Preparation method and application of flocculant for treating urban sewage

A technology of urban sewage and flocculant, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of low degree of automation, limited molecular weight, loose structure, etc., to achieve good economic and social benefits, fast sedimentation rate, stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take the prepared water glass with a modulus of 2.8, dilute with water to adjust the content to a silica content of 2wt%, and pass the solution through an exchange column filled with American Amberlite IR-120 cation exchange resin to obtain a sodium oxide content of 0.8wt% and a pH of 3.6 dilute silica gel. Under stirring with a Reynolds number of 7500, the mixture obtained above was added to a 10 wt% aluminum sulfate solution having a molar ratio of 5 times the silicate radical, while cooling to keep the temperature of the mixture below 40°C. Then adjust the pH of the stirred mixture to 5 with 5 wt% sodium aluminate solution to produce a clear solution, which is the prepared liquid inorganic composite flocculant, which can be put into use.

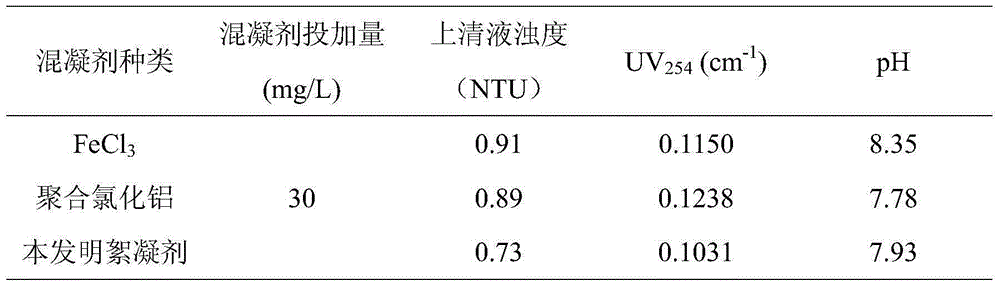

[0026] Raw water is selected from native lake water with a turbidity of 14.3NTU, a pH of 8.4, and a water temperature of 14°C. The proportion of adding sewage is 0.05wt%. The operating conditions of the beaker test of the six-way...

Embodiment 2

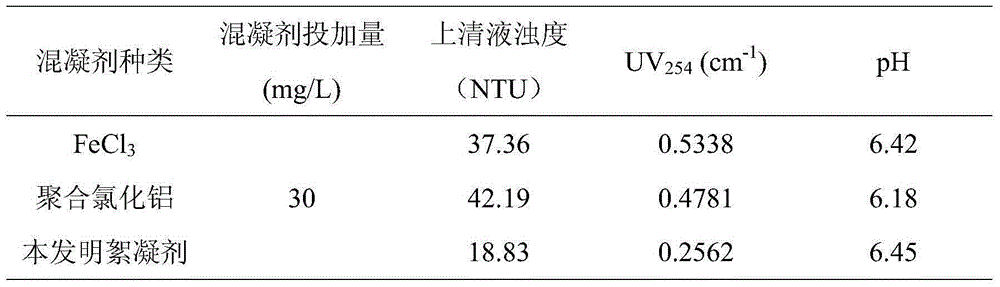

[0031] Get the solid water glass with a modulus of 3.5 and put it into an autoclave to feed water vapor and keep 3 atmospheric pressure to carry out the pressure steaming reaction to generate liquid water glass. Dilute with water to adjust the content to a silica content of 5 wt%, and pass the solution through an exchange column filled with Amberlite IR-120 cation exchange resin from the United States to obtain a silicic acid colloid solution with a sodium oxide content of 0.5 wt% and a pH of 3.2. Under stirring with a Reynolds number of 7000, the mixture obtained above was added to a 15 wt% aluminum chloride solution whose molar ratio to silicate was 10 times, while cooling to keep the temperature of the mixture below 40°C. Then adjust the pH of the stirred mixture to 5.2 with 7wt% sodium aluminate solution, and dry it in a Shunyi SP-1500 small spray dryer to produce a white solid powder, which is the prepared solid inorganic composite flocculation agent, and the obtained whi...

Embodiment 3

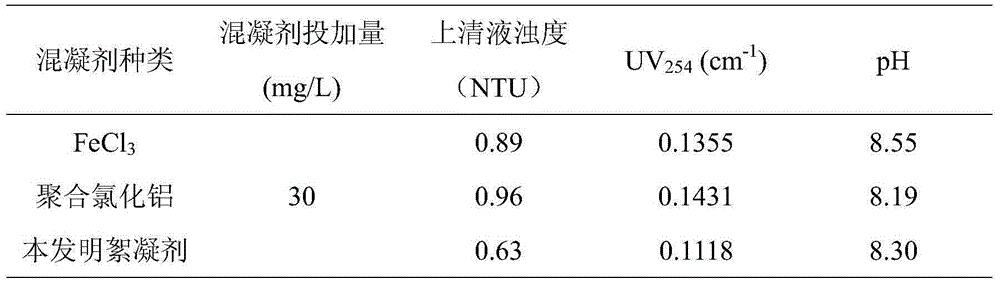

[0036]Get the solid water glass with a modulus of 3.5 and put it into the autoclave to feed water vapor and keep 6 atmospheres to carry out the pressure steaming reaction to generate liquid water glass. Dilute with water to adjust the content to a silica content of 10wt%, and pass the solution through an exchange column filled with NKC-9 macroporous strong acidic cation exchange resin to obtain a silica gel thin solution with a sodium oxide content of 0.32wt% and a pH of 2.9. With stirring at a Reynolds number of 6500, the mixture obtained above was added to a 20 wt% aluminum nitrate solution whose molar ratio to silicate was 30 times, while cooling to keep the temperature of the mixture below 40°C. Then adjust the pH of the stirred mixture to 6 with a 10wt% concentration of sodium aluminate solution, and dry it in a Shunyi SP-1500 small spray dryer to produce a white solid powder, which is the prepared solid inorganic composite flocculation agent, and the obtained white powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com