Gearwheel and method for manufacturing a gearwheel

A gear and structure technology, applied in the field of gear and gear manufacturing, can solve problems such as unreliable deformation and poor torque synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

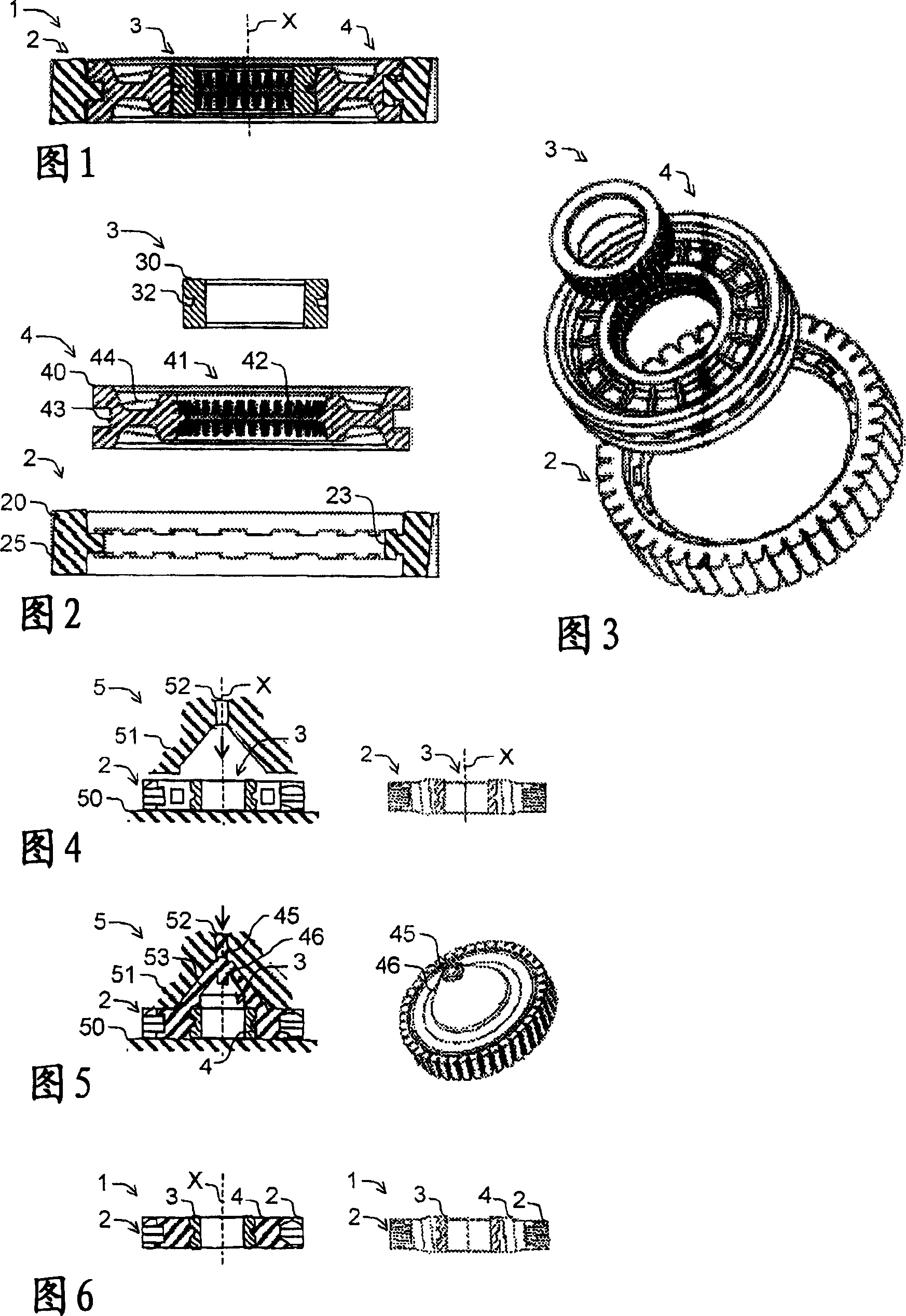

[0031] As shown in FIGS. 1-3 , an exemplary gear 1 is composed of a plurality of individual gear parts, wherein the gear 1 is exemplary composed of three parts. The gear wheel 1 has on the side an outer part 2 which forms the actual toothed ring. In this case, the outer part 2 is preferably dimensioned very thinly or with little extension in the radial direction. The gear wheel 1 has an insertion 3 on the inside, usually an insertion 3 designed as a hub. While the outer part 2 is preferably produced from a relatively soft plastic material, as is known per se for gears, the insert 3 is preferably designed as a metal hub, for example a steel hub, as is likewise known per se.

[0032] The outer circumference of the insertion part 3 is spaced apart from the inner circumference of the outer part 2 so that they can be releasably interleaved in the mold. The connection between the insertion part 3 and the outer part 2 is carried out through the connection part 4 to connect the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com