Sealing method for laser filler welding of hybrid integrated circuit package

A hybrid integrated circuit and laser technology, applied in laser welding equipment, circuits, welding equipment, etc., can solve the problems of high thermal cracking tendency and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

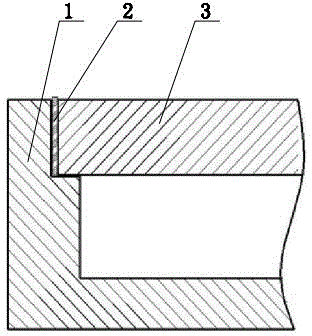

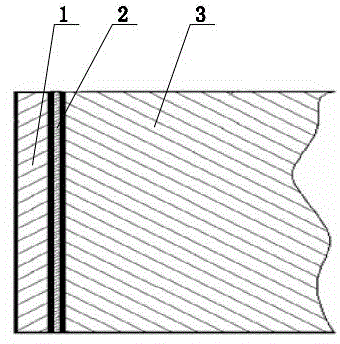

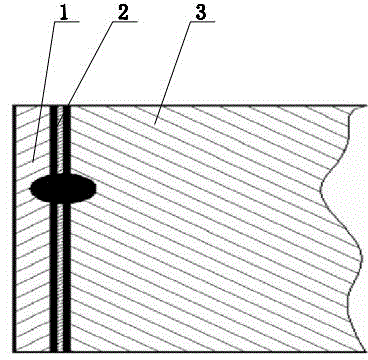

[0028] like figure 1 As shown, the sealing method of the laser filler welding of the hybrid integrated circuit package in this embodiment includes the following steps:

[0029] The first step: cleaning the aluminum alloy shell 1 and the aluminum alloy cover plate 3 with acetone;

[0030] The second step: joint assembly: the aluminum alloy shell 1 is provided with a step-shaped groove, and the aluminum alloy cover plate 3 is installed on the aluminum alloy shell 1, and the aluminum alloy shell 1 and the aluminum alloy cover plate 3 are docked by tooling , the butt joint method is a corner joint, and a joint gap is formed at the joint;

[0031] Step 3: Fill the prefill 2 in the joint gap;

[0032] The fourth step: spot welding: use Nd:YAG laser to fix the relative position of aluminum alloy shell 1, aluminum alloy cover plate 3 and prefil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com