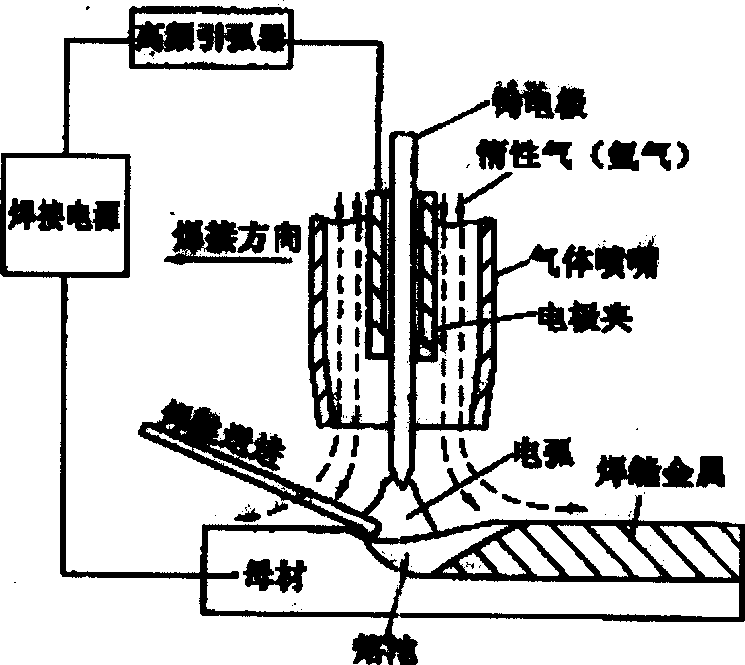

Dual tungsten electrodes welding torch in use for argon are welding

A tungsten argon arc and tungsten electrode technology, applied in arc welding equipment, electrode characteristics, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

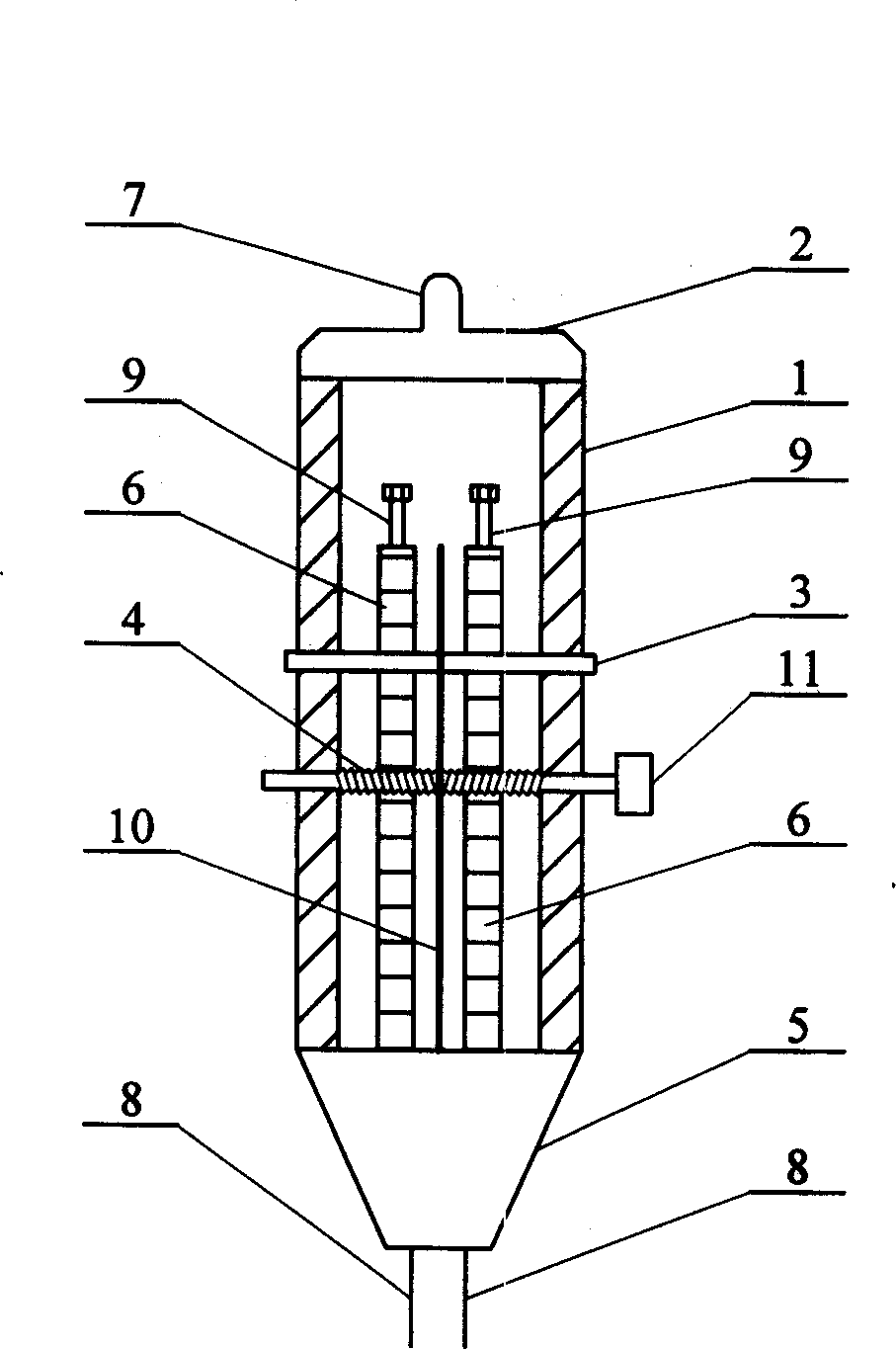

specific Embodiment approach 1

[0005] Specific implementation mode one: (see figure 2 ) This embodiment consists of a welding torch body 1, an air inlet cover 2, an air outlet cover 5, two conductors 6, two tungsten poles 8, two electric cable fastening bolts 9, and an insulating sheet 10; the air inlet cover 2 Fixed on the upper end of the torch body 1, the air inlet cover 2 is provided with an air inlet hole 7, the gas outlet cover 5 is fixed on the lower end of the torch body 1, and the upper ends of the two tungsten electrodes 8 are respectively fixed on the lower ends of the two conductors 6 , the two incoming cable fastening bolts 9 are respectively fixed on the upper ends of the two electric conductors 6, the two electric conductors 6 are arranged vertically and parallel in the torch body 1, and the lower ends of the two tungsten electrodes 8 are arranged at the lower end of the gas outlet cover 5 The insulating sheet 10 is arranged between the two conductors 6 in the torch body 1 .

specific Embodiment approach 2

[0006] Specific implementation mode two: (see figure 2 ) The difference between this embodiment and the specific embodiment one is that it increases the guide rod 3 and the distance adjustment screw 4, the guide rod 3 and the distance adjustment screw 4 are vertically arranged with the conductor 6 respectively, and the middle part of the guide rod 3 is arranged In the two conductors 6 and insulating sheet 10, the guide rod 3 is slidingly connected with the conductor 6, the two ends of the guide rod 3 are fixed on the outer wall of the welding torch body 1, and the middle part of the adjustable distance screw 4 is arranged on the conductor 6. And in the insulating sheet 10, the two ends of the distance-adjusting screw 4 are arranged on the outer wall of the welding torch body 1 on the lower side of the guide rod 3, and one side end of the distance-adjusting screw 4 is provided with a knob 11, and the distance-adjusting screw The bar 4 is threadedly connected with the two condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com