Sealing assembly for wheel hub bearing unit

A technology for sealing components and hub bearings, applied to bearing components, bearings, shafts and bearings, etc., can solve the problems of accelerated channel and steel ball wear, poor sealing performance, abnormal noise of bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

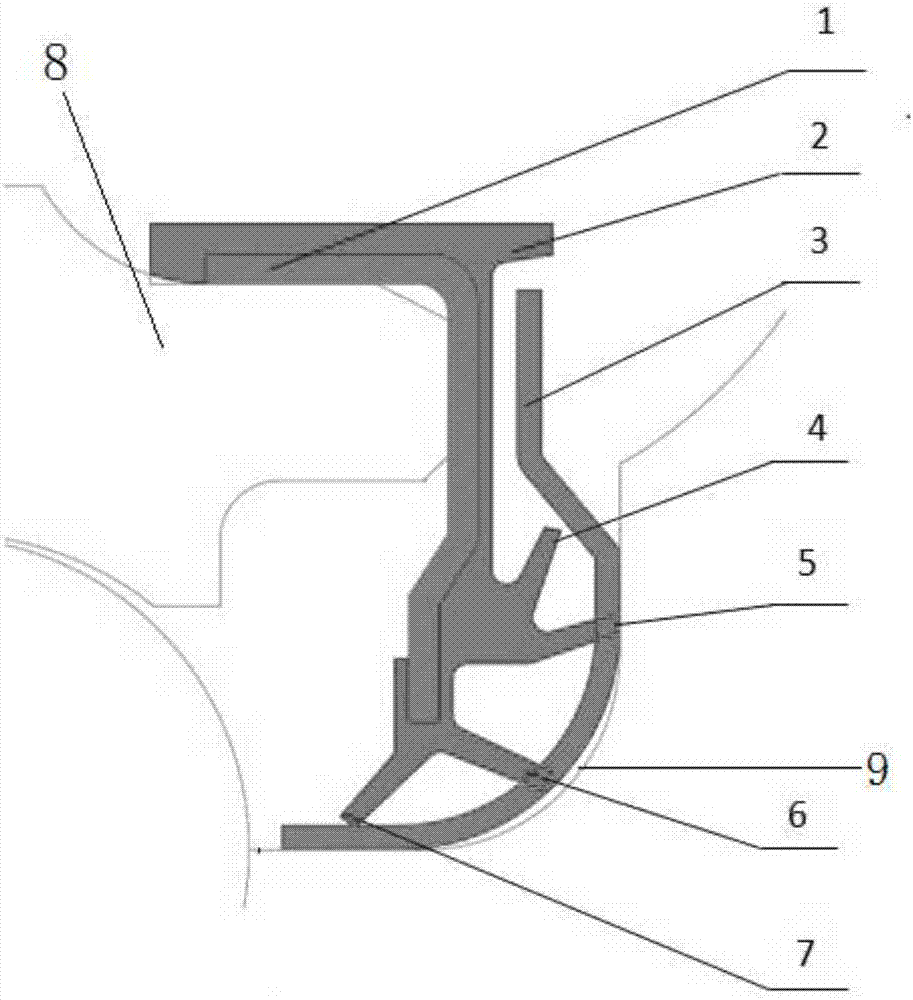

[0017] as attached figure 1 As shown, the present invention provides a new type of sealing assembly for hub bearing units, including rubber protrusions 2 attached to the skeleton 1, stainless steel skeleton 3, lip one 4, lip two 5, lip three 6, lip Four 7; rubber protrusions, lip 1, lip 2, lip 3, and lip 4 are a whole single-piece structure attached to the skeleton; skeleton 1 is installed on the outer ring of the hub 8, and the stainless steel skeleton 3 is installed on the hub On the flange 9; there is a gap between the lip 1 and the stainless steel frame 3 in the natural state; the rubber protrusion 2 protrudes above the top of the stainless steel frame 3, and the lip 2, lip 3, and lip 4 are in the natural state The bottom is in contact with the stainless steel frame. The design of this invention uses the rubber protrusions attached to the frame to prevent the external muddy water from flowing directly into the lip from the upper side. The stainless steel frame blocks the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com