Multi-brake-shoe drum brake and working method

A drum brake and multi-brake technology, applied in the direction of drum brakes, combined drum brakes, brake types, etc., can solve the problem of poor braking efficiency and heat dissipation of drum brakes, inability to rapidly increase braking force, and no simultaneous realization Brake and other problems, to achieve good comfort and NVH performance, reasonable force, good braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

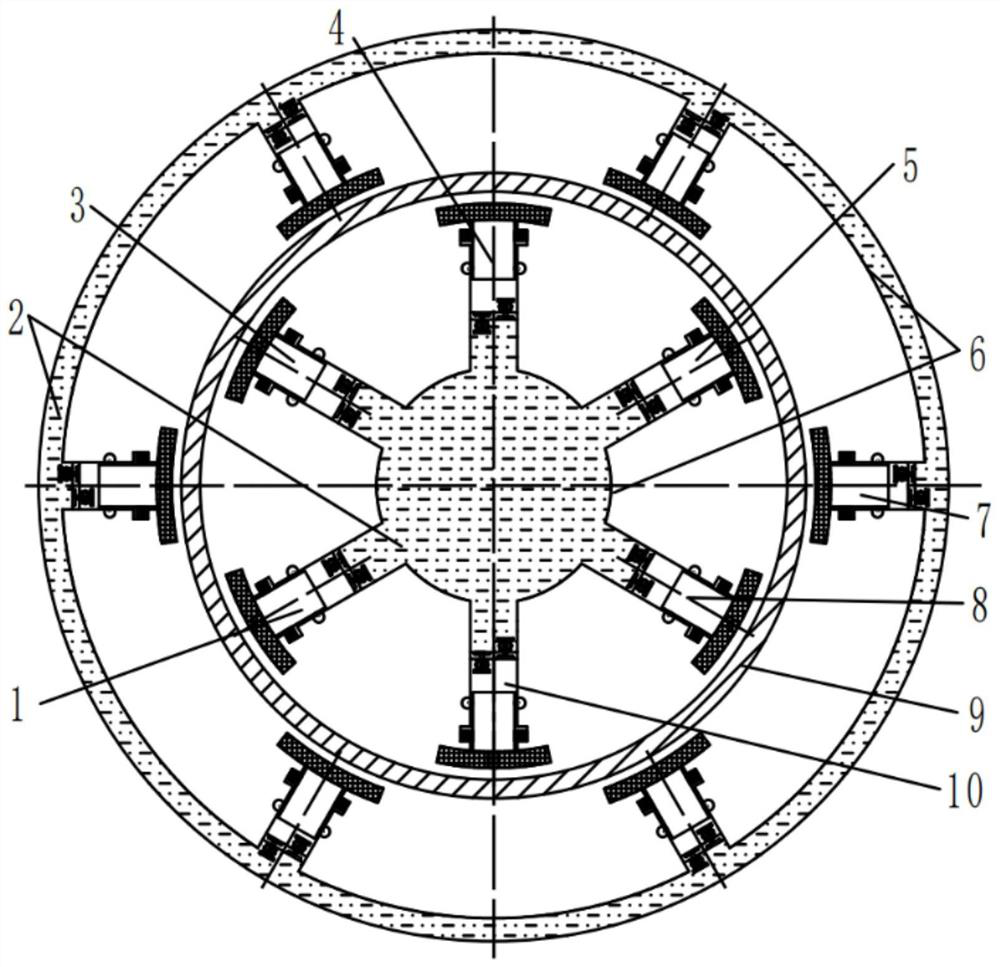

[0031] Such as figure 1 As shown, the multi-brake shoe drum brake of the present invention includes a first internal tension type brake mechanism 1, oil liquid 2, a second internal tension type brake mechanism 3, a third internal tension type brake mechanism 4, a first internal tension type brake mechanism Four inner tension brake mechanisms 5 , a brake bottom plate 6 , an outer beam brake mechanism 7 , a fifth inner tension brake mechanism 8 , a brake drum 9 and a sixth inner tension brake mechanism 10 .

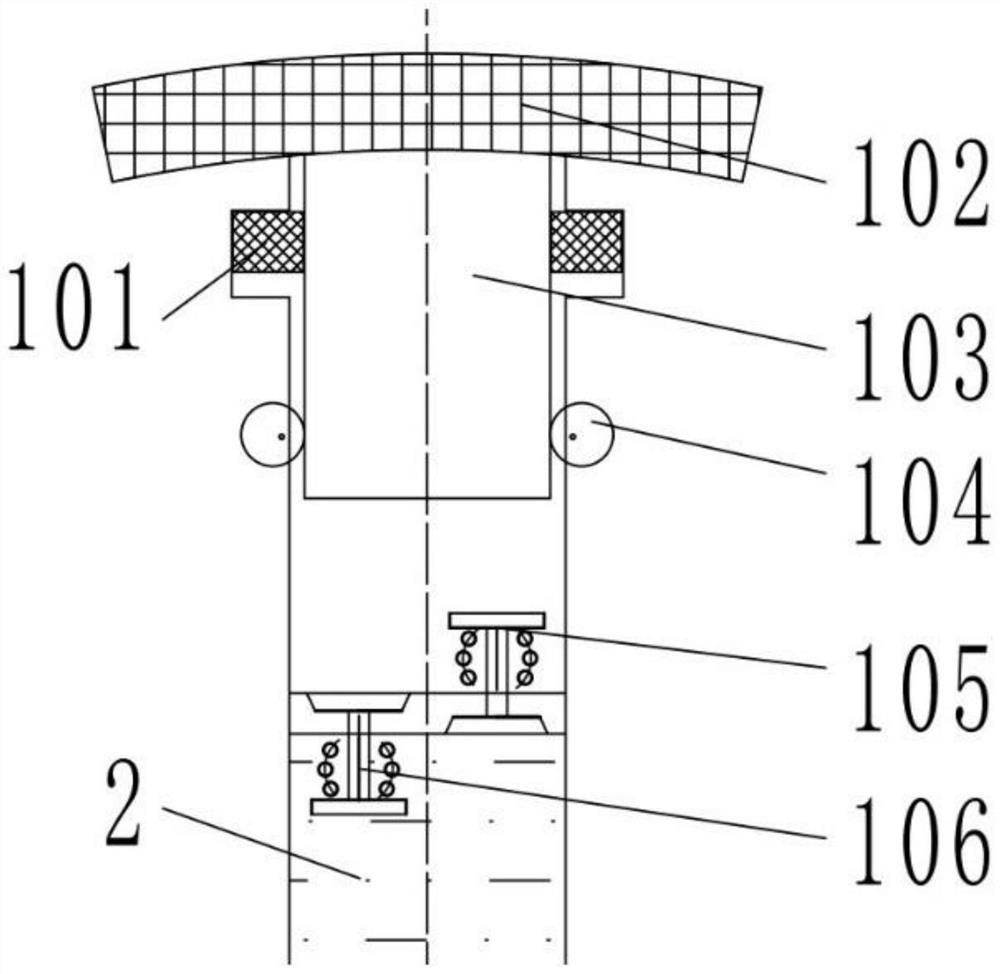

[0032] Such as figure 2 As shown, the first internal tension type brake mechanism 1 includes a rectangular sealing ring 101 and a piston 103. The inner wall of the brake base plate 6 is provided with a trapezoidal cross-section ring groove, in which the rectangular sealing ring 101 is embedded to realize the sealing, return and return of the piston 103. Clearance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com