Production technique for wheat straw fiber brake disc friction materials

A production process and technology of friction materials, applied in the direction of friction linings, other chemical processes, chemical instruments and methods, etc., to achieve the effects of dense structure, improved thermal decay and hardness, good cushioning and rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

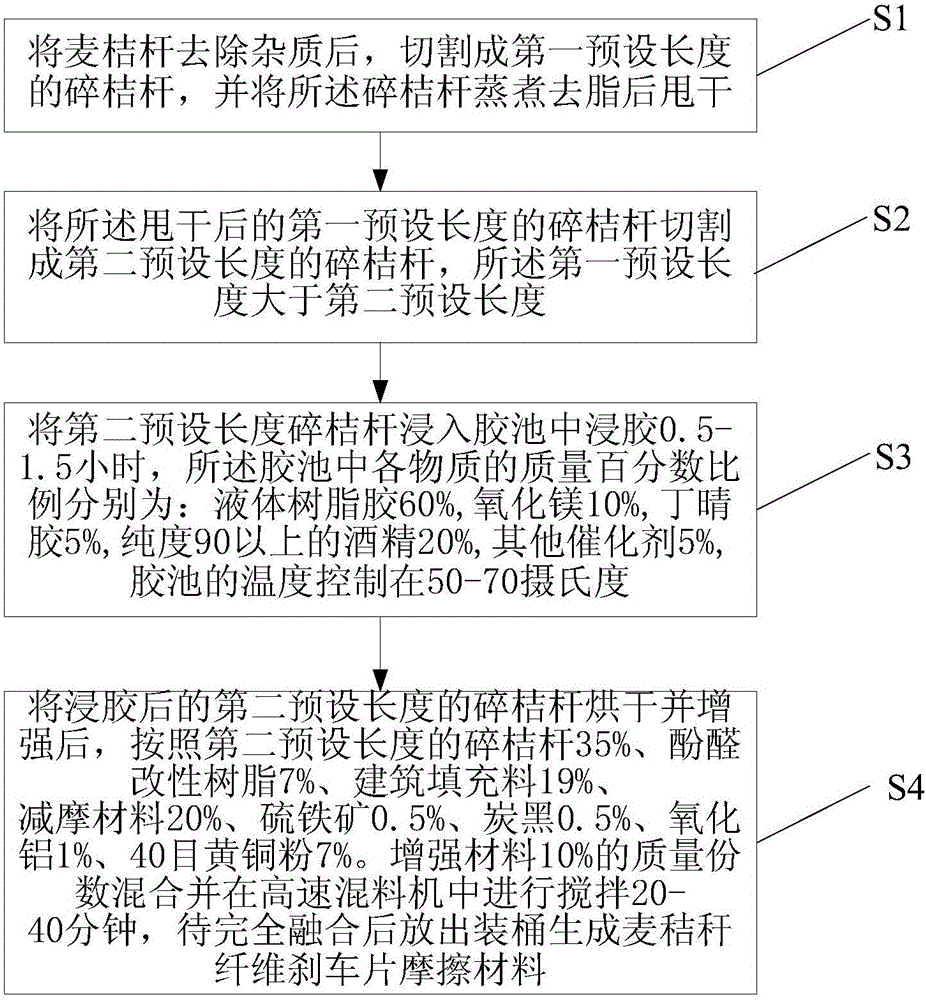

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] see figure 1 . The production process of the wheat straw fiber brake pad friction material in the preferred embodiment of the present invention comprises steps:

[0019] S1: After removing impurities from the wheat stalks, cutting them into broken stalks of a first predetermined length, cooking the broken stalks to remove fat, and drying them;

[0020] In this step, the wheat straw is dried in the sun, the mud is removed, the roots are removed, and then cut off, and the wheat straw is cut into a first predetermined length, the first predetermined length is not more than 10 cm in length, steamed and degreased, then dried during the drying process The time is controlled at 5 hours.

[0021] S2: cutting the dried orange stalks of the first preset length into broken orange stalks of a second preset length, the first preset length being gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com