Thermoelement

a technology of thermoelement and temperature data, applied in the field of thermoelement, can solve the problems of inaccurate temperature data and inaccuracy in measuring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

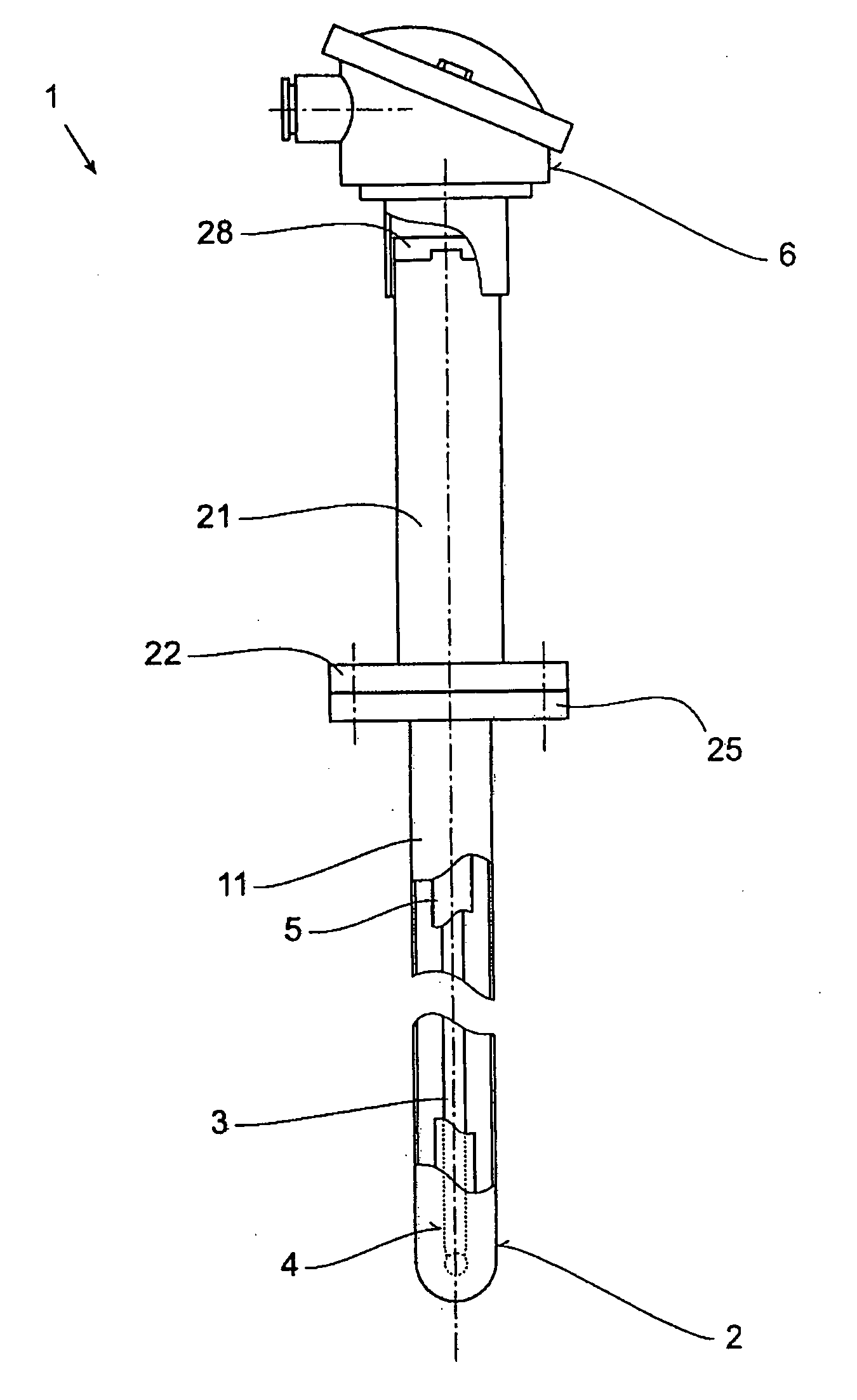

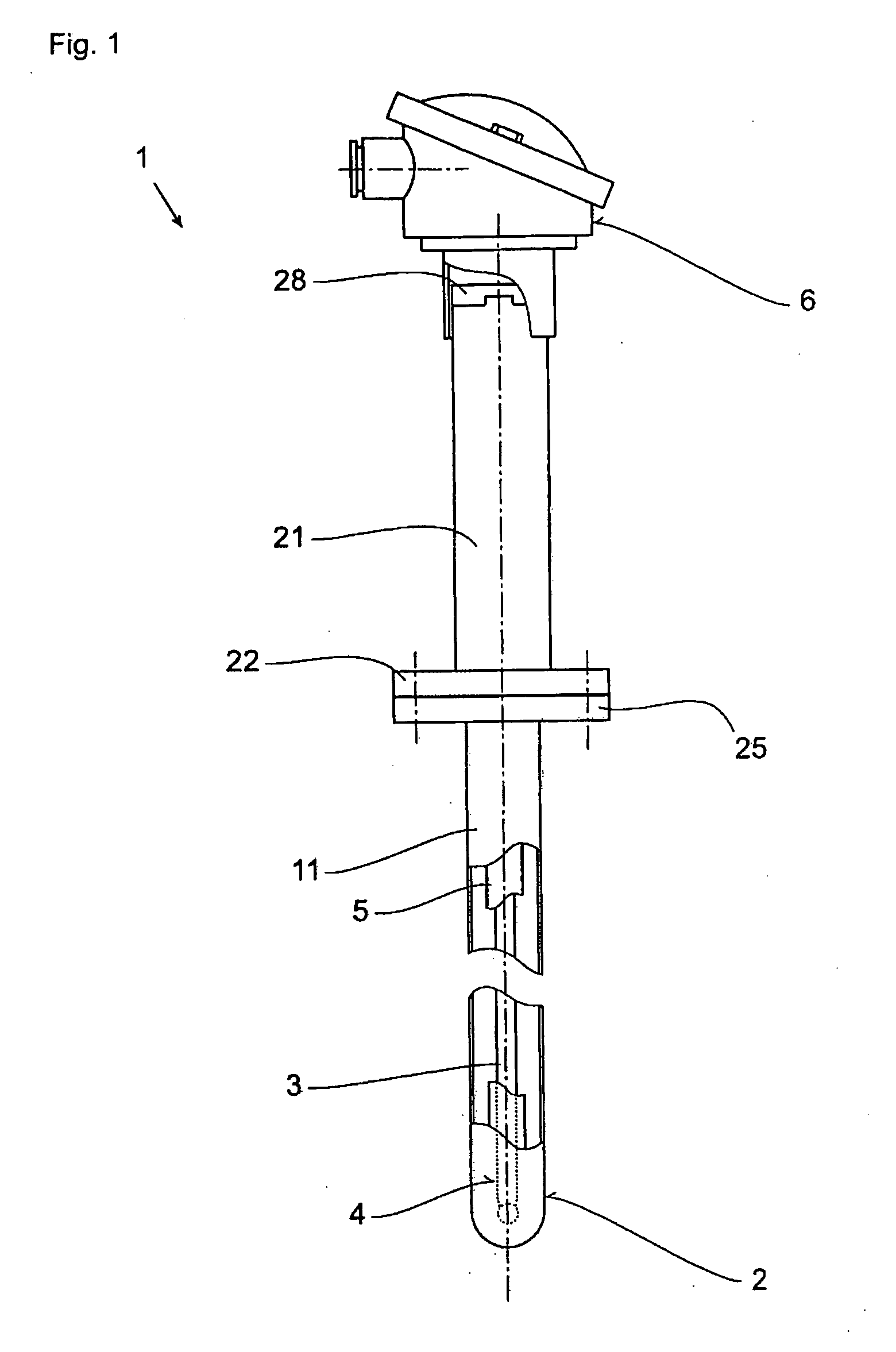

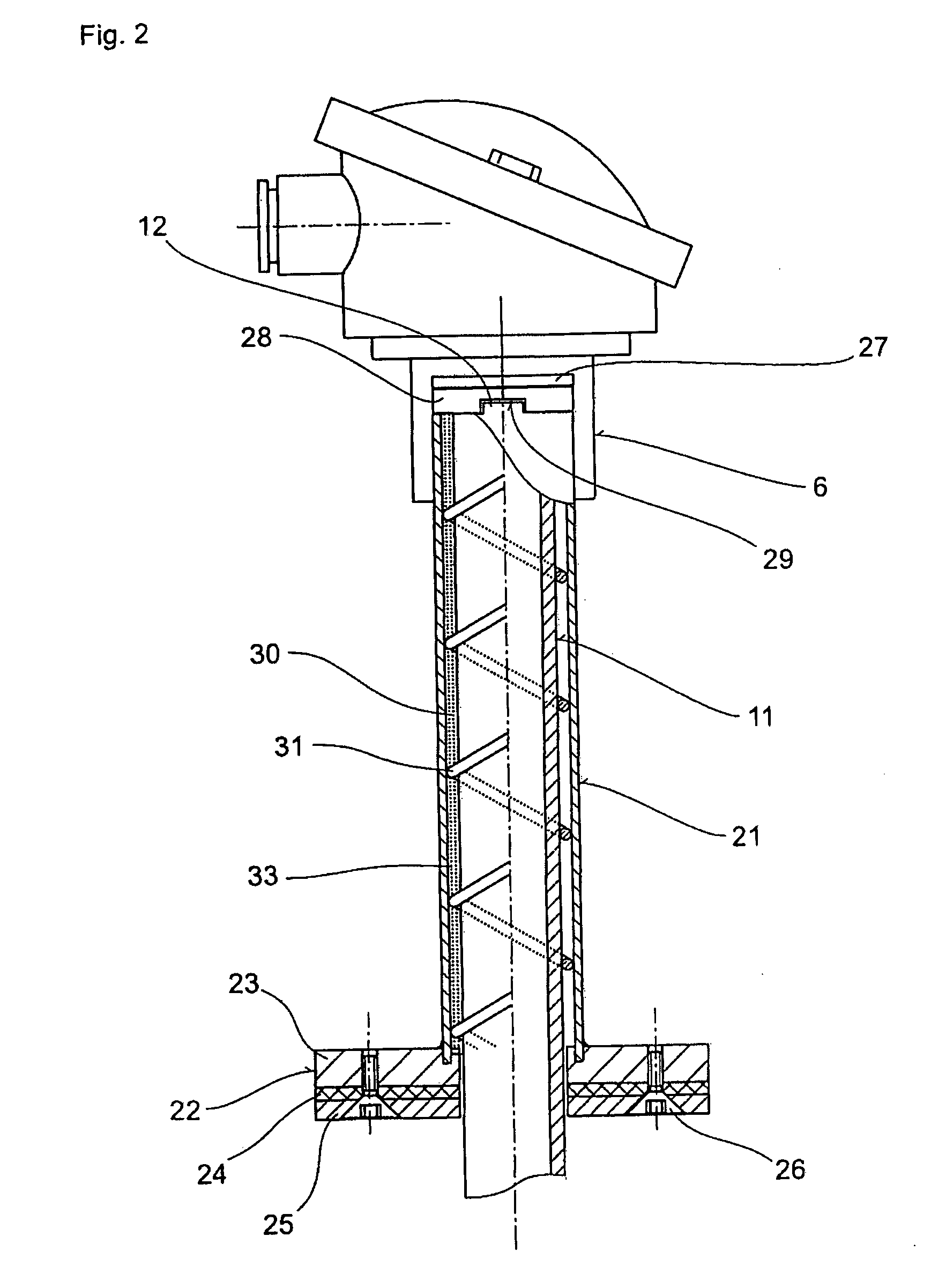

[0019]The thermoelement 1 shown in FIG. 1 is used for measuring temperatures in gaseous or fluid media in thermal process systems and has a measuring insert 2 that is attached to a connection head 6 and is surrounded by a protective tube 11 and a holding tube 21. The measuring insert 2 comprises an insulating rod 3, and inner tube 5 and thermocouples 4 comprising wires made from different kinds of metals welded together.

[0020]In order to avoid a high level of heat input into the connection head 6, the holding tube 21 is arranged with a radial distance from the protective tube 11, with the result that an air gap 30 is formed between them. A trace 31 made from a heat-resistant or ceramic material arranged in a helical profile in the air gap is wrapped around the protective tube 11 and is glued onto it and / or the holding tube 21, and the trace 31 supports the holding tube 21 on the protective tube 11. The air gap in this case acts as a thermal insulator. If necessary, insulating materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| electrical voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com