Rotary swing type welding torch and welding method

A welding torch and contact tip technology, applied in the field of welding and narrow gap welding, can solve problems such as poor fusion of groove side walls, and achieve the effects of solving poor fusion, enhancing reliability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Aiming at the problems existing in the welding process of large-thickness plates, the first aspect of the present invention provides a rotary-type welding torch, which can successfully perform narrow-gap welding of large-thickness plates.

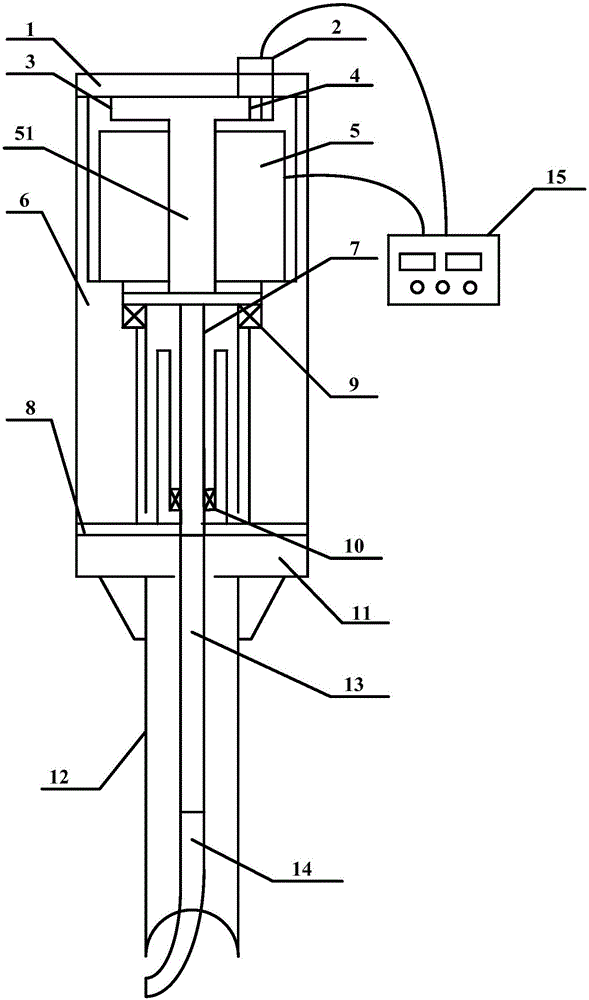

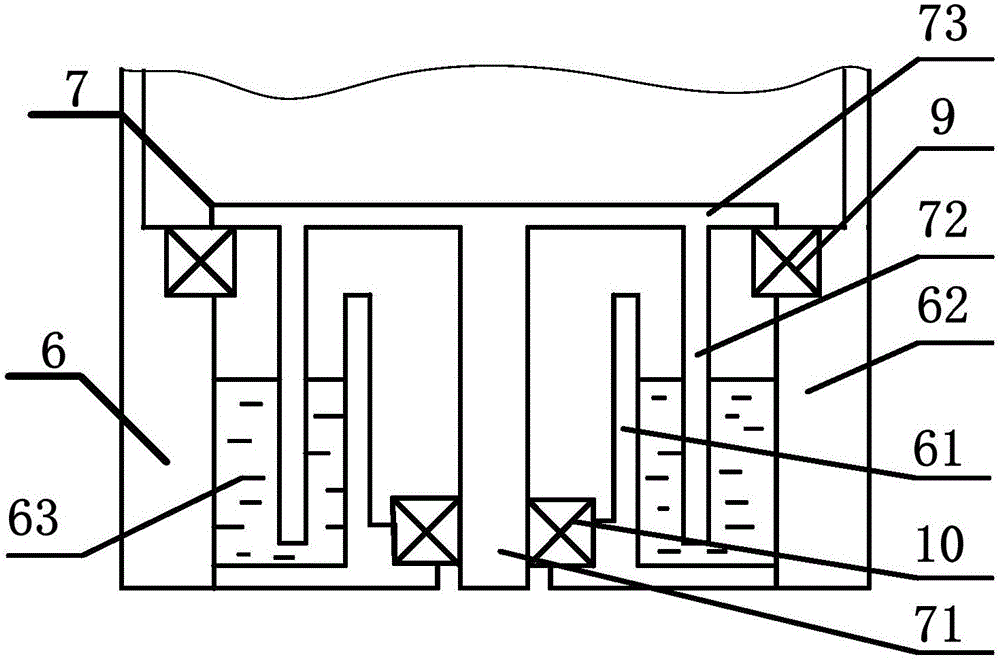

[0027] Such as figure 1 As shown, a rotary torch of the present invention includes a contact tip 14 , a rotary drive mechanism, and a control device 15 . Wherein, the control device 15 is connected with the swing drive mechanism to control the movement of the swing drive mechanism, and the movement output end of the swing drive mechanism is connected with the contact tip 14, so that Under the control of the control device 15 , the position of the contact tip 14 is adjusted and / or the contact tip 14 is made to perform a swing motion according to preset swing parameters, that is, a rotation motion and / or a swing motion. In the present invention, the swing parameters preferably include swing angle, swing frequency and residence time, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com