Anthraquinone hydrogenation catalyzer of anthraquinone method oxydol preparation process and its preparation method

A technology of hydrogen peroxide and anthraquinone method, applied in the chemical industry, can solve the problems of high production cost of hydrogen peroxide, hydrogen consumption, high price of palladium catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

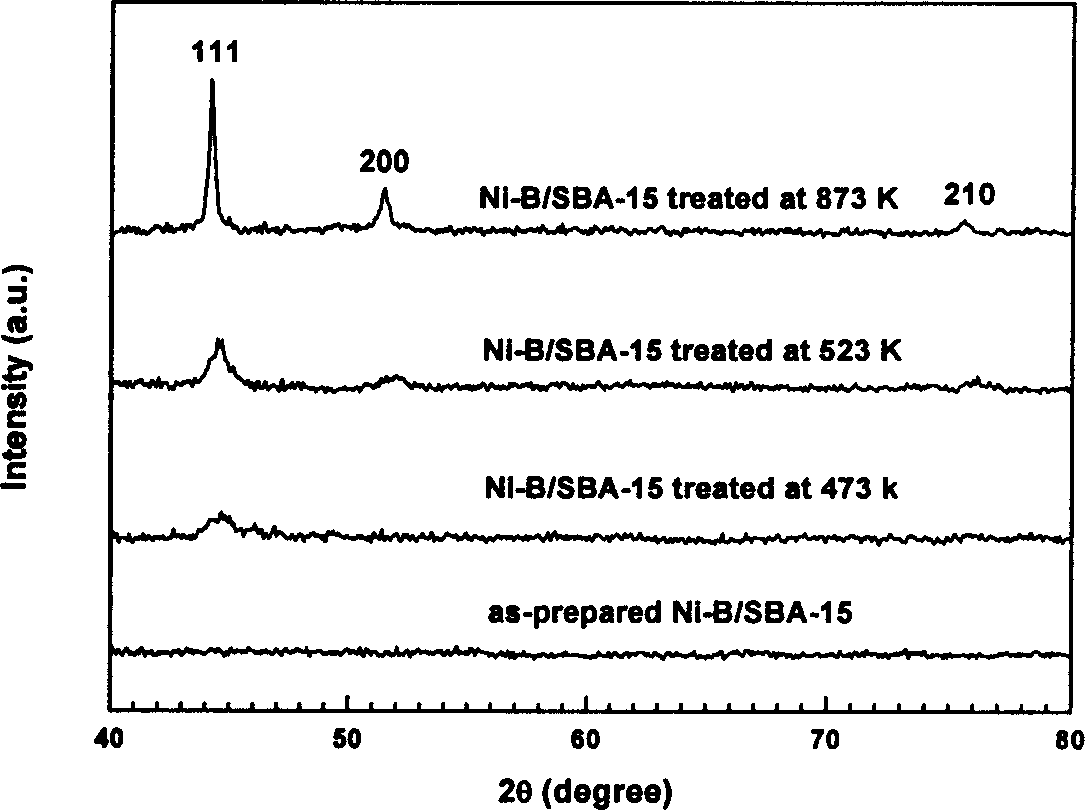

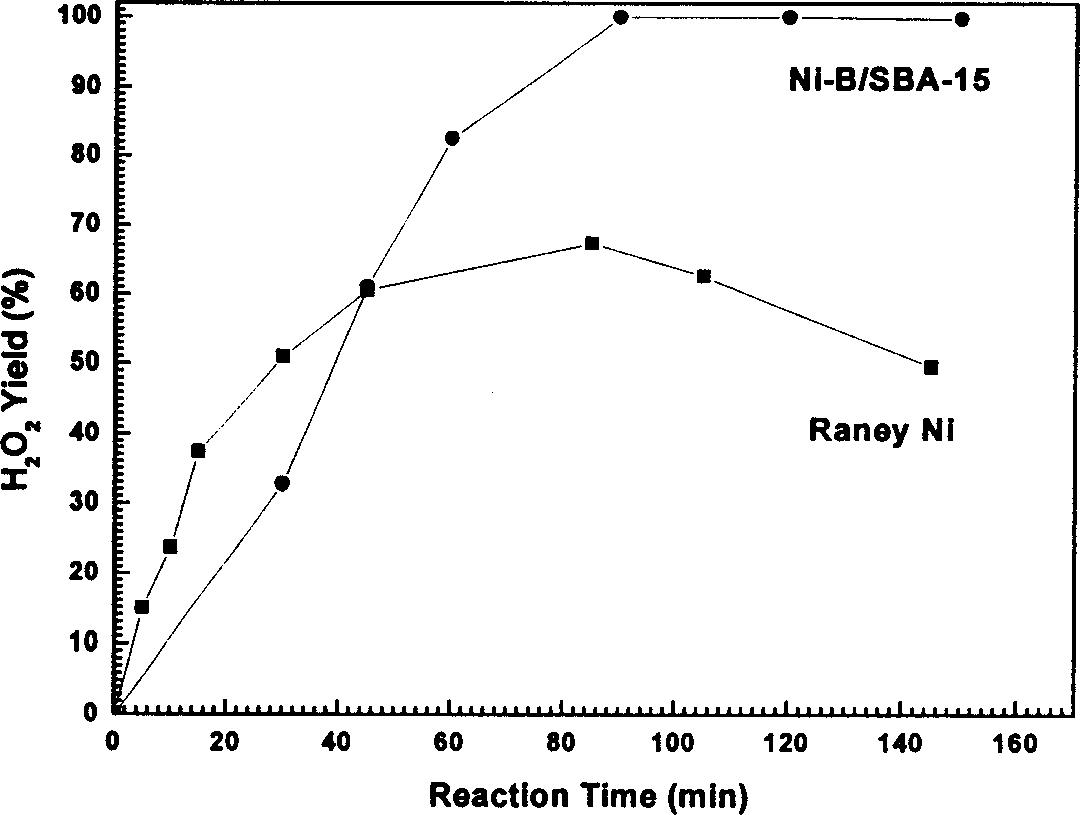

[0021] Example 1: Supported amorphous Ni-B / SiO by reducing agent impregnation method 2 Preparation of Alloy Catalyst

[0022] Take 1g SiO 2 Carrier (40-60 mesh), use 3M KBH 4 Immerse in the solution for 15 minutes, pour out the impregnation solution, and then add a certain volume of 0.42M NiCl at one time 2 solution, and then decant the KBH 4 The impregnating solution is dripped back, and the reaction is completed when no bubbles are generated. The obtained catalyst was first washed with distilled water to neutrality, and then washed with ethanol three times to replace the water. The catalyst was finally stored in ethanol for characterization and activity testing. Some characterization results of the catalysts are shown in Table 1.

Embodiment 2

[0023] Example 2: Common impregnation method supported amorphous N-B / SiO 2 Preparation of Alloy Catalyst

[0024] 1.0g SiO 2 (40-60 mesh, treated with nitric acid) 3.4mL 0.50M NiCl 2 ·6H 2 Immerse in O aqueous solution for 10 min, evaporate to dryness in a 70°C water bath with stirring, then bake in an oven at 120°C overnight, and then bake at 200°C for 2.0h. 6.8 mL of 1M KBH in an ice-water bath 4 The aqueous solution was reduced, and after the reaction was completed, it was washed with distilled water to neutrality, and then washed three times with absolute ethanol for later use. Partial characterization results of the catalysts are shown in Table 2.

Embodiment 3

[0025] Embodiment 3: According to the various operating conditions and steps of Embodiment 1, only the carrier is changed, and the results are listed in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com