Anti-aging waterproof structure convenient for construction

A waterproof structure and anti-aging technology, which is applied in building components, sea area engineering, water conservancy engineering, etc., can solve the problems of poor polyurea or polyurethane effect, achieve the effect of small thickness, easy cutting, and improved bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

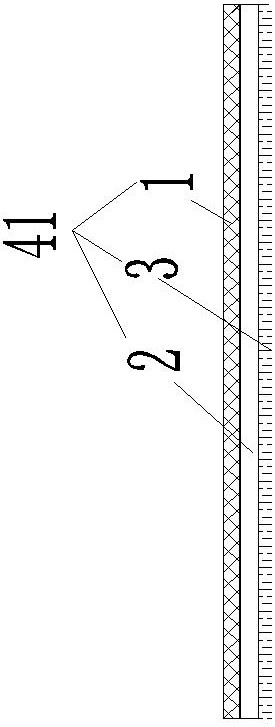

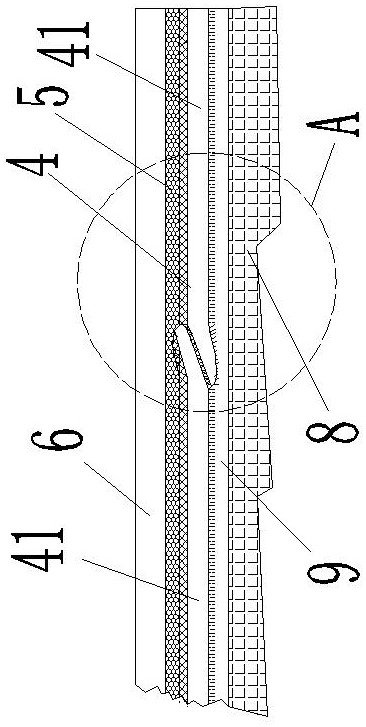

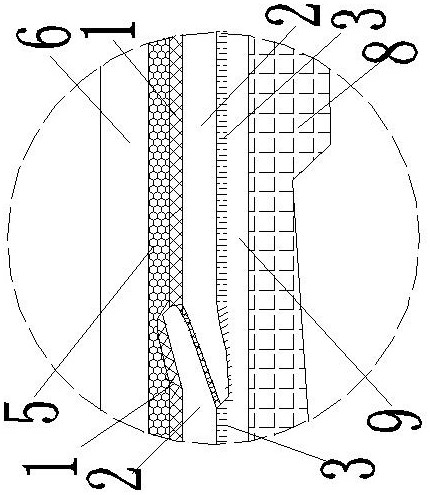

[0063] Example 1. Such as Figure 1-3As shown, an aging-resistant waterproof structure that is convenient for construction includes a spraying auxiliary layer 4 formed by overlapping and connecting several spraying auxiliary coils 41; Bonding; the top surface of the spraying auxiliary layer 4 is sprayed or coated with a polyurethane layer 5, and the top surface of the polyurethane layer 5 is sprayed with a polyurea protective layer 6; the bottom surface of the spraying auxiliary layer 4 is made of cement-based adhesive or cement slurry The adhesive layer 9 is bonded with the region 8 to be constructed;

[0064] The spraying auxiliary coil 41 includes a 0.5mm polyvinyl chloride soft layer 2, a polypropylene non-woven fabric 1 with a mesh structure that is hot-compressed and laminated on the top surface of the polyvinyl chloride soft layer 2, and hot-pressed and laminated on the polyvinyl chloride soft layer 2. The bottom surface of layer 2 bottom surface is the polyester clot...

Embodiment 2

[0090] Example 2. The difference between this embodiment and embodiment 1 is that the polypropylene non-woven fabric 1 is 40g / m 2 Polypropylene spunbond nonwoven fabric. The thickness of the polyvinyl chloride soft layer 2 is 0.9 mm.

[0091] The polyester cloth 3 is a polyester filament hot-rolled non-woven fabric.

[0092] The polyester cloth 3 is a polyester filament hot-rolled non-woven fabric of 70g / m 2 Polyester filament hot-rolled non-woven fabric.

[0093] The raw material of the polyvinyl chloride soft layer 2 includes the following components and parts by weight: 100 parts of polyvinyl chloride resin, 30 parts of diisononyl phthalate, 2 parts of DOTP softening plasticizer, 2 parts of OPE lubricant, 11 parts of dioctyl oxalate, 2 parts of epoxidized soybean oil, 1.5 parts of antimony trioxide, 0.10 parts of sodium pentachlorophenate, 0.05 parts of pentaerythritol β-dodecylthiopropionate, liquid barium-zinc composite stabilizer 1-2 parts of agent, 5 parts of chlor...

Embodiment 3

[0114] Example 3. The difference between this embodiment and embodiment 2 is: as Figure 4-6 As shown, one side of the bottom surface of the polyvinyl chloride soft layer 2 is left with a lower lap area 21 without polyester cloth 3, and the side of the top surface of the base layer away from the lower lap area is left with a polypropylene non-woven fabric. The upper lap area 22 of the cloth 1. The spraying auxiliary coil material includes a 0.9mm polyvinyl chloride soft layer 2, a polypropylene non-woven fabric with a mesh structure 1 that is hot-pressed and laminated on the top surface of the polyvinyl chloride soft layer 2, and hot-pressed and laminated on the polyvinyl chloride soft layer. 2. The bottom surface of the bottom surface is polyester cloth 3 with a rough surface.

[0115] Polypropylene non-woven fabric 1 is 50g / m 2 Polypropylene spunbond nonwoven fabric.

[0116] The polyester cloth 3 is a polyester filament hot-rolled non-woven fabric.

[0117] The polyest...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com