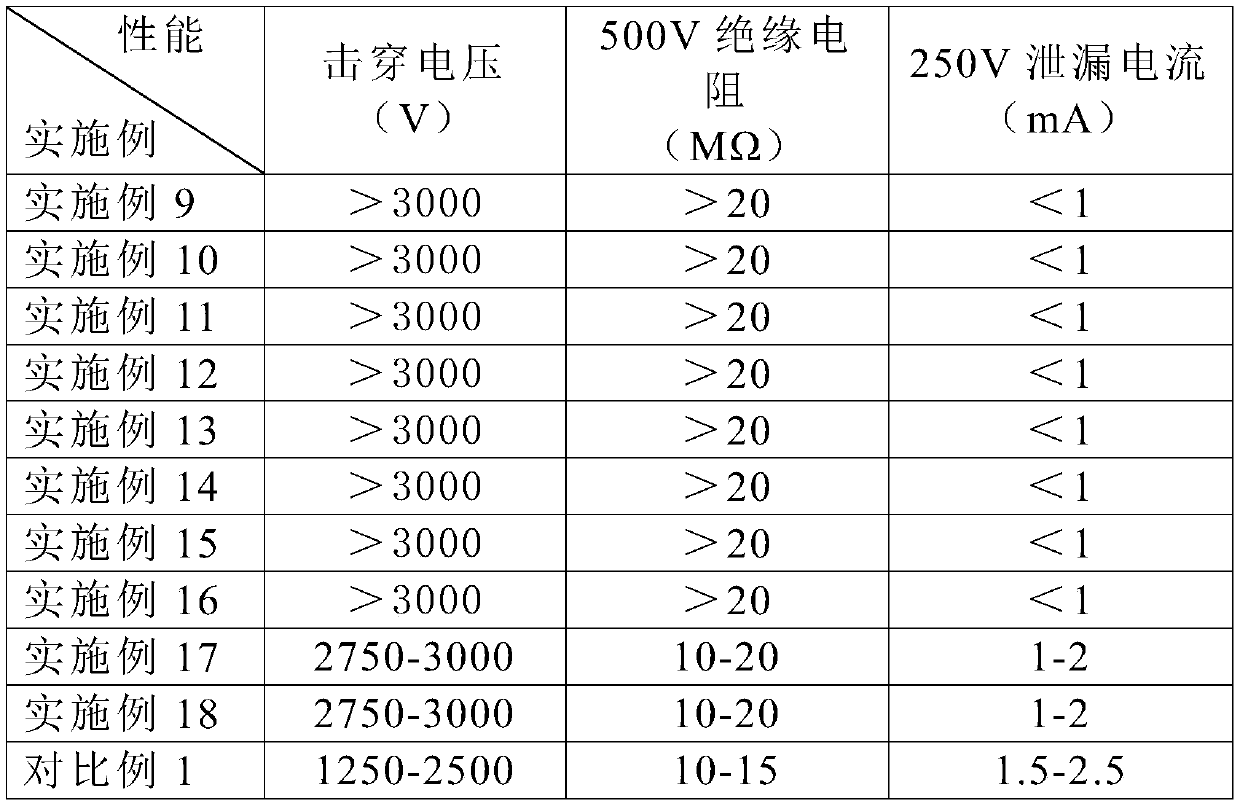

Examples

Embodiment 1

[0025] A composite oxide glass-ceramic, SiO 2 -B 2 o 3 -Cs 2 O-P 2 o 5 -MnO 2 -Co 2 o 3 -Ta 2 o 5 -CeO 2 -Er 2 o 3 Composite oxide glass-ceramics, the mass percentage of each component is SiO 2 : 32.5%, B 2 o 3 : 20%, Cs 2 O: 8%, P 2 o 5 : 24%, MnO 2 : 3.5%, Co 2 o 3 : 1%, Ta 2 o 5 : 6%, CeO 2 : 2.5%, Er 2 o 3 : 2.5%.

Embodiment 2

[0027] The difference from Example 1 is that the mass percent of each component of the composite oxide glass-ceramics in this example is SiO 2 : 25%, B 2 o 3 : 11%, Cs 2 O: 12%, P 2 o 5 : 40%, MnO 2 : 3%, Co 2 o 3 : 1.5%, Ta 2 o 5 : 4%, CeO 2 : 2%, Er 2 o 3 : 1.5%.

Embodiment 3

[0029] The difference from Example 1 is that the mass percent of each component of the composite oxide glass-ceramics in this example is SiO 2 : 39%, B 2 o 3 : 20%, Cs 2 O: 4%, P 2 o 5 : 20%, MnO 2 : 5%, Co 2 o 3 : 1.5%, Ta 2 o 5 : 7%, CeO 2 : 2.5%, Er 2 o 3 :1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown voltage | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com