Method of preventing surface of ultra-thin specification hot galvanized plate from being scratched

A technology of hot-dip galvanized sheet and specifications, applied in the direction of fusion spraying, metal material coating process, measuring device, etc., can solve problems such as surface scratches, and achieve the effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiment of the present invention solves the technical problem in the prior art that the surface of ultra-thin hot-dip galvanized products will be scratched by sinking rollers by providing a method for preventing the surface of ultra-thin hot-dip galvanized sheets from being scratched, and achieves improved The technical effect of the surface quality of ultra-thin gauge hot-dip galvanized products.

[0037] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows:

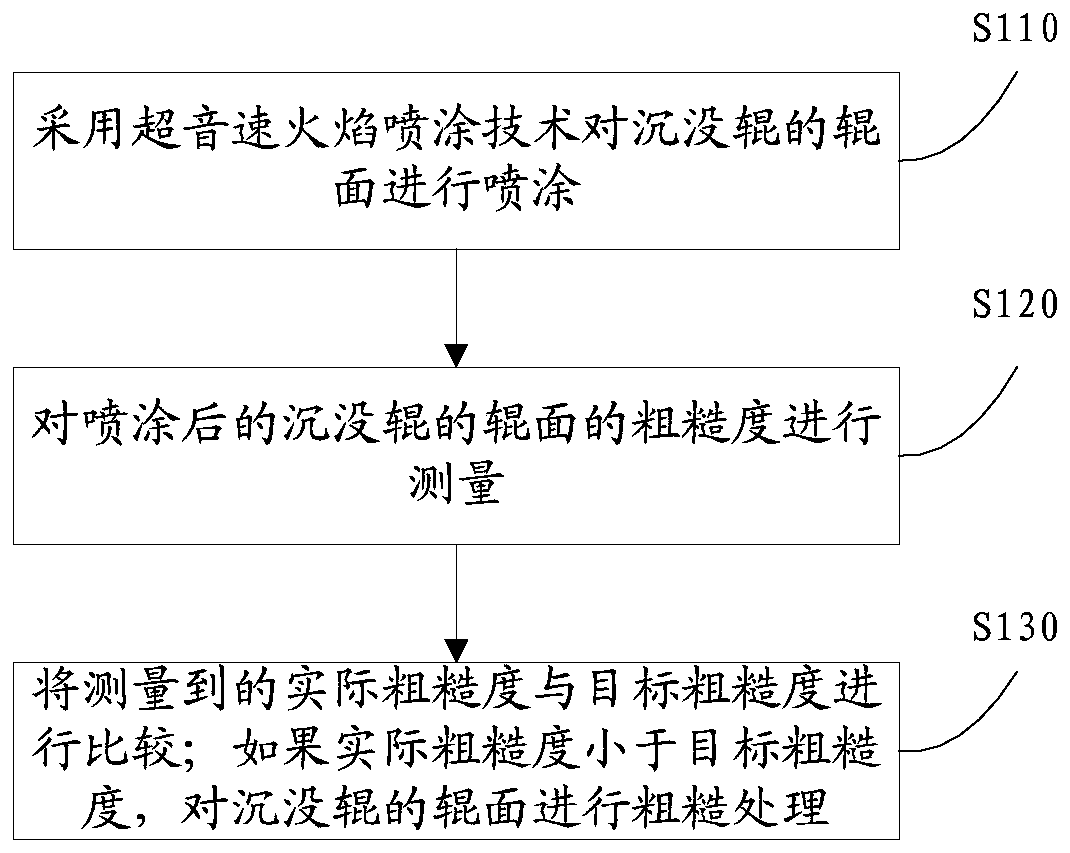

[0038] First use the supersonic flame spraying technology to spray the roller surface of the sinking roller; then measure the roughness of the roller surface of the sprayed sinking roller; then compare the measured actual roughness with the target roughness; if the actual roughness If the roughness is less than the target roughness, continue to roughen the surface of the sinking roller to ensure that the surface rough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com