Prefabricated and light floor cover plate and industrialized building house floor plate structure

A technology of floor slabs and floor slabs, which is applied in the direction of building components, building structures, floor slabs, etc., can solve the problems of unreachable, heavy weight, etc., and achieve the effects of noise reduction, light weight, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

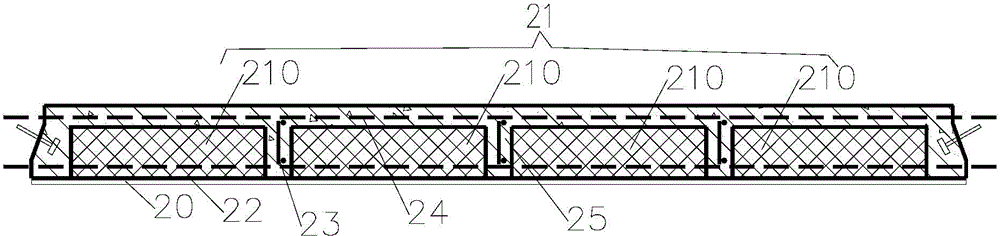

[0029] figure 1 The prefabricated lightweight floor slab 2 in the present invention is shown, and the prefabricated lightweight floor slab 2 is manufactured in a factory through an automated production line. The prefabricated lightweight floor slab 2 includes a finishing layer 20, a lightweight filling layer 21 arranged on the back of the finishing layer 20 formed by a number of lightweight filling blocks 210, used to connect the finishing layer 20 and the lightweight filling layer 21 fixedly positioned adhesive pieces 22, a steel skeleton sheet 23 is placed between the lightweight filling blocks 210, a steel mesh sheet 24 is laid behind the light filling layer 21, and a concrete structure layer 25 is poured after the light filling layer 21 , and the concrete structure layer 25 extends to the gap between the lightweight filling layers 21 and the veneer layer 20, the steel mesh sheet 24, the steel skeleton sheet 23 and the light filling layer 21 are bonded to form a whole.

[...

