Preprocessing technology for black liquor in diffusion dialysis recycling pulp manufacture

A technology of diffusion dialysis and recovery of pulp, which is applied in the field of pulp manufacturing, can solve the problems of reducing COD value, achieve the effect of reducing COD value, improving recovery rate and recovery amount, and large flocs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

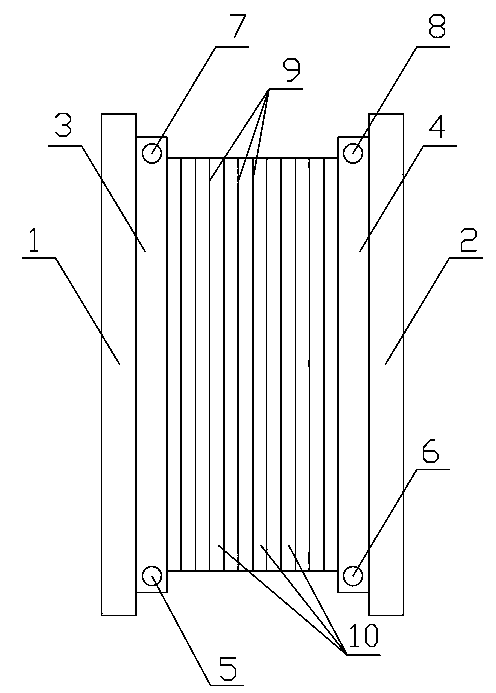

Image

Examples

Embodiment 1

[0046] A pretreatment process for cooking black liquor in the recovery of pulp by diffusion dialysis, adding a flocculant to the cooking black liquor with a sodium hydroxide concentration of 8g / L for flocculation, so that the concentration of the flocculant is 5mg / L, and then filtering The pore size of the cloth is 1100g / m 2 The plate and frame filter is filtered, and then filtered by an ultrafiltration membrane with a pore size of 20A° to reduce the concentration of large particles of impurities, recover lignin, and obtain a pretreatment solution for diffusion dialysis treatment of cation exchange membranes.

Embodiment 2

[0048] A pretreatment process for cooking black liquor in the recovery of pulp by diffusion dialysis, adding a flocculant to the cooking black liquor with a sodium hydroxide concentration of 30g / L for flocculation, so that the concentration of the flocculant is 10mg / L, and then filtering The pore size of the cloth is 1300g / m 2 The plate and frame filter is filtered, and then filtered by an ultrafiltration membrane with a pore size of 1000A° to reduce the concentration of large particles of impurities, recover lignin, and obtain a pretreatment solution for diffusion dialysis treatment of a cation exchange membrane.

Embodiment 3

[0050] A pretreatment process for cooking black liquor in the recovery of pulp by diffusion dialysis, adding a flocculant to the cooking black liquor with a sodium hydroxide concentration of 19g / L for flocculation, so that the concentration of the flocculant is 7.5mg / L, and then through The pore size of the filter cloth is 1200g / m 2 The plate and frame filter is filtered, and then filtered by an ultrafiltration membrane with a pore size of 510A° to reduce the concentration of large particles of impurities, recover lignin, and obtain a pretreatment solution for diffusion dialysis treatment of a cation exchange membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com