Laser scanning path planning method used for additive-manufacturing three-dimensional object

A laser scanning path, three-dimensional object technology, applied in the field of additive manufacturing, can solve problems such as low forming quality, achieve high energy, ensure forming quality, and improve the effect of heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

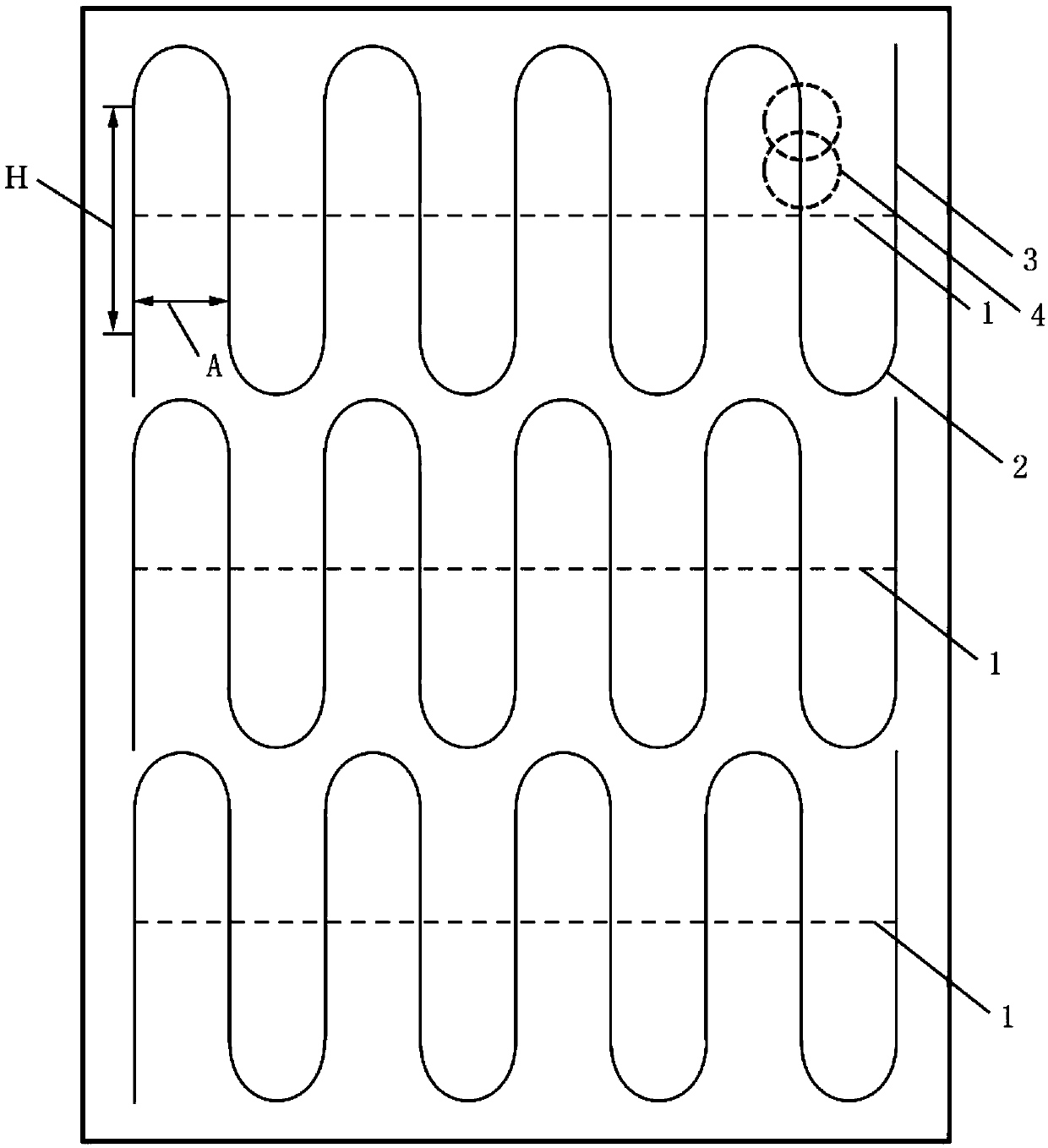

[0026] A laser scanning path planning method for additively manufacturing three-dimensional objects of the present invention, the specific operation process includes the following steps, such as figure 2 Shown:

[0027] Step 1. Input the slice files of each layer of the part model;

[0028] Step 2. Determine the partition reference line according to the structural characteristics of the part and user settings, and partition the slices of each layer of the part;

[0029] The specific process of step 2 is as follows:

[0030] Step 2.1 Read in the height H of the straight line segment 3 in the serpentine path set by the user, the radius R of the arc segment 2, the scanning distance A and the diameter D of the spot 4; among them,

[0031] Step 2.2 Determine the position of the reference line 1 of each partition according to the structural c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com