Aluminum alloy laser welding method

A laser welding, aluminum alloy technology, applied in laser welding equipment, welding equipment, cleaning methods and utensils, etc., can solve the problem of increasing the size of the keyhole, increasing the size of the molten pool and heat input, and aggravating the burning loss of the low melting point alloy elements of the aluminum alloy. and other problems to achieve the effect of improving the strength of the joint and overcoming the increase in heat input

Inactive Publication Date: 2019-07-26

JIANGSU JICUI ADVANCED METAL MATERIAL RES INST CO LTD

View PDF14 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] However, due to the complexity of the operation of the above-mentioned existing welding methods, on the one hand, it increases the equipment cost and the complexity of the process; and the improvement of the mechanical properties of the joints, and it will also increase the burning loss of low melting point alloy elements such as magnesium and zinc during the aluminum alloy welding process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

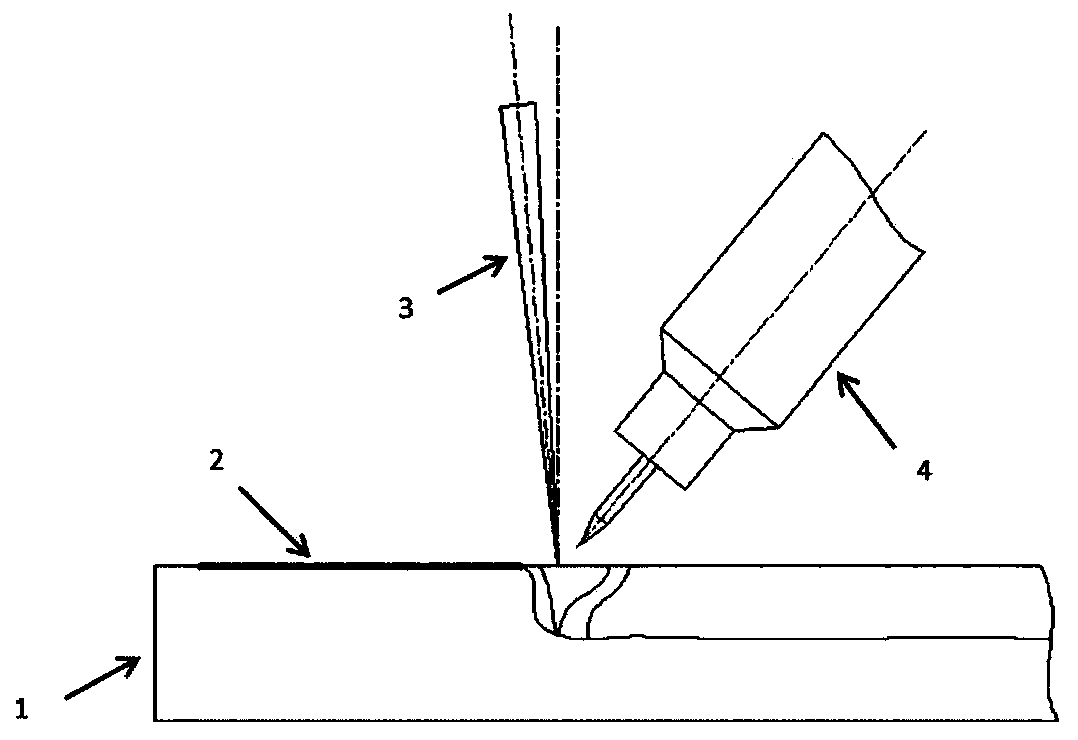

[0030] Embodiment: the angle between the axis of the laser head and the vertical direction is α=5°, and the angle between the axis of the laser head and the vertical direction is β=40°;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

