Resistance welding method, resistance welding equipment and method for manufacturing electronic component

A technology of resistance welding and electronic components, applied in the direction of resistance welding equipment, welding equipment, welding power supply, etc., can solve the problems of increased manufacturing cost, perforation of plate metal parts 12, and insufficient bonding strength, so as to reduce manufacturing cost and prevent processing The effect of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

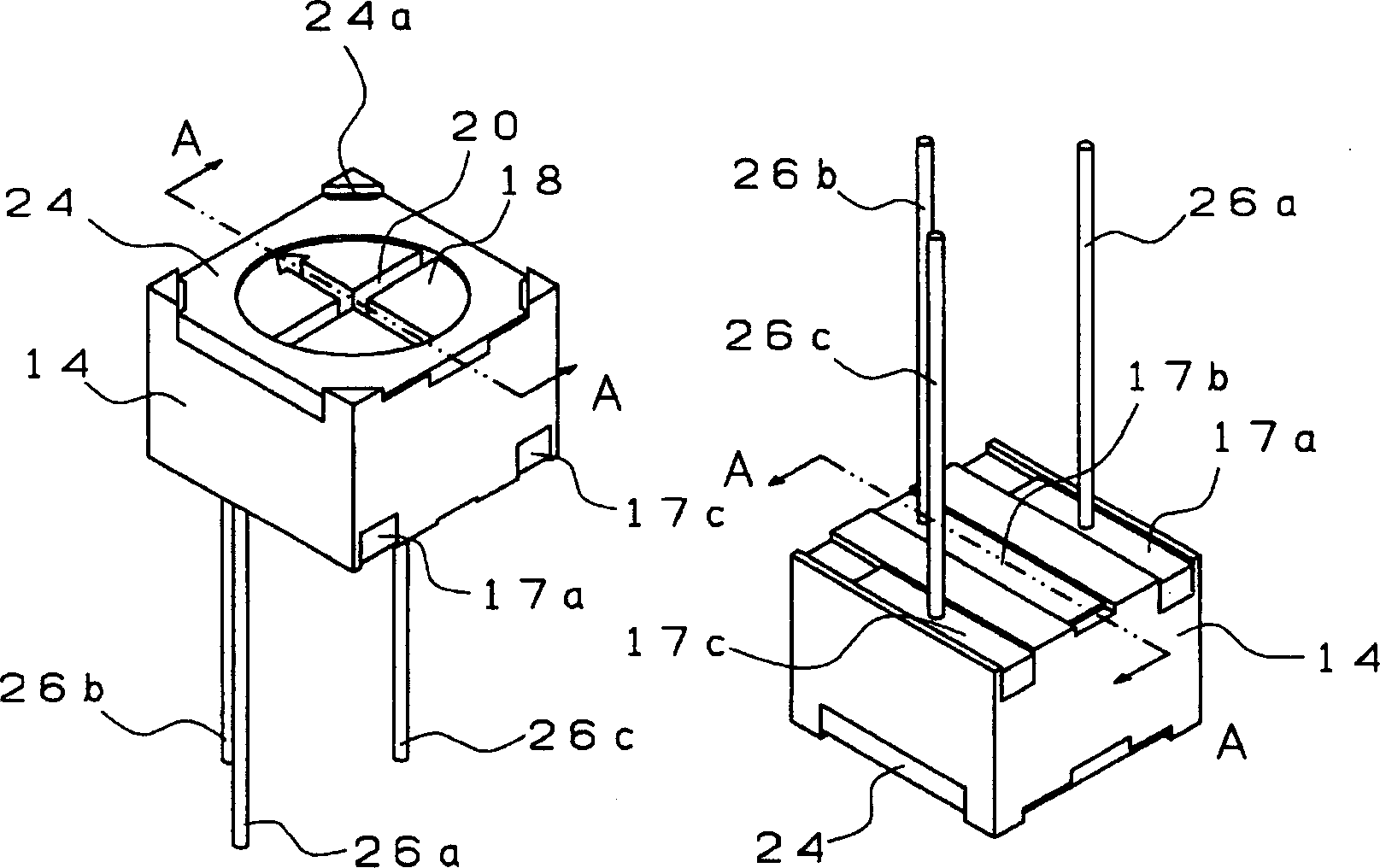

