On track maintainable low-power consumption high-reliability space brake

A technology of brakes and low power consumption, applied in the types of brakes, axial brakes, brake components, etc., can solve the problems of inability to achieve on-orbit maintenance, high power consumption, and low reliability, and achieve on-orbit debugging and reliability. The effect of maintenance, low power consumption, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

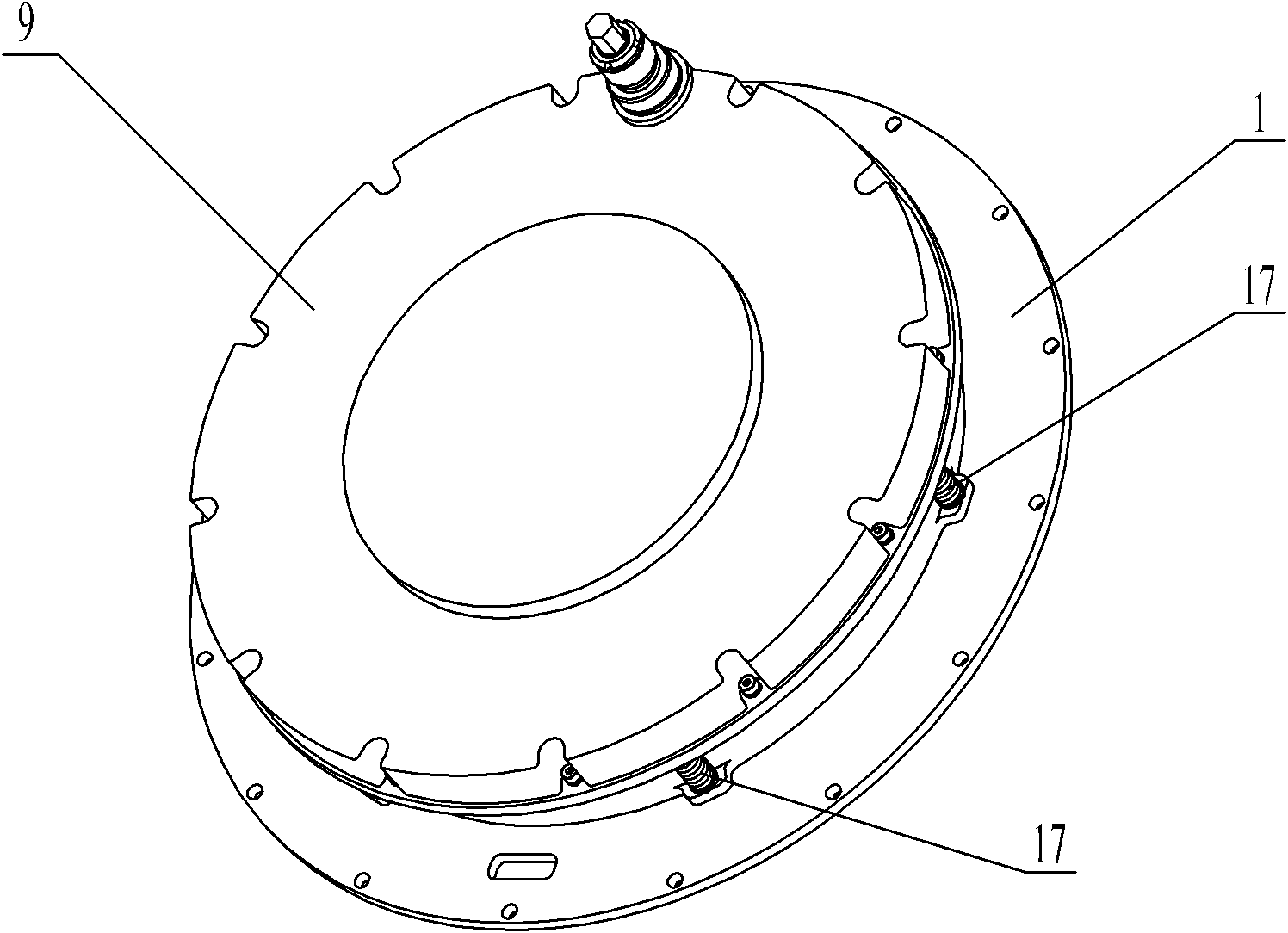

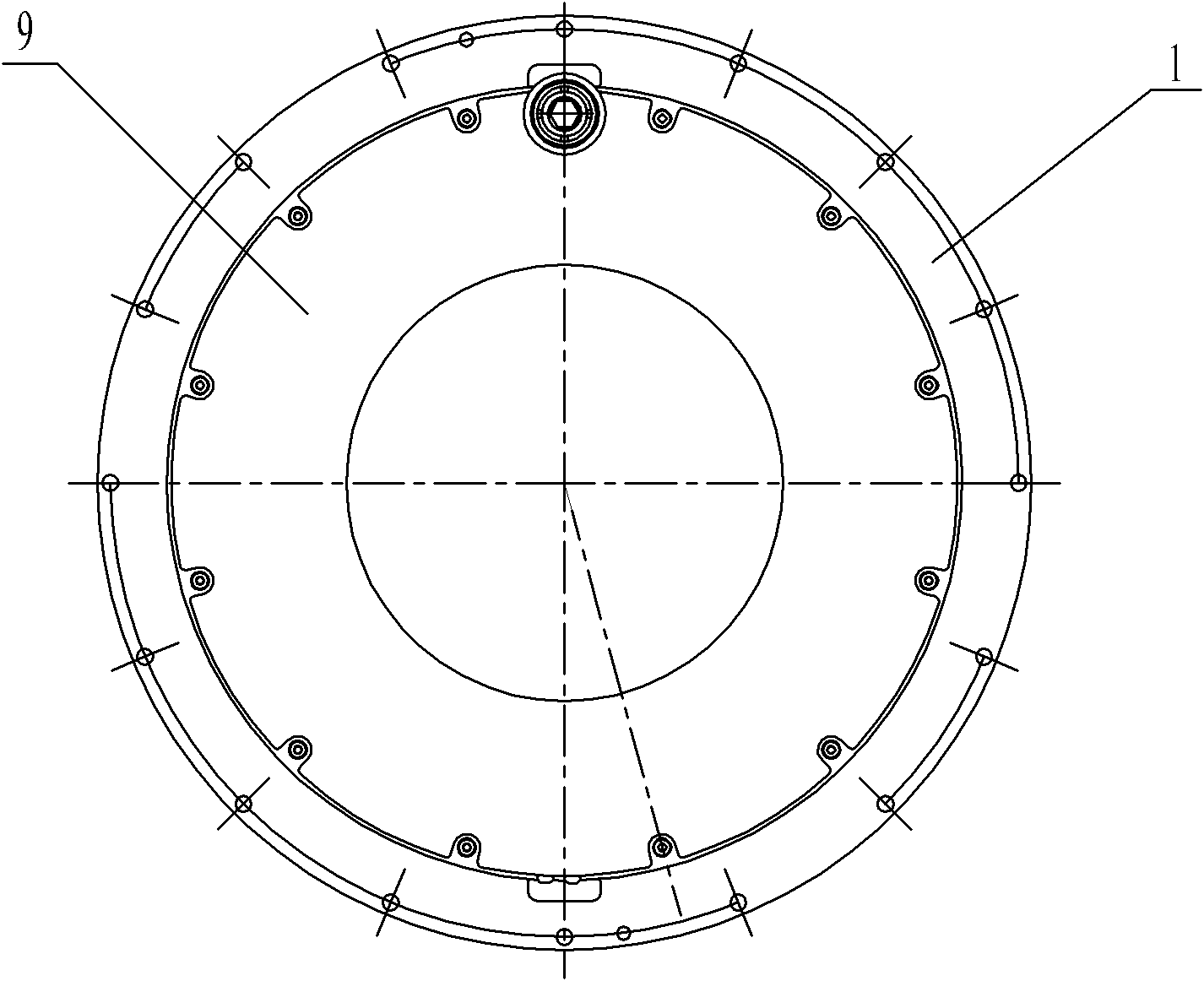

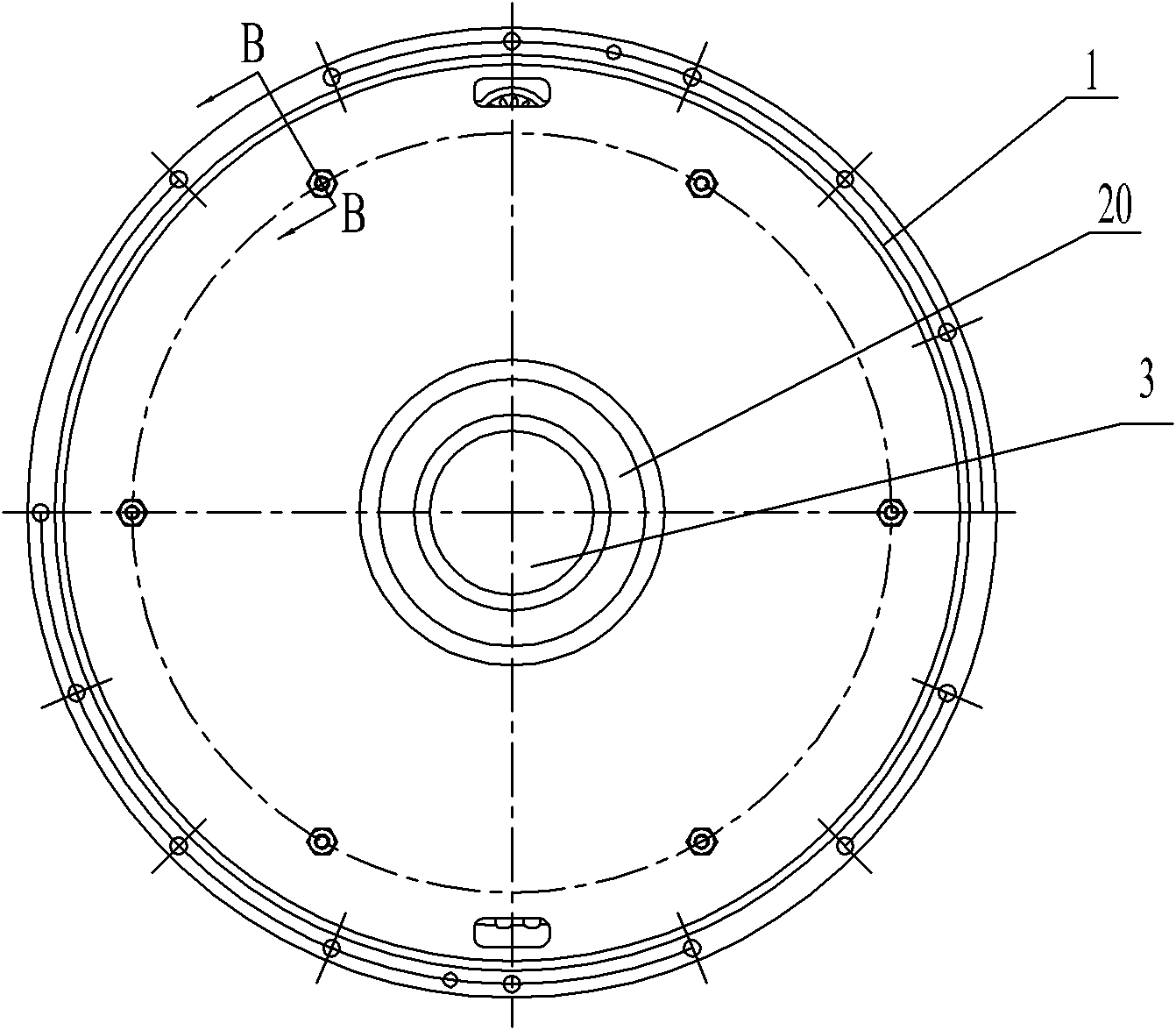

[0008] Specific implementation mode one: combine Figure 1-Figure 9 Describe this embodiment, the on-orbit maintainable low power consumption high reliability space brake of this embodiment includes a brake housing 1, a connecting shaft system 3 and a first bearing 20, and the brake housing 1 is sleeved on the connecting shaft system 3 A first bearing 20 is arranged between the brake housing 1 and the connecting shaft