Curable organic polysiloxane composition and application thereof

A technology of polysiloxane and composition, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems that light-emitting diodes cannot reflect light, and achieve improved anti-vulcanization effect, prevent phosphor powder from settling, and effectively silver layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

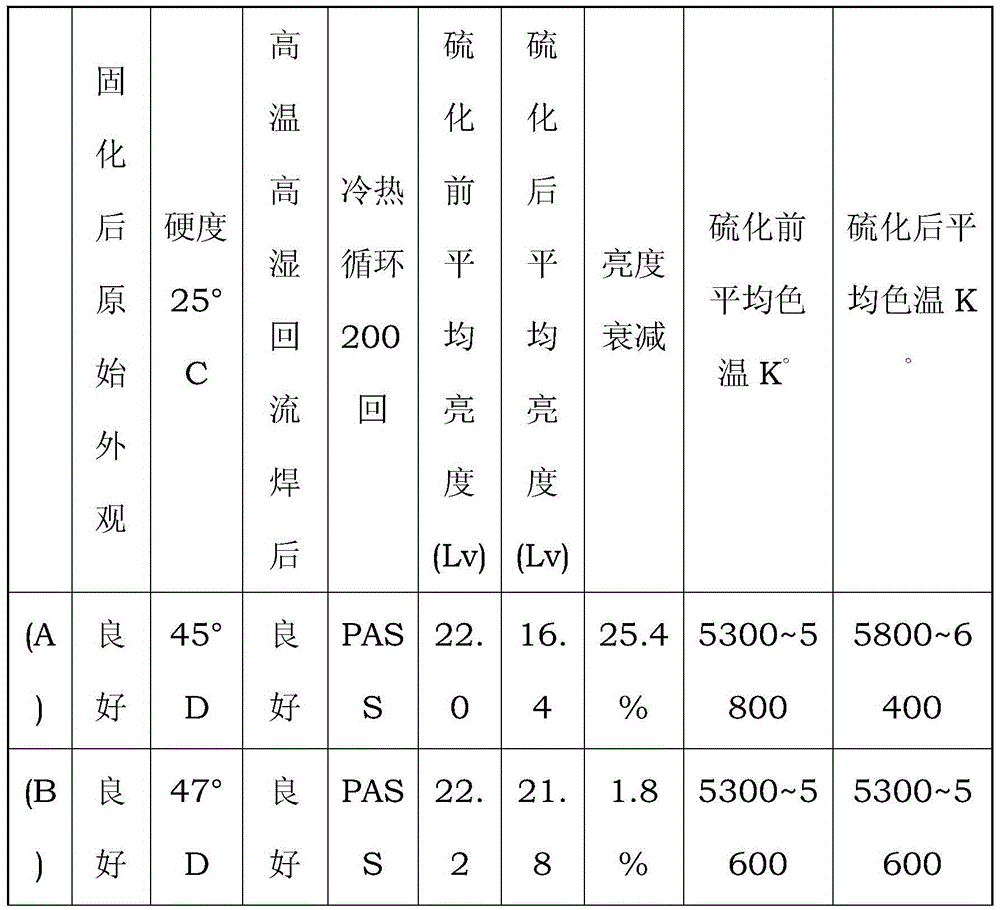

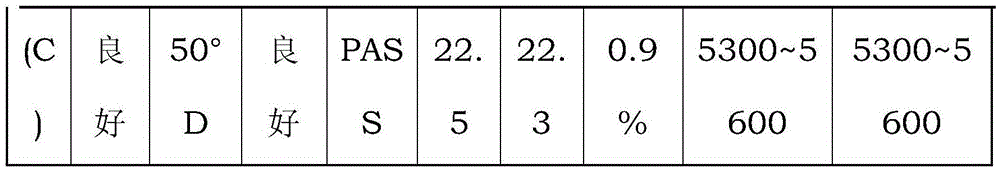

Embodiment 1

[0022] The polymethylphenyl silicone resin polymer containing silicon-bonded vinyl group and the polymethylphenyl silicone resin polymer containing silicon-bonded hydrogen group are uniformly mixed. Among them, the silicon-bonded vinyl content is 4.5 wt%, the silicon-bonded hydrogen group content is 0.13 wt%, and the silicon-bonded phenyl content is 49 wt%. A platinum complex compound of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane is used as a catalyst. (Platinum accounts for 3ppm of the total structure weight) and 1-ethynyl cyclohexanol is used as a working time regulator. (accounting for the total structure weight 150ppm) After the above ingredients are fully and uniformly mixed, the viscosity is 3500cps at 25°C. Divide this thing evenly into three parts, namely (A)(B)(C).

[0023] (A) as a blank test;

[0024] (B) mixed with wt3% magnesium hydroxide (Sigma-Aldrichcompany U.S.A reagent grade, purity 95%);

[0025] (C) mixing the above-mentioned magnesium hydroxide of wt5%;...

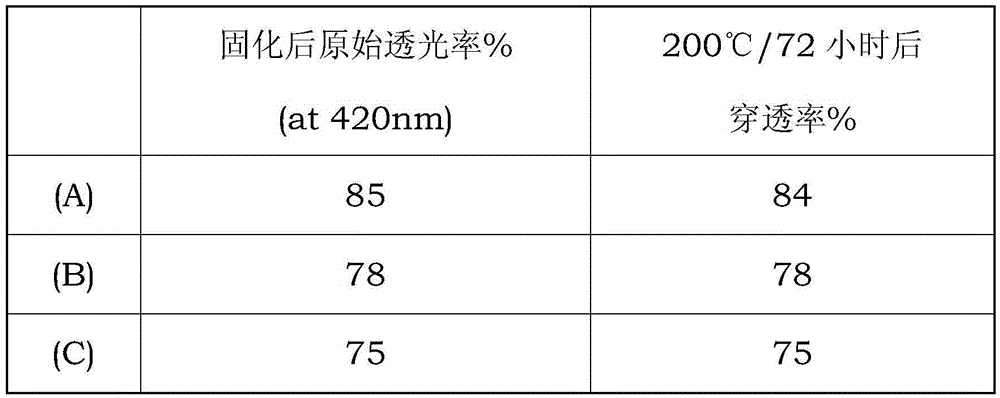

Embodiment 2

[0036] The polymethylphenyl silicone resin polymer containing silicon-bonded vinyl groups and the polymethylphenyl silicone resin polymer containing silicon-bonded hydrogen groups are mixed together. Among them, the silicon-bonded vinyl content is 4.7wt%, the silicon-bonded hydrogen group content is 0.14wt%, and the silicon-bonded phenyl group content is 49wt%. A platinum complex compound of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane is used as a catalyst. (Platinum accounts for 3ppm of the total structure weight) and 1-ethynyl cyclohexanol is used as a working time regulator. (accounting for the total structure weight 150ppm) After the above ingredients are fully and uniformly mixed, the viscosity is 3500cps at 25°C. Divide this thing evenly into three parts, namely (A)(B)(C).

[0037] (A) As a blank test

[0038] (B) Mixed with 5% wt of magnesium oxide (Sigma-Aldrichcompany U.S.A reagent grade, specific surface area 130㎡ / g, particle size<25 μm (XRD)).

[0039] (C) 5% by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com