Steering gear

A technology of steering mechanism and deflection shaft, which is applied in steering mechanism, power steering mechanism, electric steering mechanism, etc., and can solve problems such as different steering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

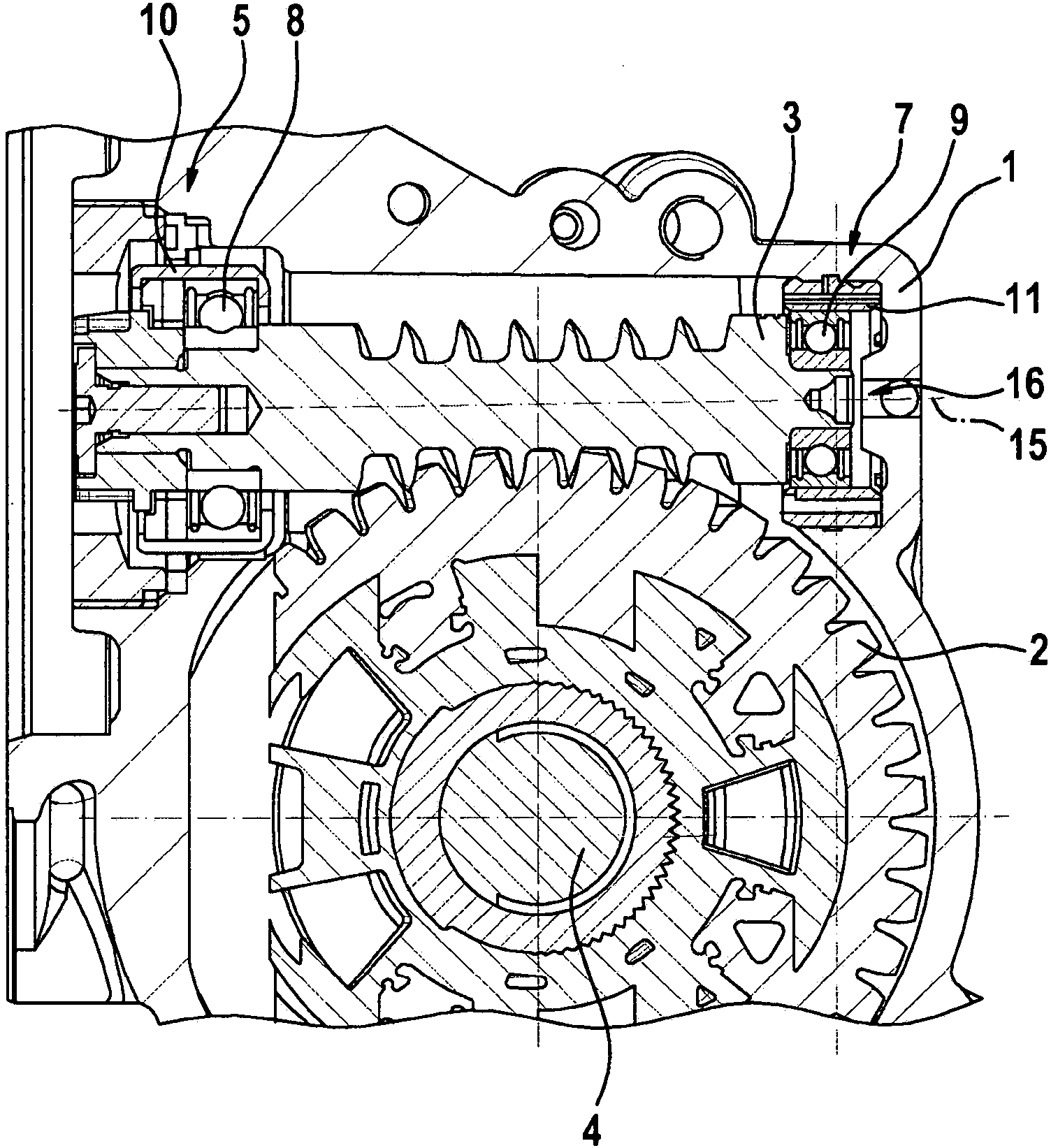

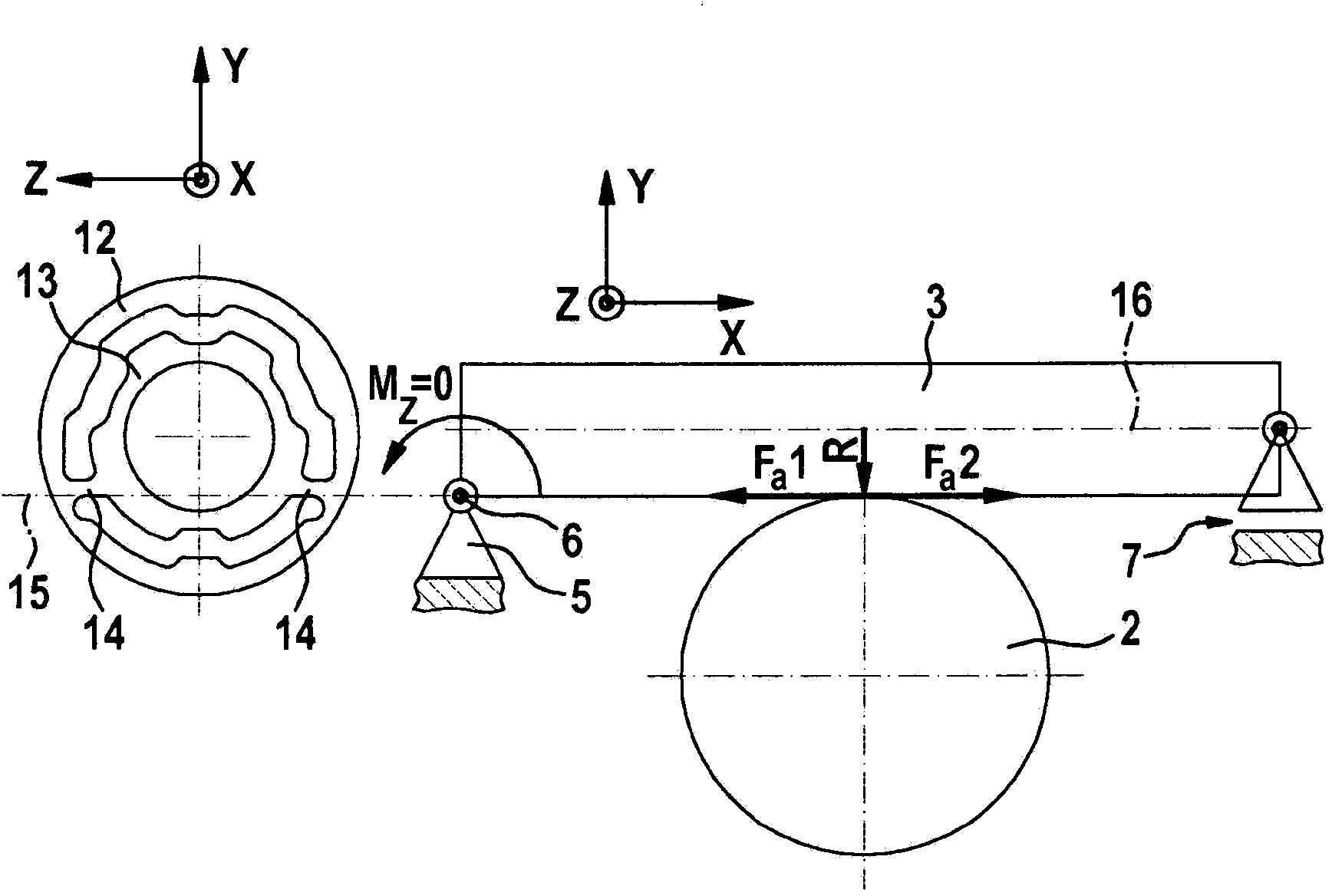

[0034] figure 1 The main components of an embodiment of the steering gear according to the invention are shown. The steering mechanism comprises a housing 1 in which a gear 2 and a pinion 3 meshing with the gear 2 are mounted. The pinion 3 and the pinion shaft containing the pinion are formed integrally in the form of a worm.

[0035] The gear 2 is fixed firmly on the steering column 4 of the car.