system 3; the on-rail maintainable space brake with low power consumption and high reliability also includes a double-winding redundant electromagnetic coil 2, an air gap adjustment sleeve 4, Armature friction disc 5, brake gear 6, brake cover 9, manual spring 10, spring gland 11, gear shaft 13, bearing gland 14, second bearing 15, multiple spring guide rods 16, multiple brake springs 17 and a plurality of first fastening nuts 19; an annular groove 1-1 is opened on the friction end surface of the brake housing 1, and the double-winding redundant electromagnetic c...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination Figure 4 and Figure 9 The present embodiment will be described. The diameter of the friction disc boss 5-1 in this embodiment is equal to the diameter of the gear boss 6-1. With such arrangement, the contact area is large, which better guarantees the reliability when the armature friction disc contacts with the large brake gear. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination Figure 4 and Figure 9 To describe this embodiment, the end surfaces of the friction disc boss 5-1 and the end surface of the gear boss 6-1 in this embodiment are both coated with a high wear-resistant ceramic coating. In this way, the high wear-resistant ceramic coating has the advantages of good thermal stability, large and stable friction coefficient and small wear. The characteristics of its thermal stability ensure that the brake has small deformation and stable mechanical properties in the vacuum high and low temperature environment of the space. The friction coefficient is large, so that the braking effect of the brake has obvious advantages compared with the brake of general materials. The stable friction coefficient ensures the stability of the braking torque and improves the stability and reliability of the brake in the space environment. The small amount of wear increases the brake's in-orbit service time an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com