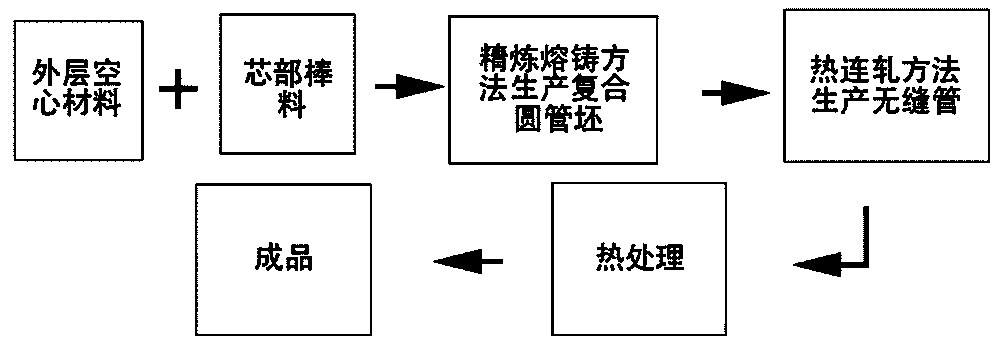

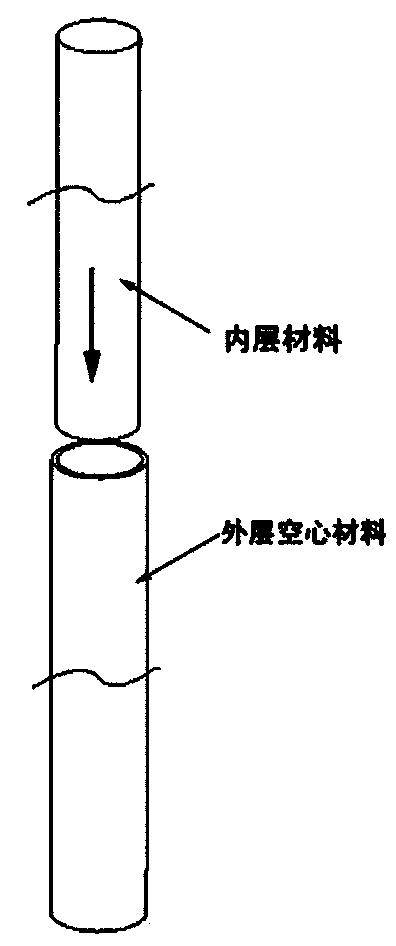

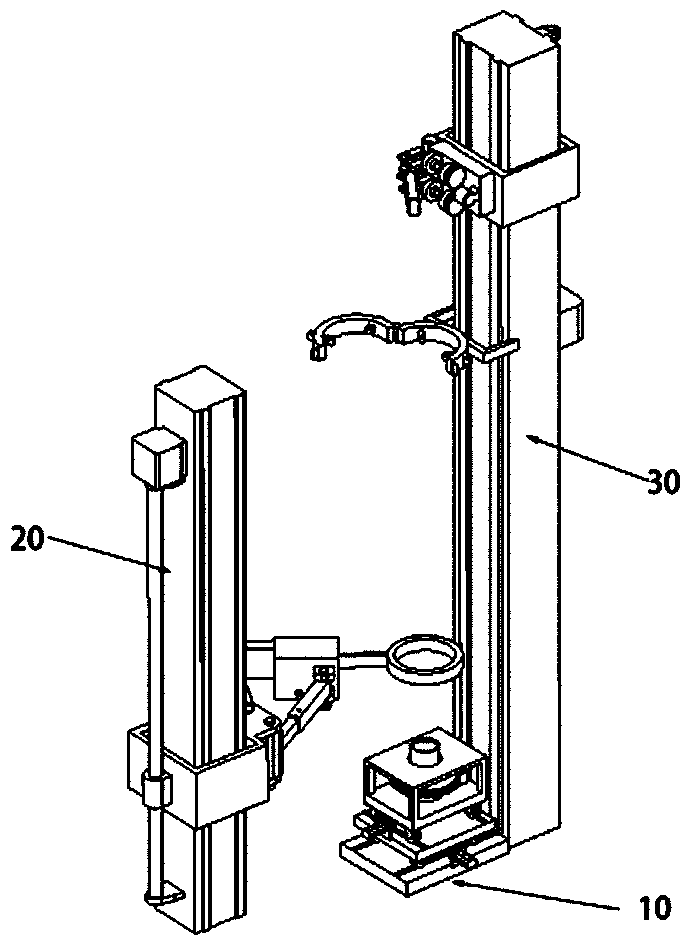

Bi-metal metallurgical bonding composite seamless pipe blank production process and device

A technology of metallurgical combination and production process, which is applied in the field of bimetallic metallurgy combined seamless pipe blank production process and its device, can solve the problems of uneven wall thickness of two layers of metal, complicated process, low yield of finished products, etc., and achieve saving Heavy metal materials, solve the interface delamination, the effect of uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The base pipe is 10#, 20# and other carbon steel, bonded steel and other carbon steel, and its preheating temperature is 850°C. The inner layer is compounded with 13Cr, 304, 316, OCr25N120, lneone1600 and other corrosion-resistant materials or nickel-based alloys. It is mainly used for fluid and gas pipelines where the inner wall has corrosion resistance requirements and the outer wall has higher requirements for strength.

Embodiment 2

[0078] The base pipe is Cr5-Cr12 heat-strength steel and heat-resistant steel, and its preheating temperature is 900°C; the inner layer is composited with corrosion-resistant stainless steel or alloy. It is mainly used for fluid and gas pipelines with high corrosion resistance requirements on the inner wall and low corrosion requirements on the outer wall, and certain thermal strength requirements.

Embodiment 3

[0080] The base layer of the wear-resistant pipe is 16Mn, and its preheating temperature is 950°C; the inner layer is compounded with 70Mn2. It is mainly used in pulverized coal, ash removal and slag removal pipelines in power plants: mine tailings filling, tailings storage, concentrate transportation, washing plants, and other high-wear working environments such as gasoline.

[0081] In addition, it can also produce multi-layer composite steel pipes with corrosion-resistant stainless steel inside and outside, composite steel and carbon steel in the middle, or multi-layer composite steel pipes with composite steel and carbon steel inside and outside, and corrosion-resistant stainless steel in the middle; It is required to produce metallurgical composite double-layer metal seamless pipes in various use environments. (The thickness of the inner layer is 1 / 3-1 / 2 of the total thickness, and composite seamless pipes of various specifications and thicknesses can also be produced acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com