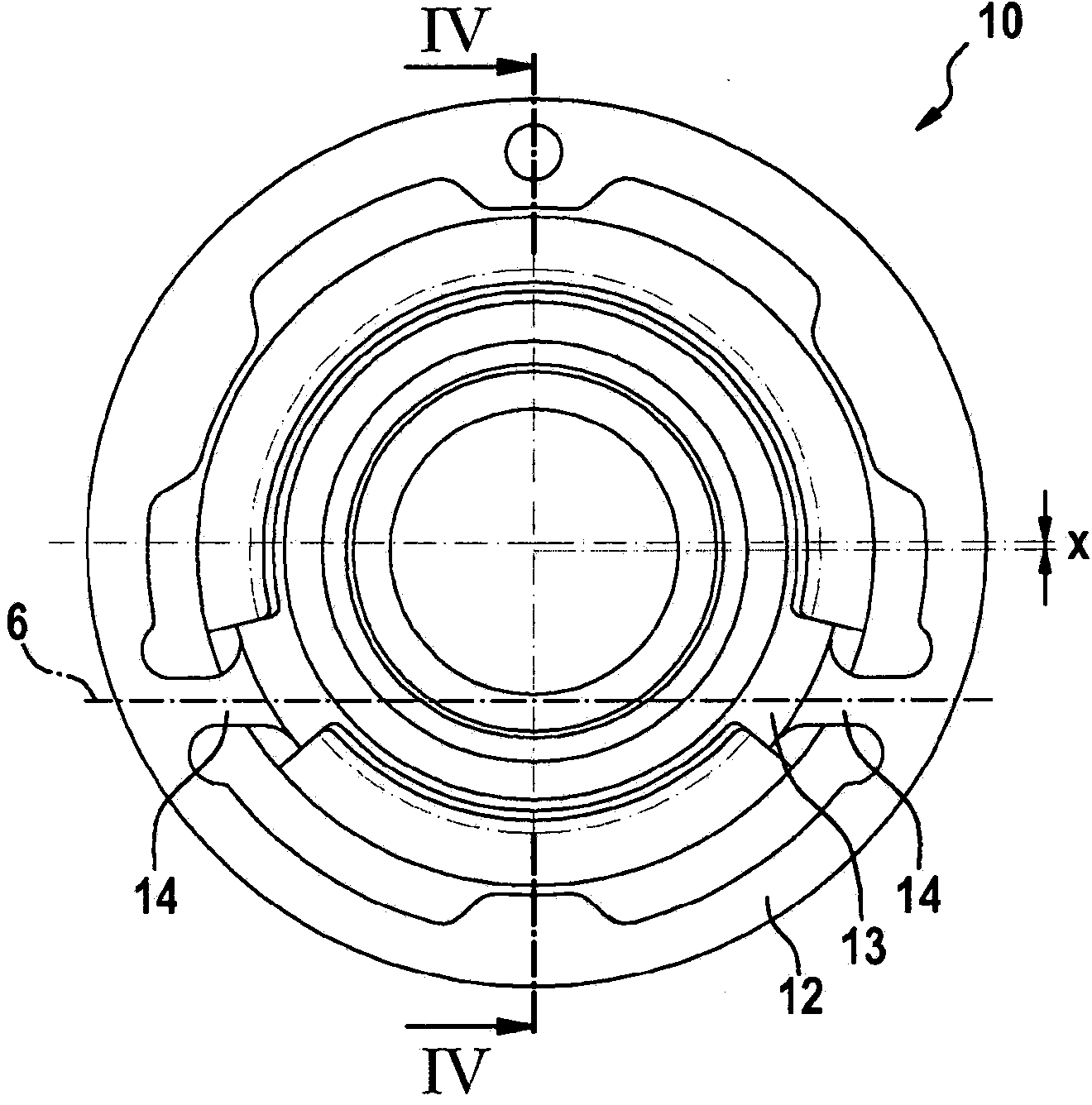

[0036] The pinion 3 has a drive-side end via which the pinion can be connected to an output shaft of a drive (not shown), for example an electric motor. In the region of this end on the drive side, the pinion 3 is mounted in the housing by means of a first bearing. This bearing is designed as a fixed bearing 5 , which essentially does not allow translation of the pinion 3 relative to the housing 1 , but permits a deflection about the deflection axis 6 .

[0037] This deflection causes a deflection of the free end of the end opposite the drive side of the pinion 3 , where the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com