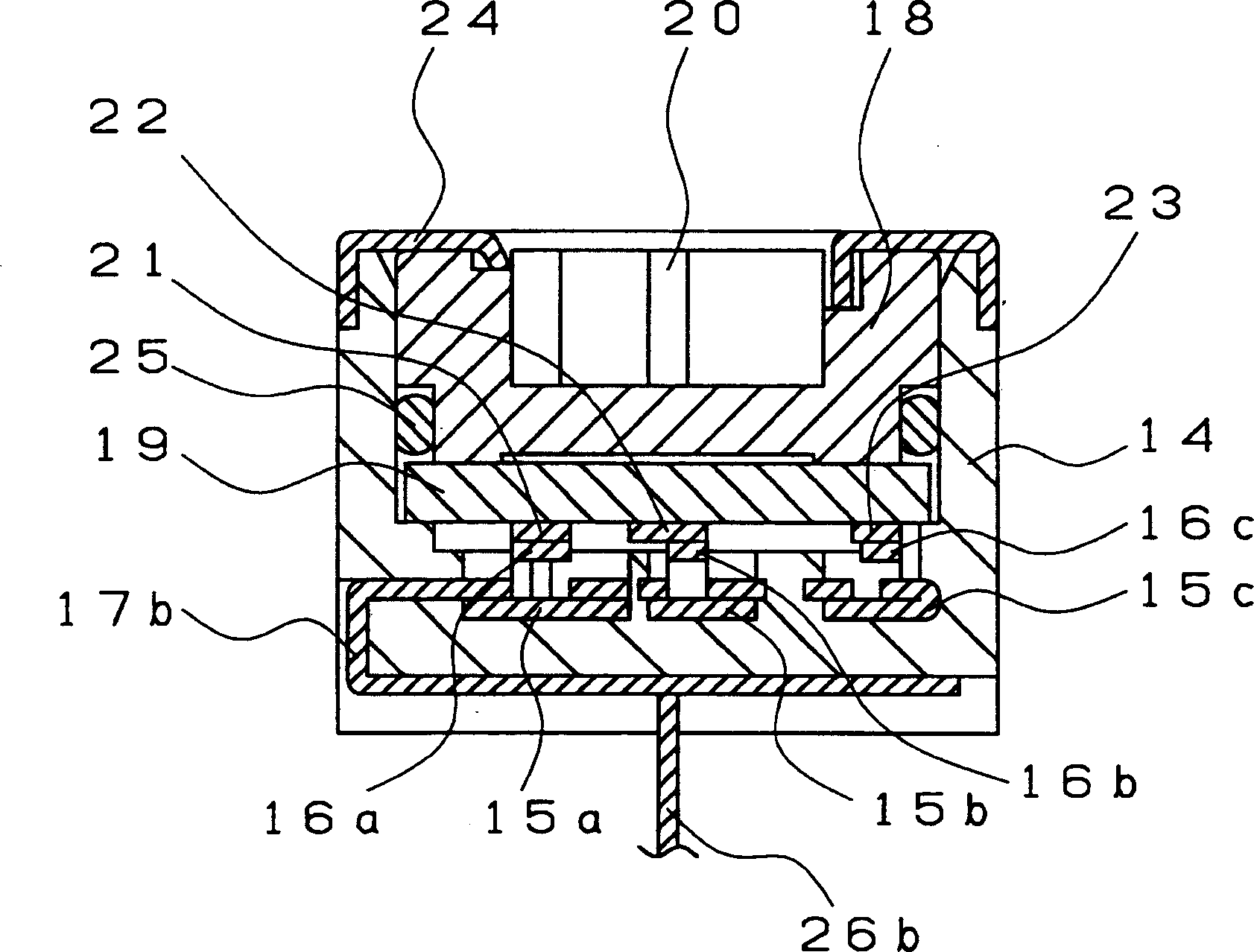

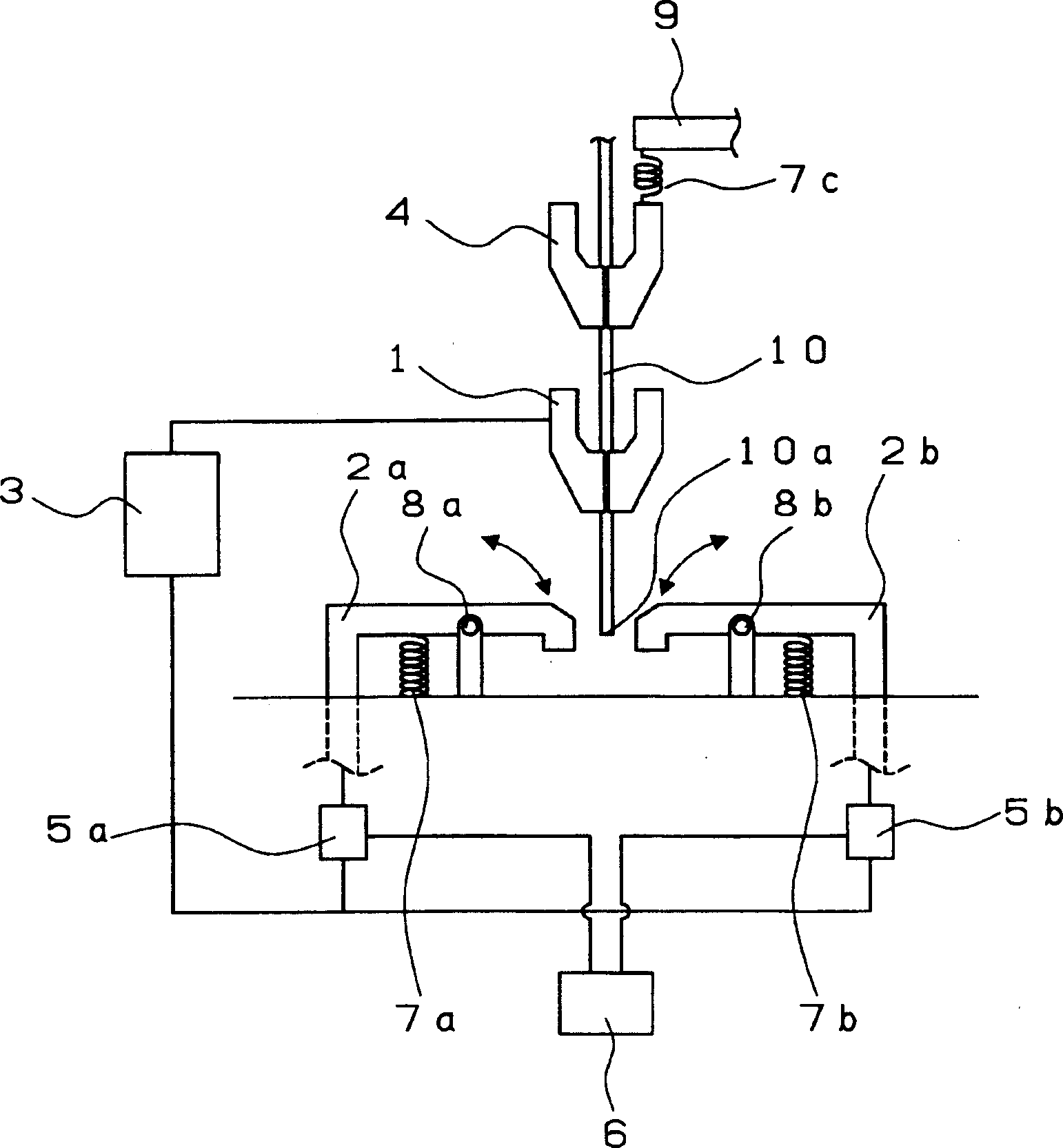

[0031] The structure of a variable resistor as an example of an electronic component used as a workpiece in a preferred embodiment of the present invention will be described with reference to FIGS. 1 and 2 . 1A and 1B are perspective views of variable resistors. figure 2 It is a sectional view of the variable resistor along line A-A in Fig. 1.

[0032] Such as figure 2 As shown, the variable resistor includes a housing 14, sliding contacts 15a, 15b, and 15c, a rotor, a metal cover 24, and lead terminals 26a, 26b, and 26c (wherein, the lead terminals 26a and 26c are shown in FIG. figure 2 not shown).

[0033] Housing 14 made of heat resistant resin or other suitable material includes recesses, sliding contacts 15a, 15b and 15c are bent upwards and their respective ends define arms 16a, 16b and 16c. Also, the sliding contacts 15a, 15b, and 15c are connected to external electrodes 17b, 17a, and 17c, respectively. Furthermore, the rotor is arranged in a recess in the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com