Thrust mushroom-shaped part and motor with the thrust mushroom-shaped part

A mushroom-shaped, component-like technology, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve problems such as weak automatic braking, and achieve the effects of improving automatic braking, uniform friction torque, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

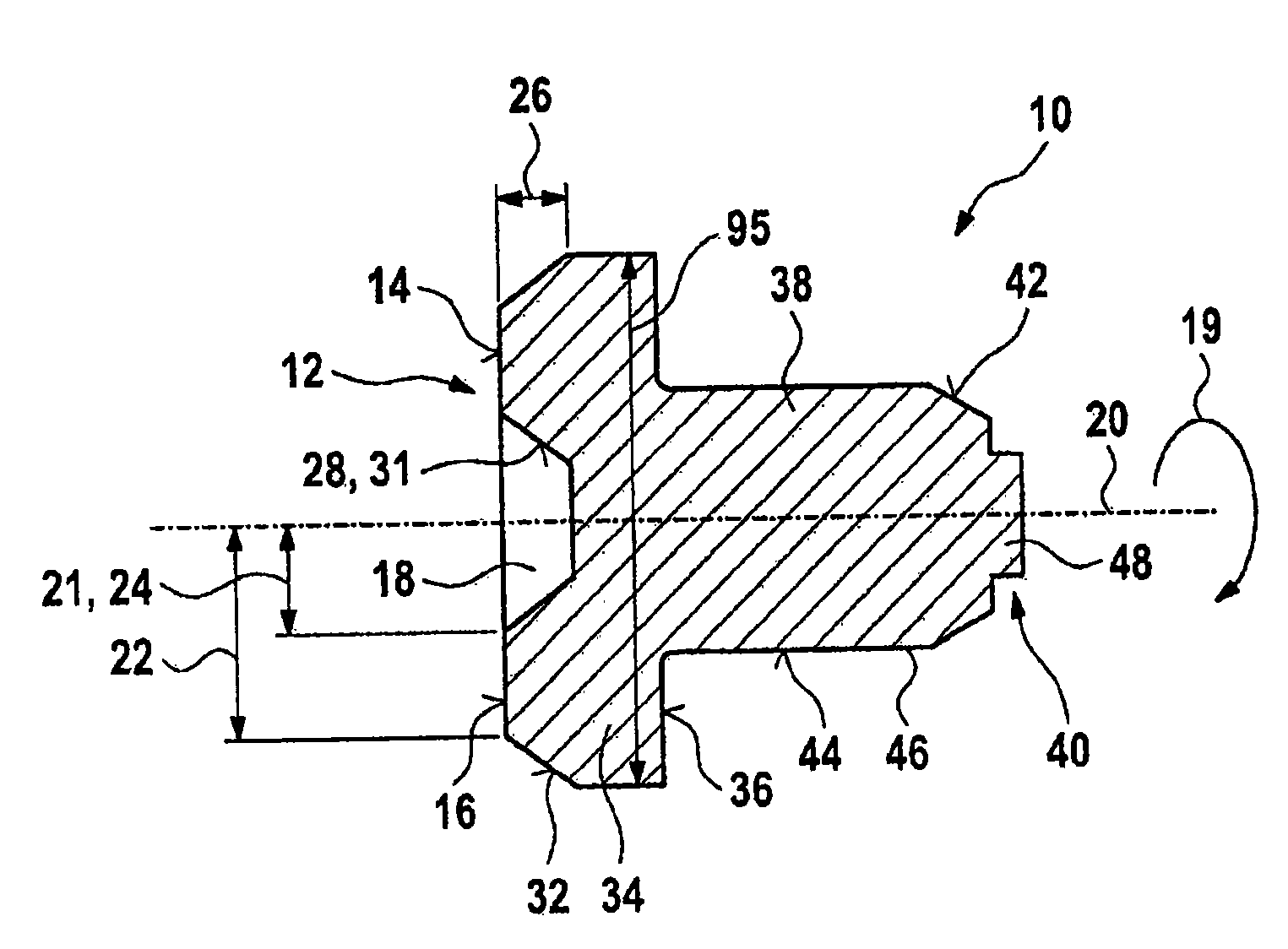

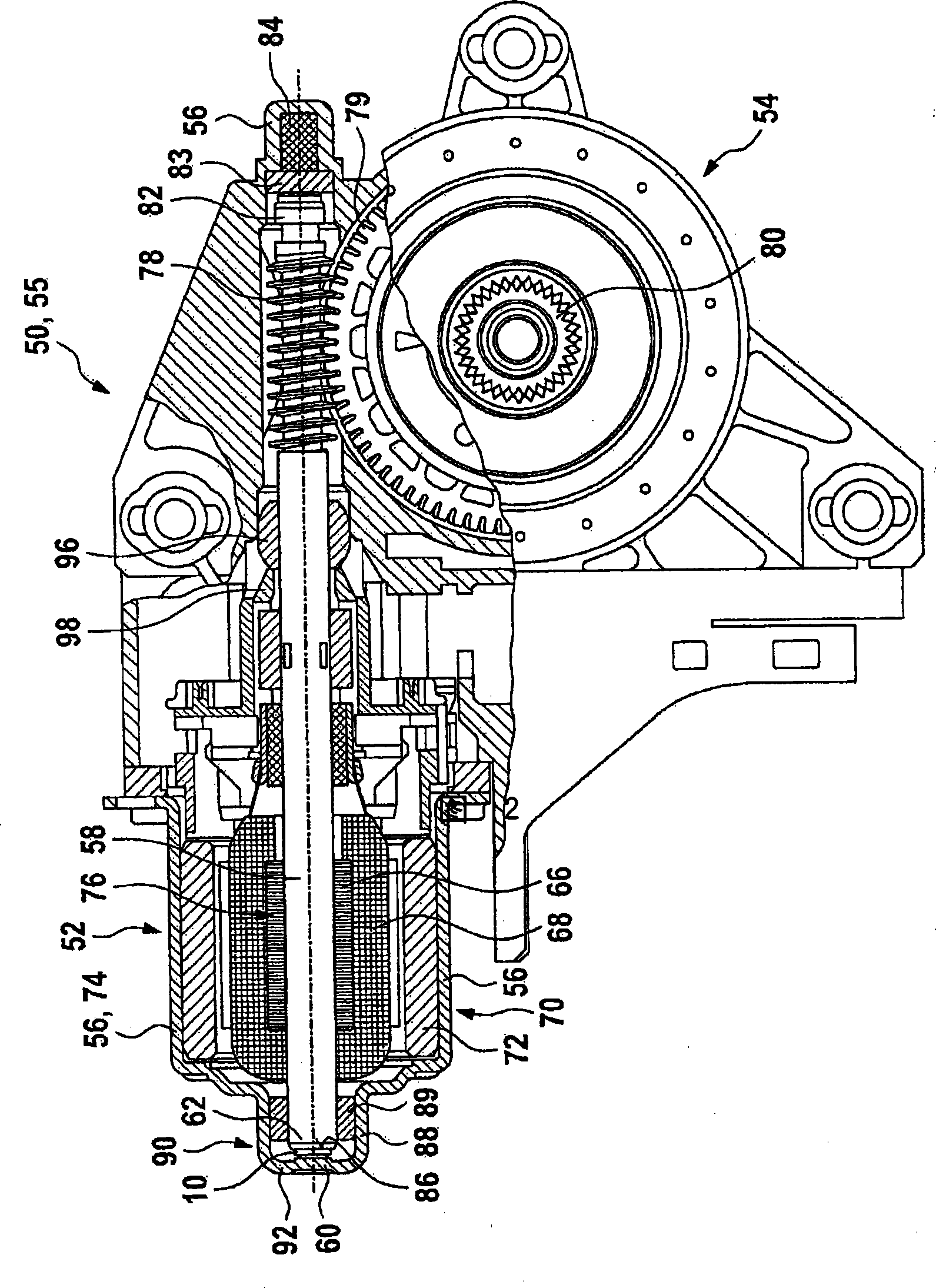

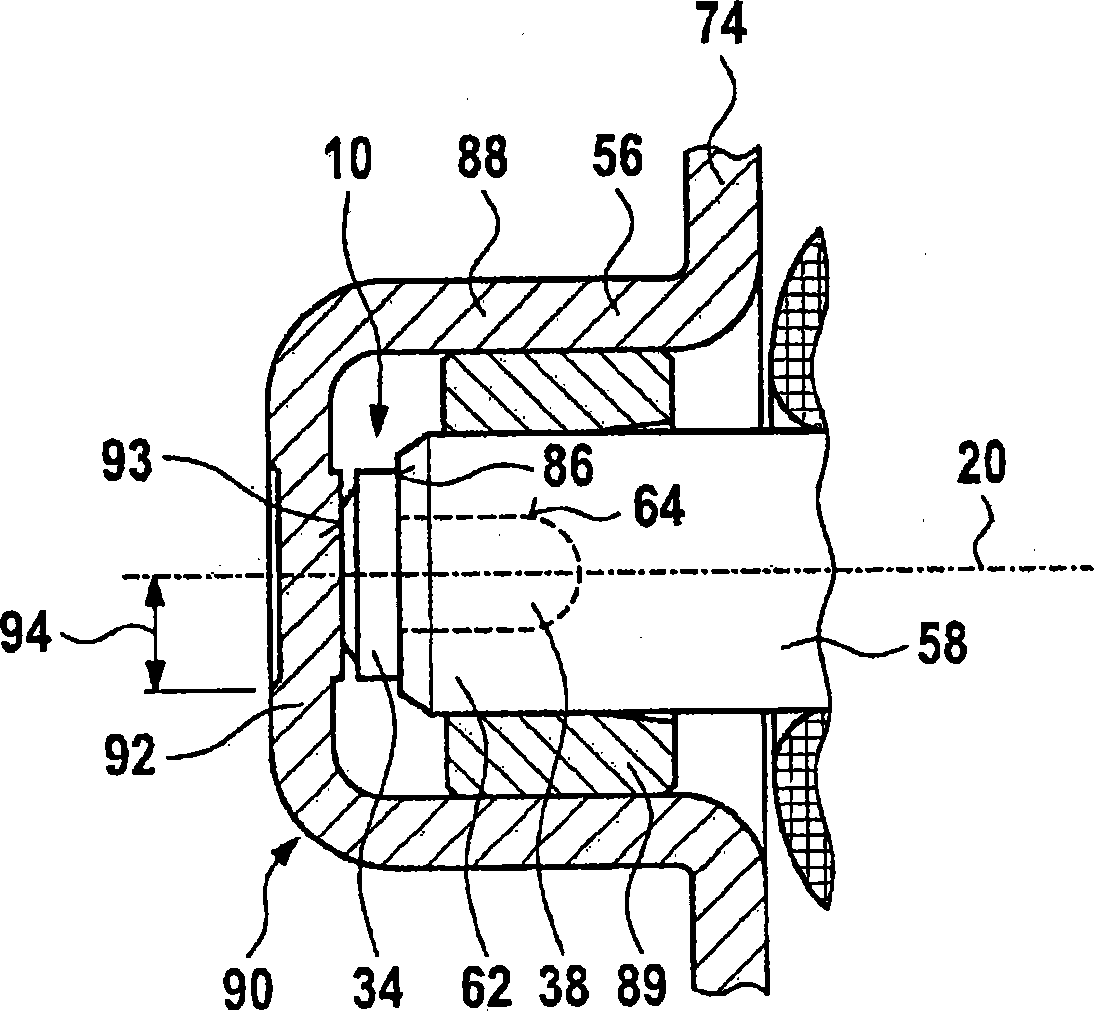

[0019] exist figure 1 A thrust mushroom 10 according to the invention is shown in , as it is used to axially support a rotor shaft 58 of an electric machine 50 . The thrust mushroom 10 has an end face 12 which, in the assembled state, points towards the mating face 60 of the housing 56 of the electric motor 50 . A thrust surface 14 is formed on the end face 12 and is arranged at a distance from the axial center axis 20 of the thrust mushroom 10 . The contact surface 14 is designed as a circular ring 16 with an inner radius 21 and an outer radius 22 which are, for example, approximately 1.2 mm and approximately 2.4 mm. Formed radially within the annular contact surface 14 is a recess 18 whose outer radius 24 on the end face 12 corresponds to the inner radius 22 . The groove 18 preferably has a depth 26 of 0.5 mm to 1.5 mm and is suitable, in the installed state, as a container for a lubricant to lubricate the thrust surface 14 . In this exemplary embodiment, the recess 18 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com