Copper alloy wire and manufacturing method thereof

A technology of copper alloy wire and manufacturing method, which is applied in the field of bonding wire, can solve problems such as poor anti-aging performance and high temperature and high humidity resistance, lack of market competitiveness, and complicated manufacturing process, so as to improve gold ball shedding, excellent Good workability and anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

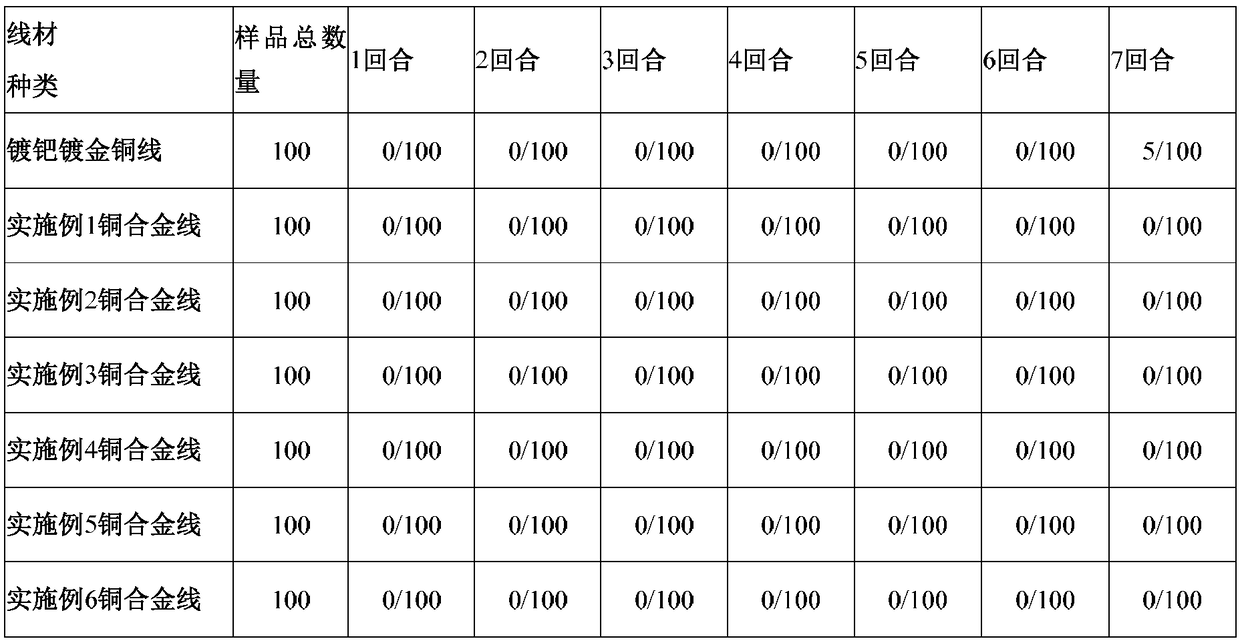

Embodiment 1

[0031] The copper alloy wire of this embodiment contains 1.2% by weight of Ag, 200ppm of Ca, 200ppm of In, 300ppm of Ge, and the balance is copper.

[0032] The manufacturing method of above-mentioned copper alloy wire comprises the following steps:

[0033] (1) Melting and casting: adding Ag, Ca, In and Ge to the copper raw material in proportion, through vacuum smelting and directional continuous casting process, a wire rod with a diameter of 6 mm is obtained;

[0034] (2) wire drawing: the wire rod obtained in step (1) is drawn to obtain a copper alloy wire with a diameter of 200um;

[0035] (3) Intermediate annealing: After step (2) wire drawing is completed, intermediate annealing is carried out to the copper alloy wire, and N is used in the annealing process. 2 As the annealing atmosphere, the effective length of the annealing furnace is 900mm, the annealing temperature is 400°C, and the annealing rate is 60m / min;

[0036] (4) Continue to draw the copper alloy wire thr...

Embodiment 2

[0040] The copper alloy wire of this embodiment contains Ag 0.1%, Be 300ppm, In 300ppm, Ge 400ppm by weight, and the balance is copper.

[0041] The manufacturing method of above-mentioned copper alloy wire comprises the following steps:

[0042] (1) Melting and casting: Ag, Be, In and Ge are added to the copper raw material in proportion, and through vacuum melting and directional continuous casting process, a wire rod with a diameter of 6 mm is obtained;

[0043] (2) wire drawing: wire rod obtained in step (1) is drawn to obtain a copper alloy wire with a diameter of 180um;

[0044] (3) Intermediate annealing: After step (2) wire drawing is completed, intermediate annealing is performed on the copper alloy wire. During the annealing process, nitrogen-hydrogen mixed gas is used as the annealing atmosphere. The effective length of the annealing furnace is 800mm, and the annealing temperature is 500°C. The annealing rate is 100m / min;

[0045] (4) Continue to draw the copper a...

Embodiment 3

[0050] The copper alloy wire of this embodiment contains 2.5% by weight of Ag, 400ppm of Ca, 400ppm of Ge, and the balance is copper.

[0051] The manufacturing method of above-mentioned copper alloy wire comprises the following steps:

[0052] (1) Melting and casting: adding Ag, Ca and Ge to the copper raw material in proportion, through vacuum smelting and directional continuous casting process, a wire rod with a diameter of 8 mm is obtained;

[0053] (2) wire drawing: wire rod obtained in step (1) is drawn to obtain a copper alloy wire with a diameter of 250um;

[0054] (3) Intermediate annealing: After step (2) wire drawing is completed, intermediate annealing is carried out to the copper alloy wire, and N is used in the annealing process. 2 As the annealing atmosphere, the effective length of the annealing furnace is 800mm, the annealing temperature is 600°C, and the annealing rate is 80m / min;

[0055] (4) Continue to draw the copper alloy wire through the intermediate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com