Artificial joint material

A technology for artificial joints and joints, used in medical science, tissue regeneration, prostheses, etc., can solve the problems of unsatisfactory level, insufficient strength of porous titanium materials, affecting strength properties, etc., to improve long-term stability and good biological phase. Capacitance, the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

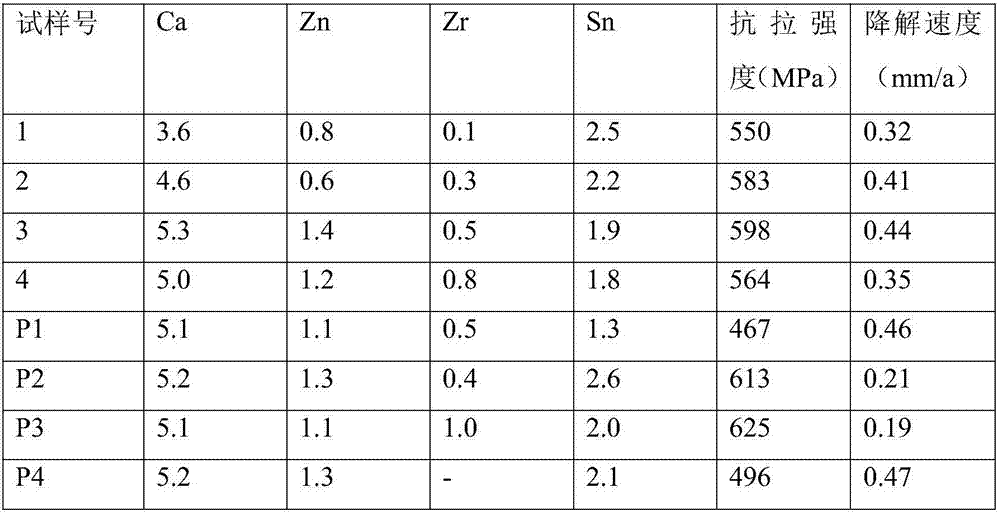

[0020] First, the titanium alloy used in the present invention was prepared, and its composition and strength obtained by testing are shown in Table 1.

[0021] Table 1 List of titanium alloy components

[0022] Sample No. Al V Cu Nd Tensile strength (MPa) 1 5.1 3.8 5.4 0.8 1065 2 5.0 4.1 4.5 1.1 1153 3 5.0 3.9 4.1 0.5 1078 4 5.1 4.0 3.2 0.3 1027 P1 5.0 4.1 6 0.7 985 P2 5.1 3.9 3.5 0.1 958 P3 5.1 4.0 - - 910

[0023] It can be seen that the tensile strength of the titanium alloy of the present invention exceeds that of Ti-6Al-4V. It is worth noting tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com