Horizontal well oil-string casing well cementation method

A technology of horizontal well and casing, which is applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc. It can solve the problems of high cost and low quality of casing cementing in horizontal well oil layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

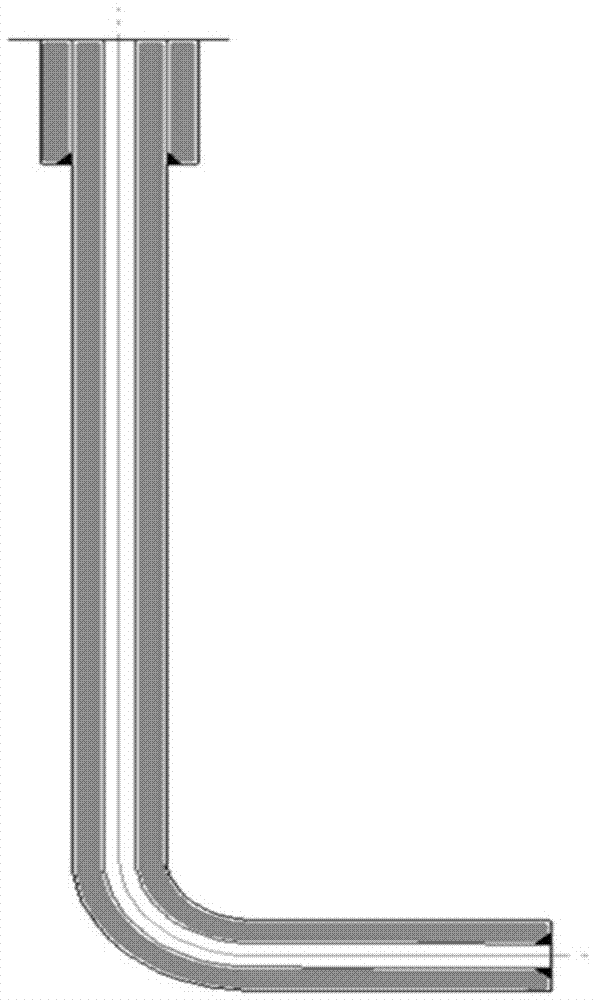

[0057] Take a horizontal well in Honghe Oilfield of North China Branch Company as an example. The well is a two-dimensional horizontal well. The basic situation of the actual drilling is as follows: firstly, a Ф311.2mm drill bit was used to drill to 303m, and a Ф244.5mm surface casing was run to 302.91m , to carry out surface casing cementing; the second opening was drilled with a Ф215.9mm drill bit to 3149m, and the horizontal section was 911.80m long. It is planned to run an oil layer casing with an outer diameter of Ф139.7mm, steel grade N80, and a wall thickness of 7.72mm ( The schematic diagram of the actual drilling body structure is shown in figure 1 ).

[0058] In this embodiment, the casing cementing method of the horizontal well oil layer comprises the following steps:

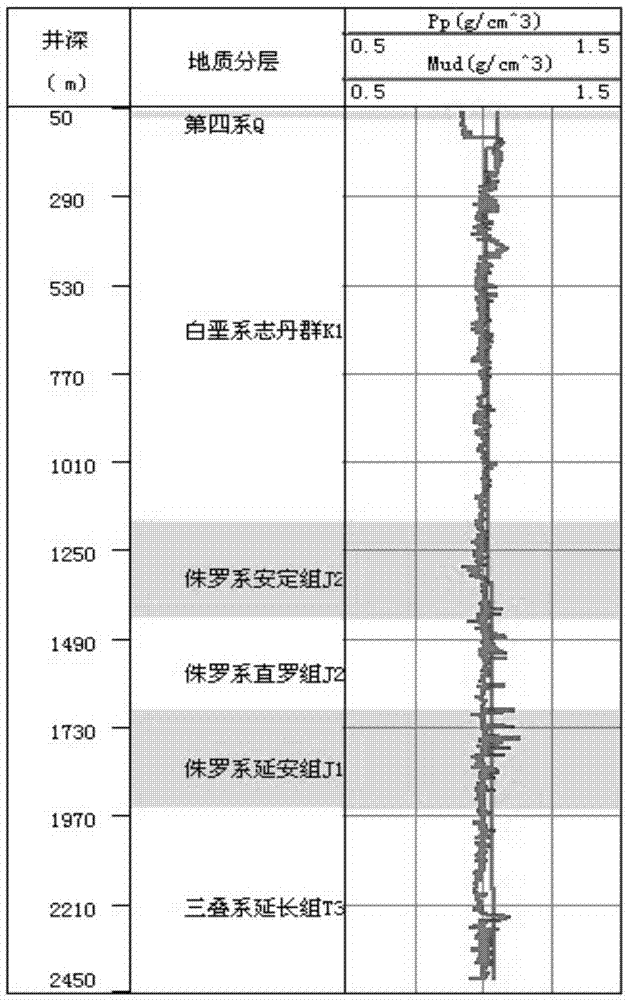

[0059] (1) According to the reservoir Chang 8 formation pressure coefficient of this well is 0.96 (the formation pressure profile of the adjacent well is shown in figure 2 ), it is determined that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com