Double-acting lockwasher

A gasket and support element technology, applied in the field of locking gaskets, can solve problems such as nut locking failure, and achieve the effect of improving fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

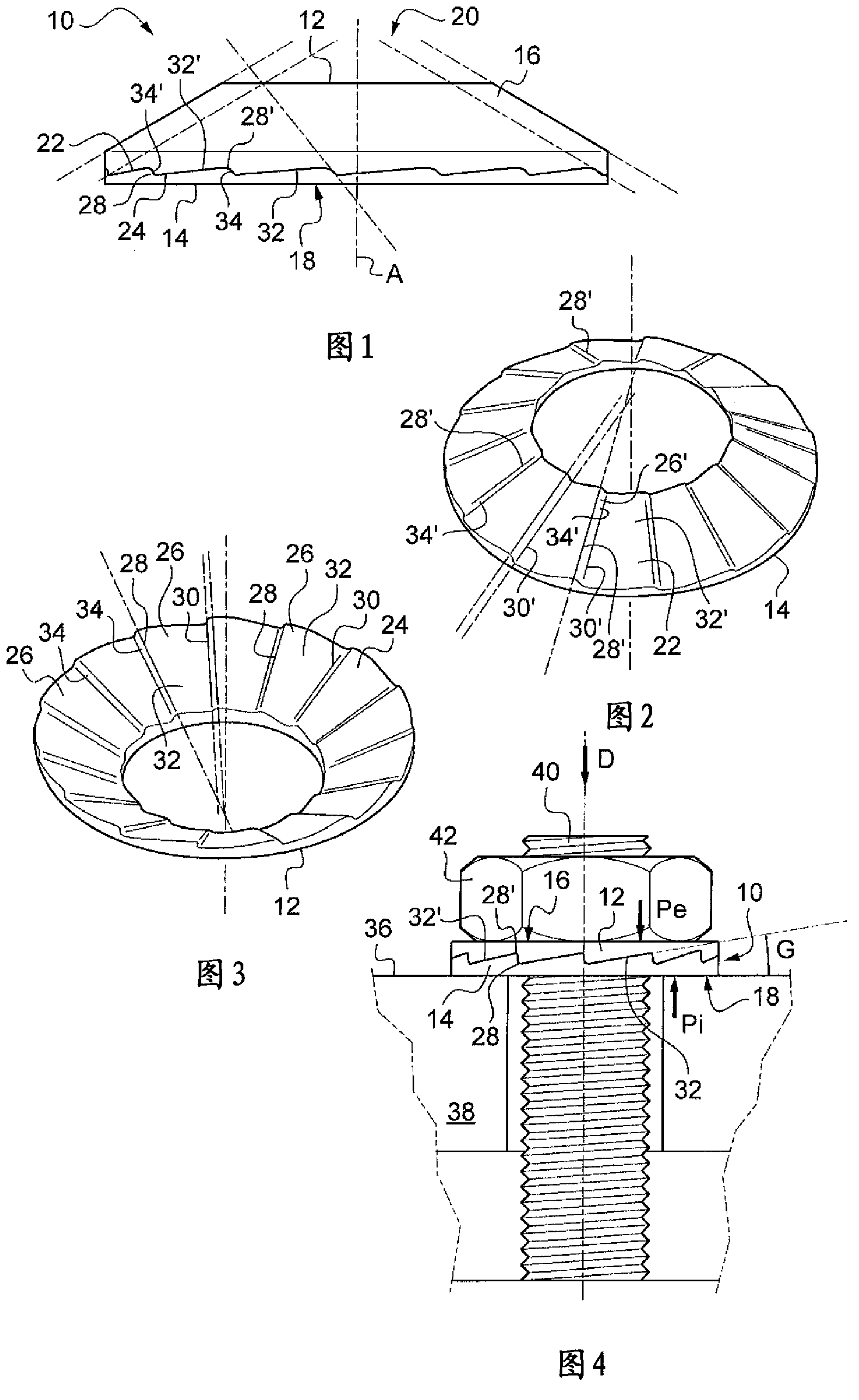

[0027] figure 1 A frustoconical locking washer 10 with an axis of symmetry A is shown in section. The figure shows the outer crown 12 and the inner crown 14 on the inside. The two rings 12, 14 engage each other and will be explained in detail below. Outer ring crown 12 has outer bearing journal 16 and infigure 1 The inner bearing journal 18 is shaded in the middle, while the locking washer 10 has a circular central hole 20 which can eg be engaged to a screw rod.

[0028] now refer to figure 2 , 3 . figure 2 represents a top perspective view of the inner crown 14, and figure 2 The outer ring crown 12 looking up appears. The outer crown 12 forms a first intermediate cone, while the inner crown 14 forms a second intermediate cone. The inner crown 14 has a convex joint surface 22 and the outer crown 12 has a concave joint surface 24 . The two joining surfaces 22 , 24 are complementary and can join each other, leaving no free space between the two rings 14 , 12 . The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com