Method for producing polymeric aluminium ferric sulfate solution from industrial waste sulfuric acid generated during purification of acetylene gas and red mud

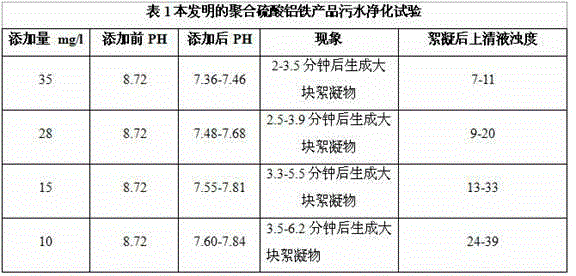

A technology of polymerizing aluminum ferric sulfate and waste sulfuric acid, which is applied in ferric sulfate, flocculation/sedimentation water/sewage treatment, etc., to achieve the effect of simple process, less metal residue and fast settling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The waste sulfuric acid produced by purifying acetylene gas in the production process of 1,4-butanediol is a stable dark brown liquid, which is composed of 80% sulfuric acid, 11% water, 9% organic matter and dust by weight percentage, and the dry red mud is brown solid According to the X-ray fluorescence spectrometry analysis in the industry standard YS / T 575.23-2009 of the People's Republic of China, 21% of silicon dioxide, 24% of aluminum oxide, 17% of iron oxide, 16% of calcium oxide, 6% of sodium oxide, and 16% of other %, water and red mud are mixed and pulped, the water content of the pulped red mud is 78%, the pulped red mud and waste sulfuric acid are uniformly mixed according to the weight ratio of 4:1, stirred and mixed for 2.5 hours, and the reacted mixture is obtained, and then allowed to stand Leach for 10 hours to obtain the leachate, filter to obtain the filtrate, mix diisooctyl phosphate with the filtrate at a volume ratio of 1:12, stir, leave to stand an...

Embodiment 2

[0026] The waste sulfuric acid produced by purifying acetylene gas in the production process of 1,4-butanediol is a stable dark brown liquid, which is composed of the following weight percentages: 85% sulfuric acid, 8% water, 7% organic matter and dust, and the alumina production line settles The thin red mud at the outlet of the tank has a water content of 70%. After drying to constant weight at 105-110°C, it is analyzed by X-ray fluorescence spectrometry in the industry standard YS / T 575.23-2009 of the People's Republic of China. Among them, 22% of silicon dioxide and 22% of oxidized Aluminum 25%, iron oxide 15%, calcium oxide 16%, sodium oxide 6%, other 16%, water and thin red mud are mixed and pulped, the water content of pulped red mud is 80%, pulped red mud and waste sulfuric acid are based on weight Mix evenly at a ratio of 5:1, stir and mix for 2 hours to obtain the reacted mixture, then stand for leaching for 7 hours to obtain the leachate, filter to obtain the filtrat...

Embodiment 3

[0028]The waste sulfuric acid produced by purifying acetylene gas during the production of 1,4-butanediol is a stable dark brown liquid, which is composed of the following weight percentages: sulfuric acid 90%, water 6%, organic matter and dust 4%, dry red mud is Brown solid, analyzed according to X-ray fluorescence spectrometry in the industry standard YS / T 575.23-2009 of the People's Republic of China, including 21% silicon dioxide, 24% aluminum oxide, 17% iron oxide, 16% calcium oxide, and 6% sodium oxide. The other 16%, water and red mud are mixed and pulped, the water content of pulped red mud is 70%, and waste sulfuric acid is uniformly mixed with waste sulfuric acid at a weight ratio of 2:1, stirred and mixed for 4 hours, and the reacted mixture is obtained, and then leached by standing for 12 Hours, get the leaching solution, filter to obtain the filtrate, diisooctyl phosphate and the filtrate are mixed at a volume ratio of 1:10, stirred, left to stand and layered into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com