Housing cover, in particular plastics oil sump

A casing cover and casing technology, which is applied to casings, transmission parts, engine components, etc., can solve the problems of expensive components, increased component weight and assembly costs, and increased numbers, and achieves small external dimensions and reduced costs. , the effect of construction space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

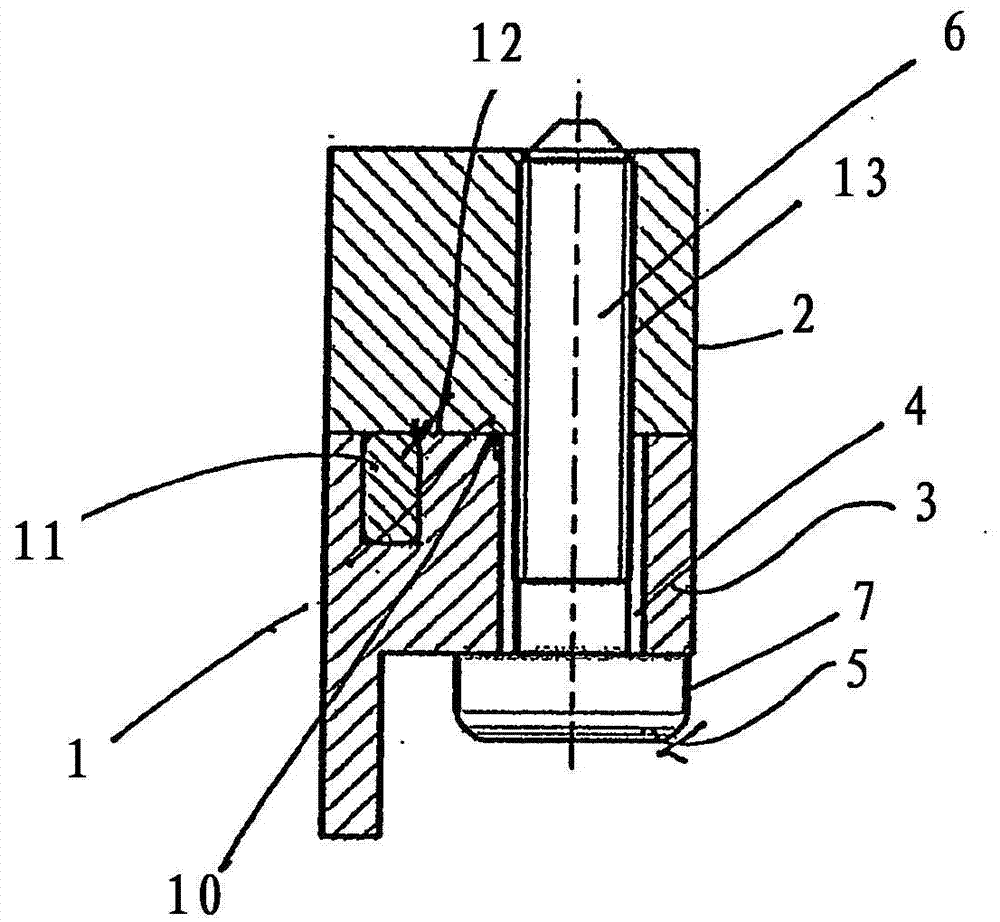

[0037] In the figures, the housing cover in the form of an oil sump 1 made of thermoplastic for a gearbox housing 2 on an internal combustion engine is not shown in its entirety, but only a partial section in the area of the screw connection .

