Oil lubricating roll-slide bearing with elastic roller

A lubricating and elastic technology, applied in rolling contact bearings, bearing components, shafts and bearings, etc., can solve problems such as good impact support and achieve the effect of low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention will be further illustrated by the following examples.

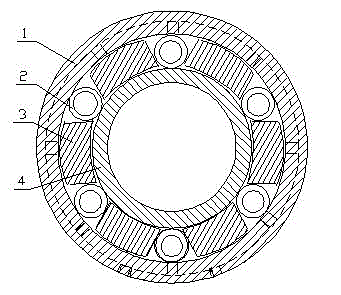

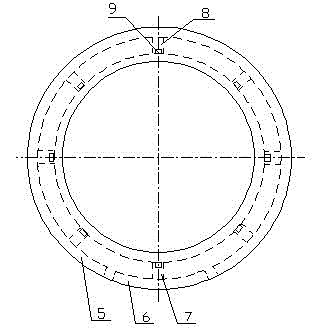

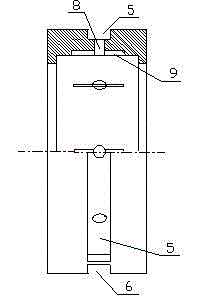

[0035] This embodiment consists of an outer ring (1), elastic cylindrical rollers (2), a slider (3) and an inner ring (4). Elastic cylindrical rollers (2) and sliders (3) are located in the chute between the outer ring (1) and inner ring (4); the number of elastic cylindrical rollers and sliders is equal, and they are separated from each other; The diameter of the roller is larger than the thickness of the slider in the radial direction of the bearing, and the axial length of the elastic cylindrical roller is smaller than the length of the slider in the axial direction of the bearing; the elastic cylindrical roller has a certain pre-compression in the diameter direction, and the slider and the inner ring There is a slight gap between the outer ring and the elastic cylindrical roller and the slider to maintain contact. The rolling bearing is lubricated by circulating oil, and the oil supplied from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com