Unlimited rotation automatic clamping mechanism used for full automatic balance correcting equipment

A technology of a balanced correction and a clip -holding mechanism is applied in the direction of adjustment in the middle/balance rotor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with drawings and embodiments.

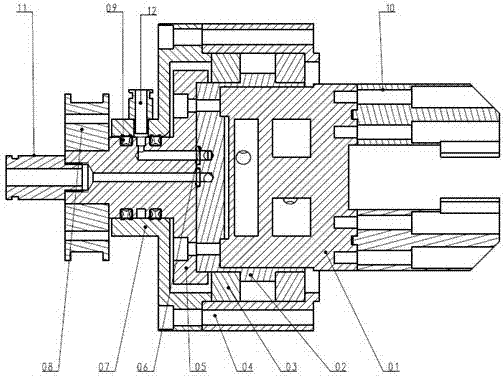

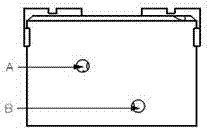

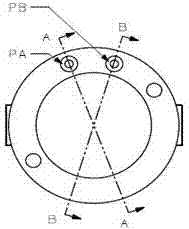

[0037] Such as figure 1 , Figure 6As shown, the present invention includes air claw 01, air claw sleeve 02, rotating mechanism outer cylinder 04, rotating shaft 05, rotating shaft sleeve 07, synchronous pulley 08, air claw finger 10, small frictional resistance rotating air joint 11 and Ordinary air joint 12; the air claw 01 is fixed in the center hole of the air claw sleeve 02, the air claw sleeve 02 is fixed on the outer cylinder 04 of the rotating mechanism through the bearing 03, one end of the air claw 01 is connected with the air claw finger 10, and the rotating shaft One end of 05 is fixed in the air gripper sleeve 02 away from the gripper finger 10, the other end of the rotating shaft 05 is covered with a rotating shaft sleeve 07, and two star-shaped sealing rings are used between the rotating shaft 05 and the rotating shaft sleeve 07 09 seal, there is an ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com