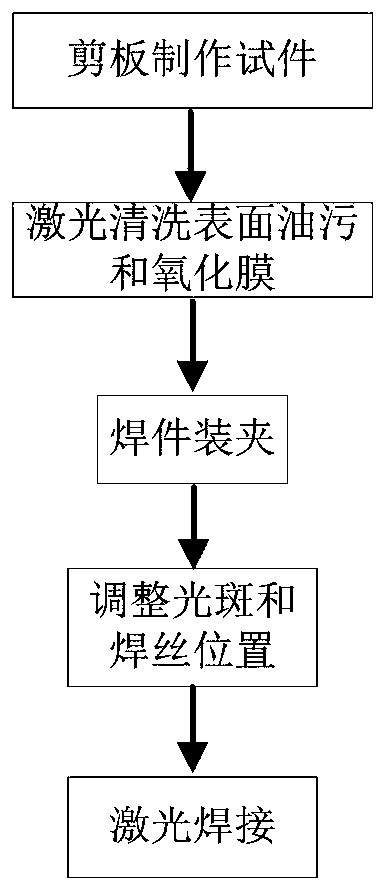

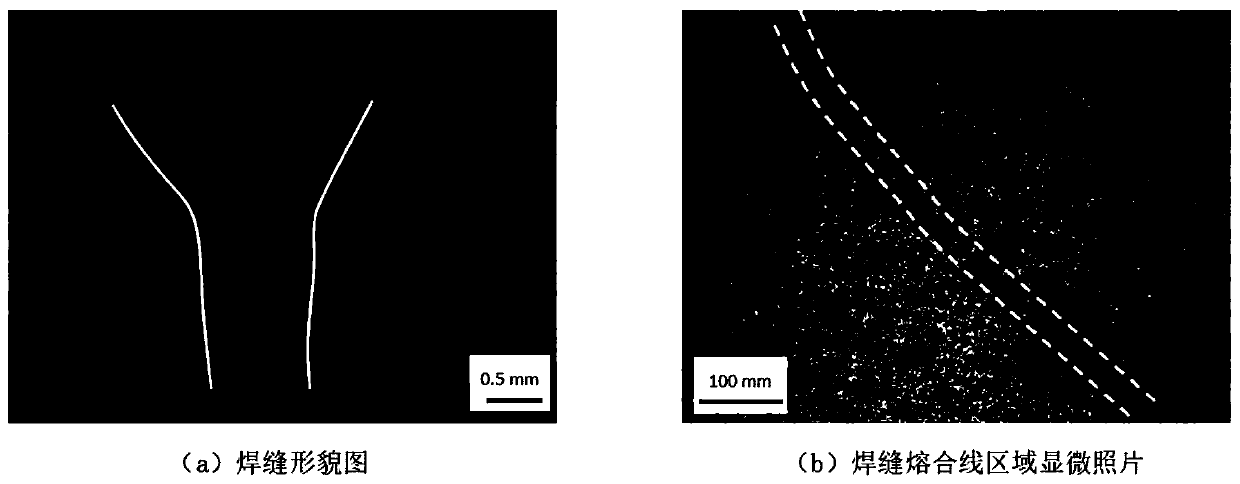

The invention discloses an aluminum alloy laser welding method. The aluminum alloy laser welding method is used for carrying out aluminum alloy laser welding under the specific laser head angle, wirefeeding angle and specific spot welding wire molten pool position relation, the stability of a molten pool and the timely liquid metal supplement of process air holes during the collapse of key holesare guaranteed, so that the generation of the process air holes is effectively controlled, and meanwhile, the heat input increase caused by the fact that the size of the key holes is added to maintainthe stability of the molten pool is overcome, the deformation is increased, the burning loss of the alloy element is intensified, and the strength of a joint is effectively improved.

Description

technical field [0001] The invention relates to the technical field of advanced welding of lightweight aluminum alloys, in particular to the technical field of laser wire-filled welding of aluminum alloys. Background technique [0002] Due to its high specific strength, good corrosion resistance, easy forming, and good regeneration performance, aluminum alloys are widely used in automobile manufacturing, aerospace, new energy power batteries and other industries. The selection of aluminum alloy materials is an effective way to achieve lightweight. The laser welding technology has the advantages of high efficiency and small heat-affected zone. In developed countries such as Japan and Germany, the laser welding technology of aluminum alloys has been used in automobile manufacturing, aerospace and other fields. With the continuous maturity of aluminum alloy laser welding technology, This technology is gradually used in shipbuilding, new energy power batteries and other fields. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K26/24B23K26/12B23K26/70B08B7/00B08B3/12B23K103/10

CPCB08B3/12B08B7/0042B23K26/123B23K26/24B23K26/702B23K2103/10

Inventor 薛志清赵锐李乡亮

Owner JIANGSU JICUI ADVANCED METAL MATERIAL RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com