Novel device for electrostatic spinning, bundling and twisting of nano yarns

A twisting device and electrospinning technology are applied in the field of air-assisted electrospinning bundle twisting nano-yarn devices, which can solve the problems of low twisting degree, inability to obtain area nanofiber bundles, fiber adhesion and the like, and achieve evenness. good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated in conjunction with specific embodiments. It will be appreciated that these examples are intended to illustrate the scope of the invention and are not intended to limit the scope of the invention. It will be appreciated that after reading the present invention, those skilled in the art can make various modifications or modifications of the present invention, which also fall in the scope of the claims appended claims.

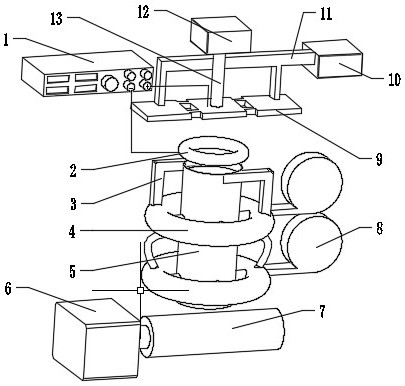

[0020] Refer to the attachment figure 1 Attachment figure 2 Attach image 3 One new type of electrostatic spun wiring body, nano yarn, which mainly includes a spray device (9), a metal ring electrode (2), a two-stage cyclone flow, a twisting device (5), collecting device (7) , High pressure generating device (1).

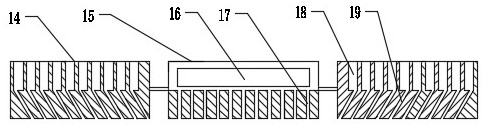

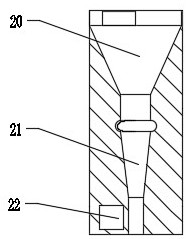

[0021] Wherein, the injection device (9) is divided into a jet device (15), the jet device (14), respectively, by the infusion tube (13), the gas pipe (11) and a solution tank (12), a high pressure gas st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com