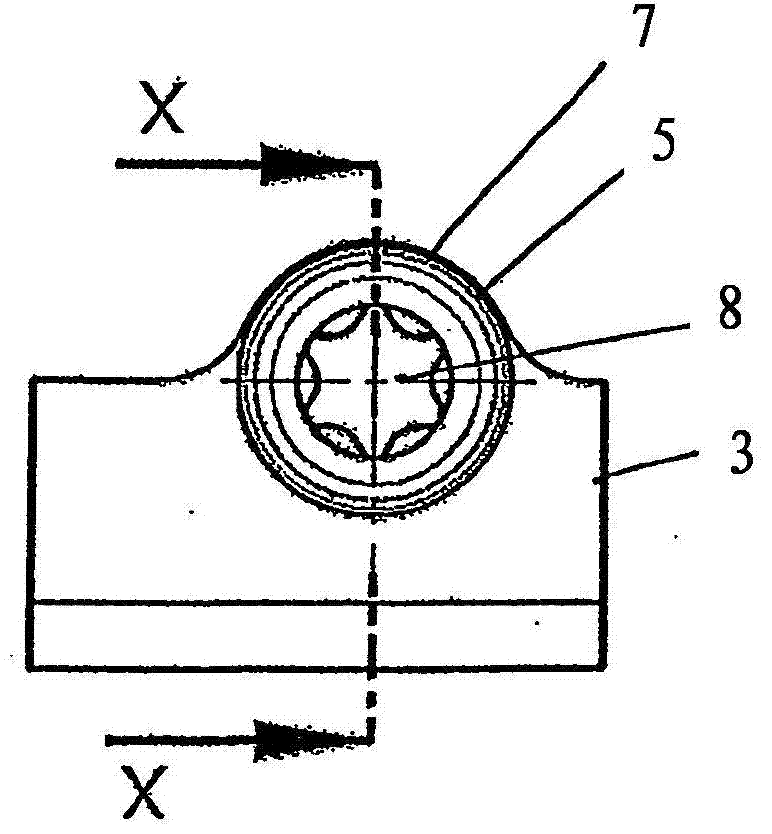

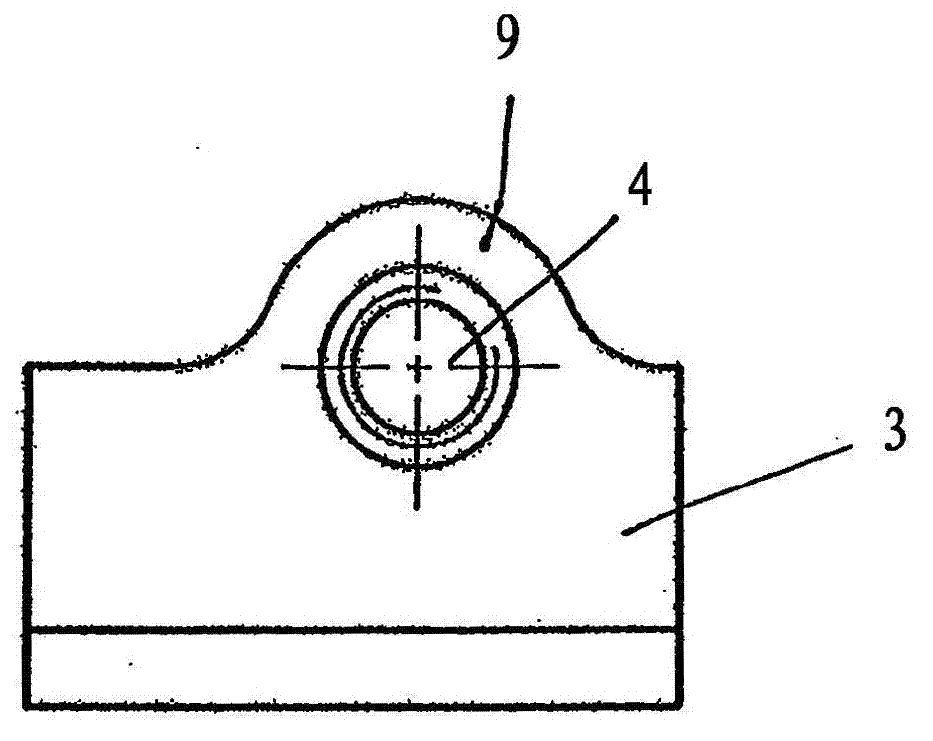

[0038]The oil sump 1 is essentially in the form of a cover-shaped channel with a surrounding fastening flange 3 and a plurality of perforations 4 , which pass through the fastening flange 3 at a distance from one another and are used for fastening screws 5 . The fastening screw 5 comprises a threaded shaft 6 with a preferably metric thread and a screw head 7 with a hexagonal recess 8 . exist Figures 1 to 3 In the shown exemplary embodiment of the housing cover according to the invention, only one of the perforations 4 shown is always provided in a fastening eye 9 integrally formed on the fastening flange 3 . The oil sump 1 abuts in a circumferential manner on a corresponding bearing surface (opposite surface) 10 of the gearbox hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com