Embodiment 2

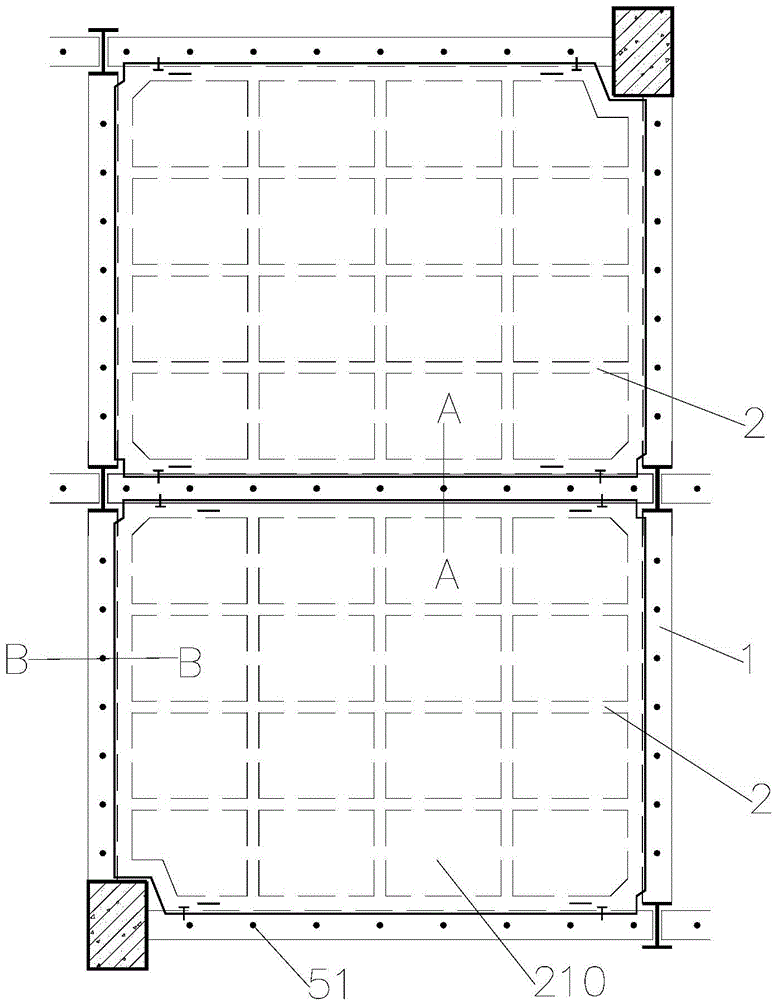

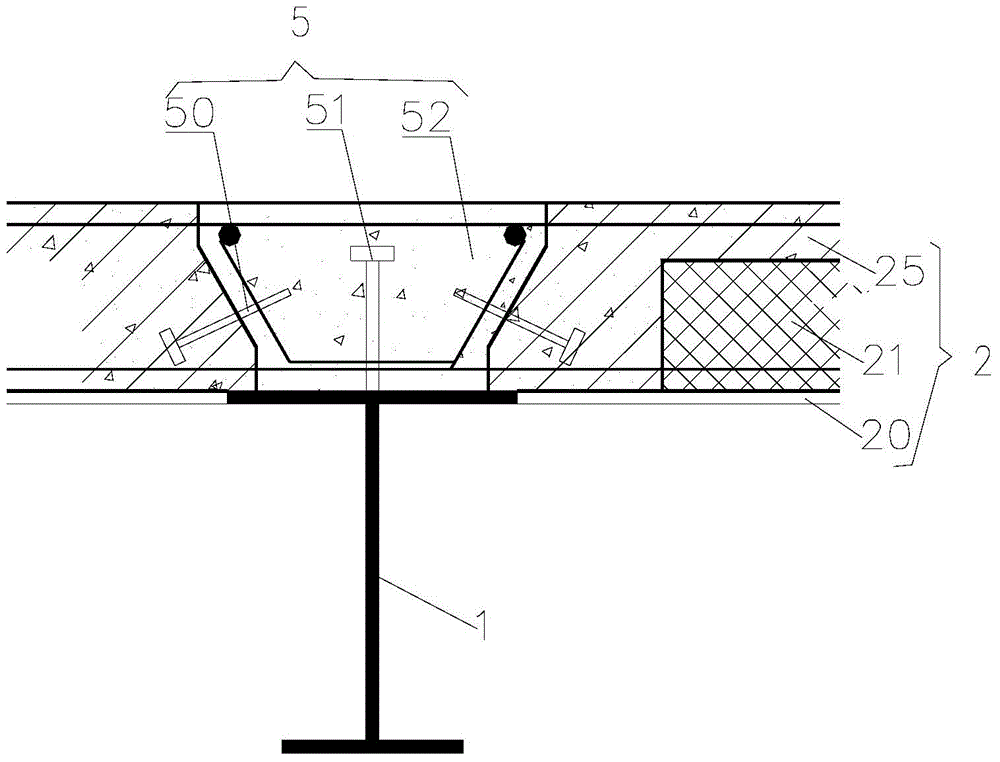

[0038] This embodiment discloses a floor plate structure of an industrialized building. The floor slab structure is arranged on the support beam 1 of the steel structure building, understandably, the support beam 1 is a steel beam made of steel material. Specifically, the floor slab structure of the industrial building includes several prefabricated lightweight floor slabs 2 arranged horizontally and fixed on the support beam 1, a prefabricated sinking tank 3 corresponding to the bathroom position, and a prefabricated balcony assembly 4 corresponding to the balcony position and Cast-in-place concrete connectors 5. Among them, the prefabricated lightweight floor slab 2, the prefabricated sinking tank 3 and the prefabricated balcony component 4 are all completed in the factory, and the prefabricated lightweight floor slab 2, the prefabricated sinking tank 3 and the prefabricated balcony component 4 are supported On the support beam 1, between adjacent prefabricated lightweight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com