Brake pad for disc brake

A disc brake and brake pad technology, applied in the field of brake pads, can solve the problems of reduced moisture resistance of brake pads, uneven wear of brake pads, poor braking force stability, etc., so as to improve braking stability and improve working environment. Temperature, effect of increasing braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

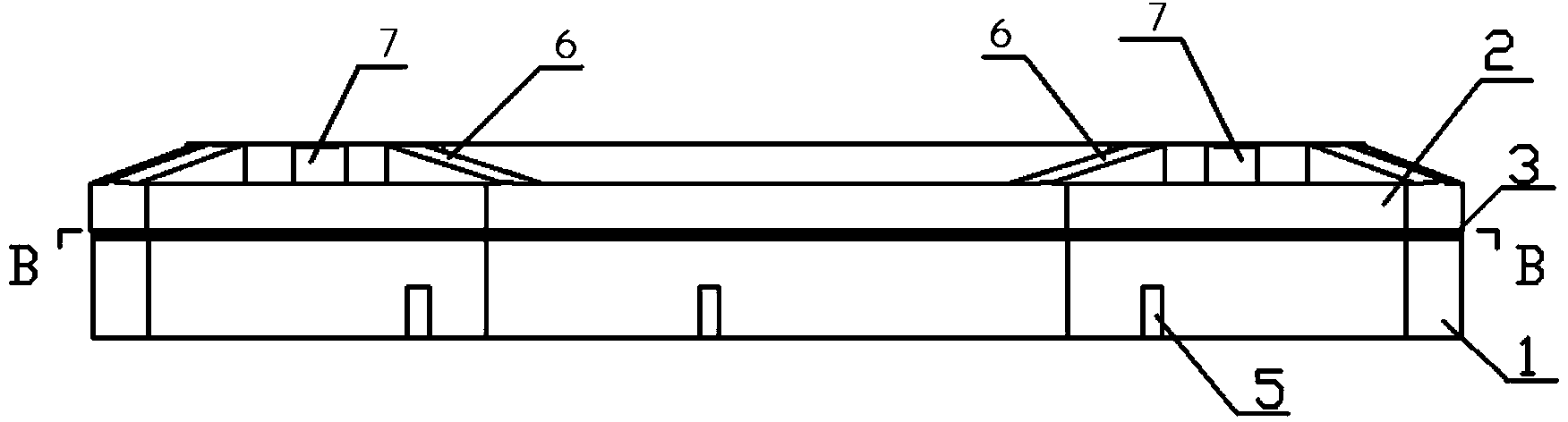

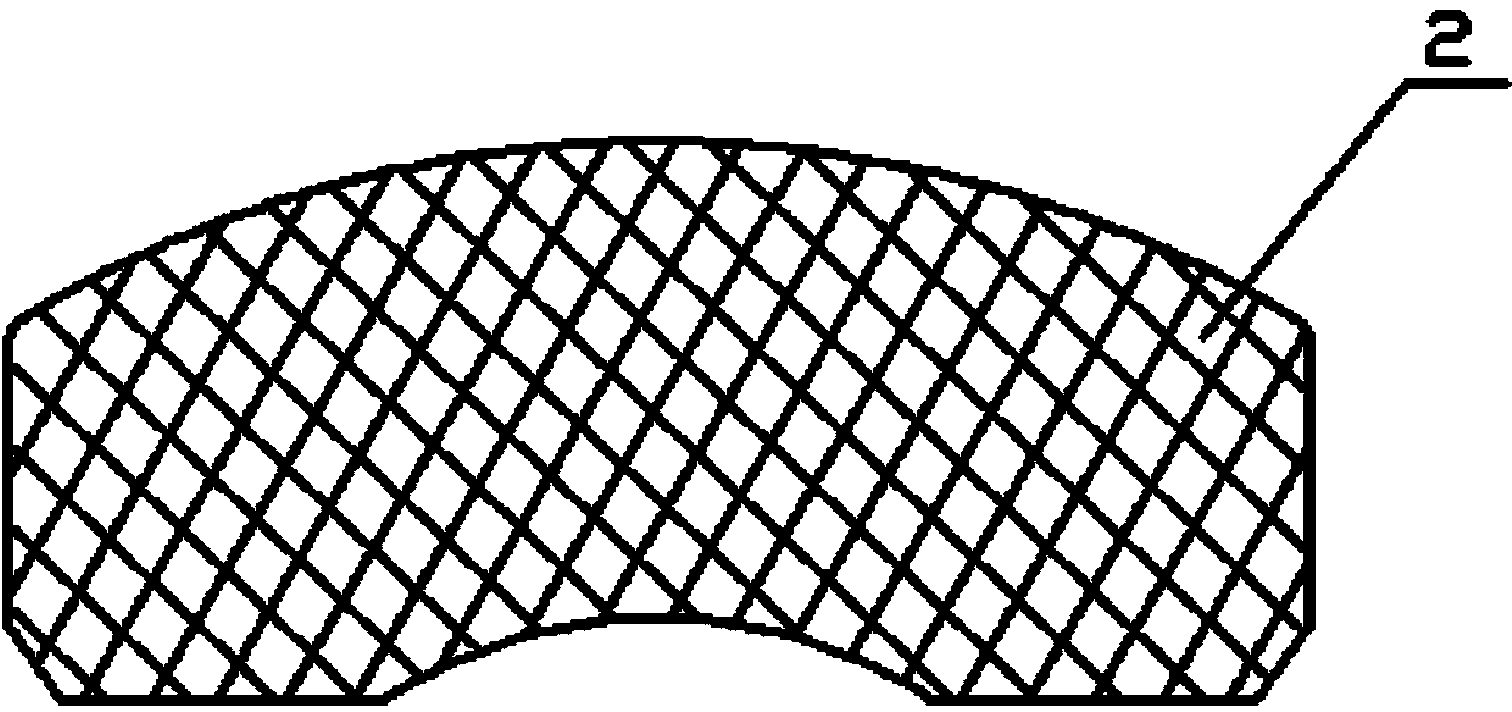

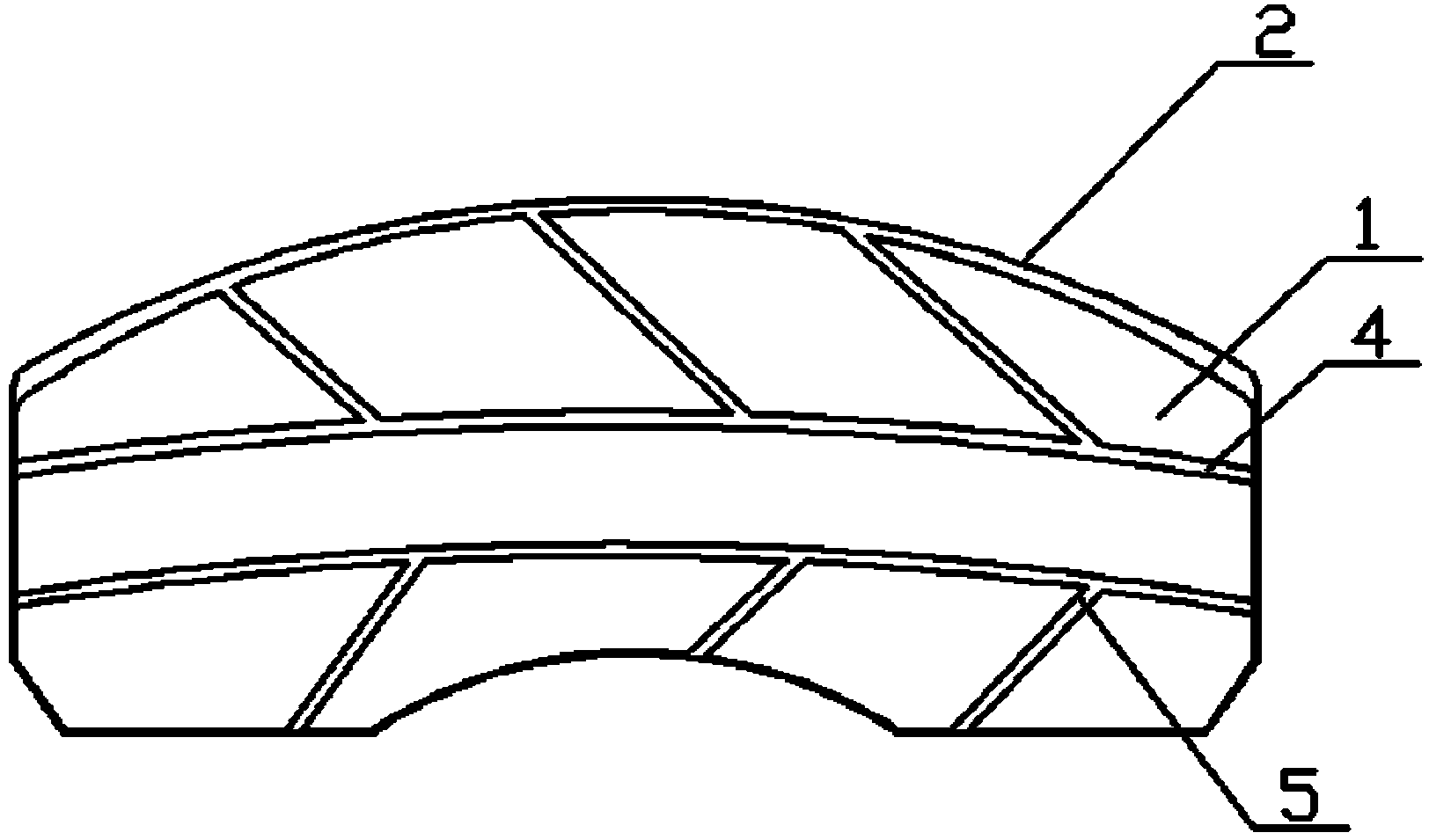

[0026] like figure 1 As shown, a brake pad for a disc brake includes a friction layer 1 and a steel back layer 2, the friction layer 1 and the steel back layer 2 are fan-shaped, the steel back layer 2 is located above the friction layer 1, and passes through the metal Binder 3-phase bonding, such as figure 2 as shown, figure 1 The cross-sectional view of B-B of the steel back layer 2 and the friction layer 1 is engraved with a layer of diamond-shaped mesh grooves. The diamond-shaped mesh grooves can increase the bonding strength between the friction layer 1 and the steel back layer 2, thereby effectively reducing The problem of the reduction of the bond strength between the friction layer 1 and the steel back layer 2 caused by the long-term braking process is solved.

[0027] like image 3 As shown, the braking surface of the friction layer 1 is provided with seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com