Torsional Damper With Angular-Dependent Friction Damping Device

A torsional shock absorber and friction device technology, which is applied in the direction of shock absorbers, friction clutches, springs/shock absorbers, etc., can solve problems such as radial structural space limitations and wear volume limitations, and achieve the effect of increasing friction torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

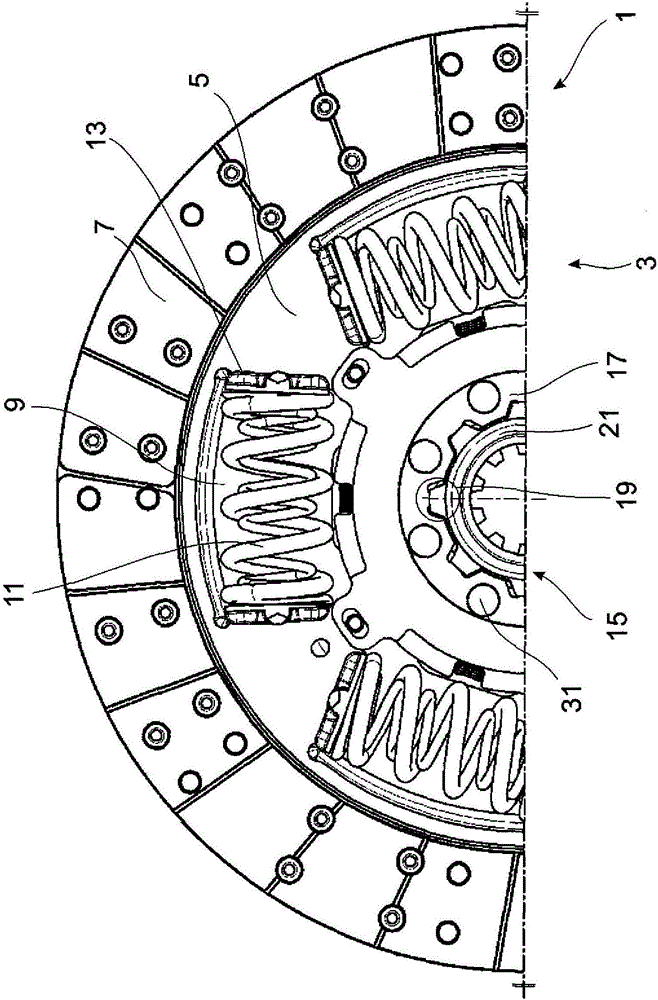

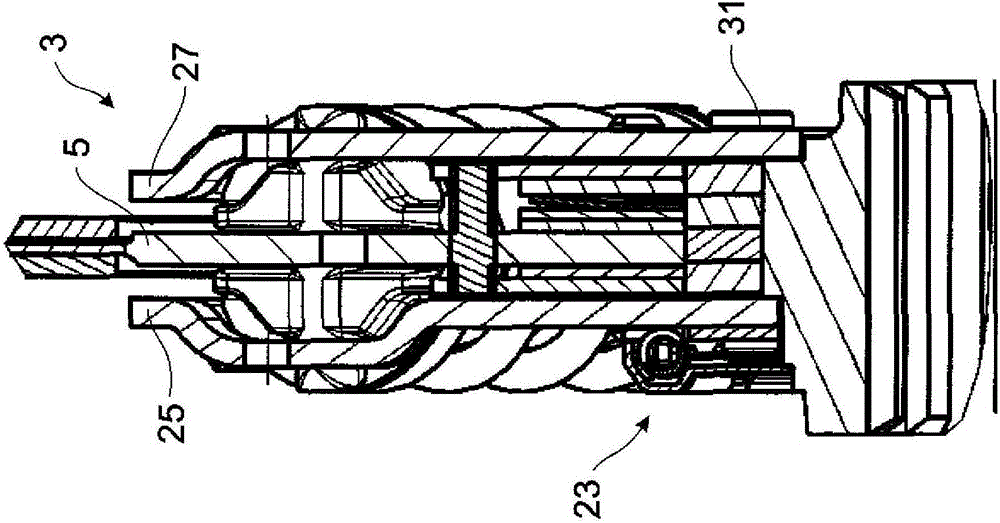

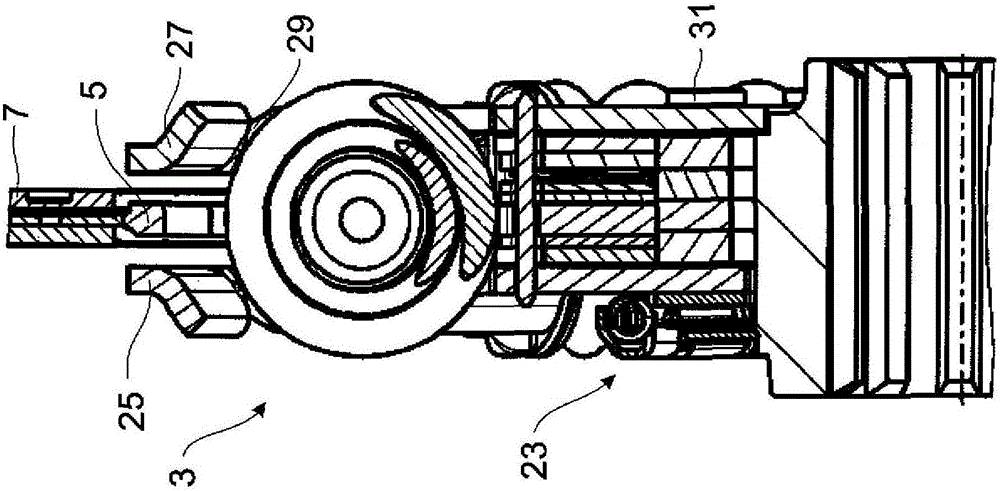

[0027] figure 1 A front view of a partially assembled clutch disk 1 with a torsional vibration damper 3 is shown. In principle, the torsional vibration damper can also be used outside the clutch disc. combine figure 2 and image 3 It can be clearly seen that the torsional vibration damper 3 has a torque input disk 5 which carries the friction lining 7 . On this torque input disc 5 , for example, the torque of the drive motor is transmitted via a clutch housing (not shown) to the friction linings.

[0028] The torque input disc 5 has a window-like recess 9 in which at least one spring energy store 11 , for example a helical compression spring, is arranged. In this example, a support disk 13 is inserted between the end turn of the helical compression spring 11 and the notch 9 .

[0029] The torque input disk 5 is centered on its inner diameter relative to the torsional vibration damper hub 15 . By way of example, the torsional damper hub 15 is designed as a split, in whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com