Cover plate type fiber bragg grating sensor and packaging method thereof

A fiber grating and sensor technology, applied in the field of sensors, can solve the problems of fragile ceramic sensors, difficult grating packaging, and unfavorable on-site implementation, so as to improve production efficiency and production survival rate, not easy to decompose or fall off, and have good reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

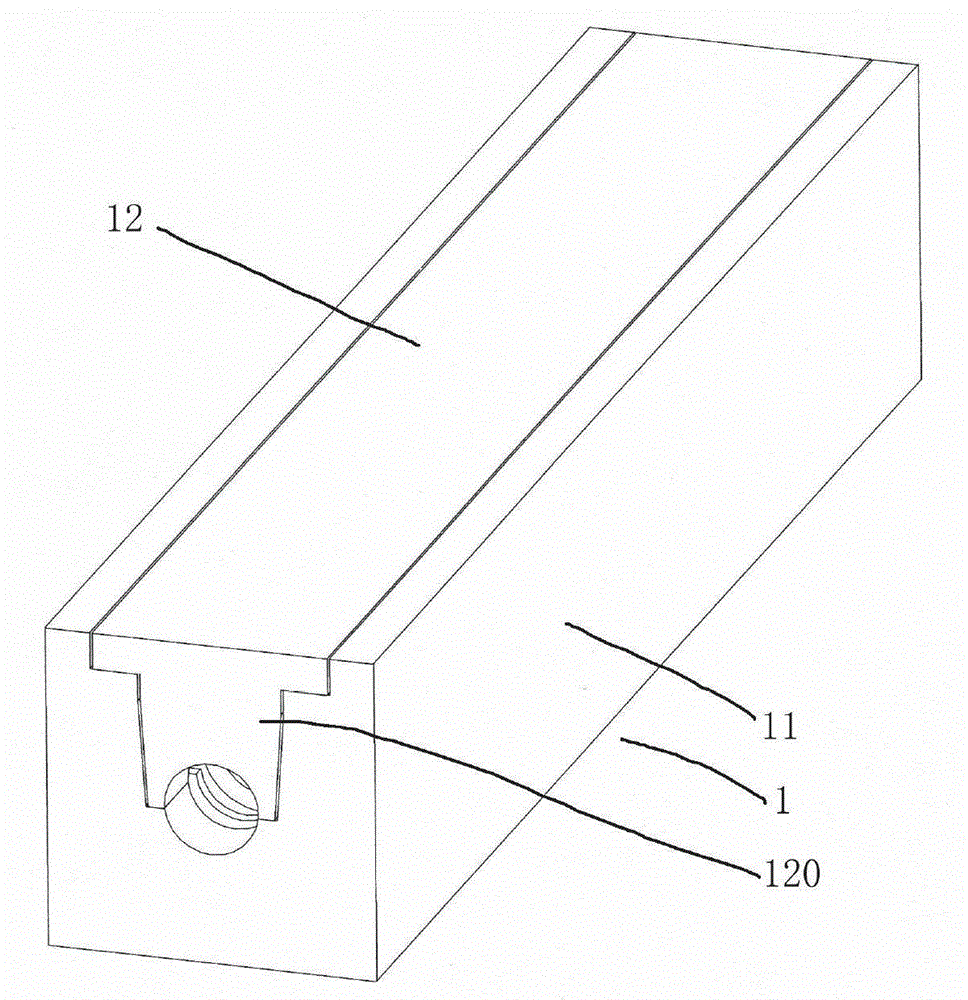

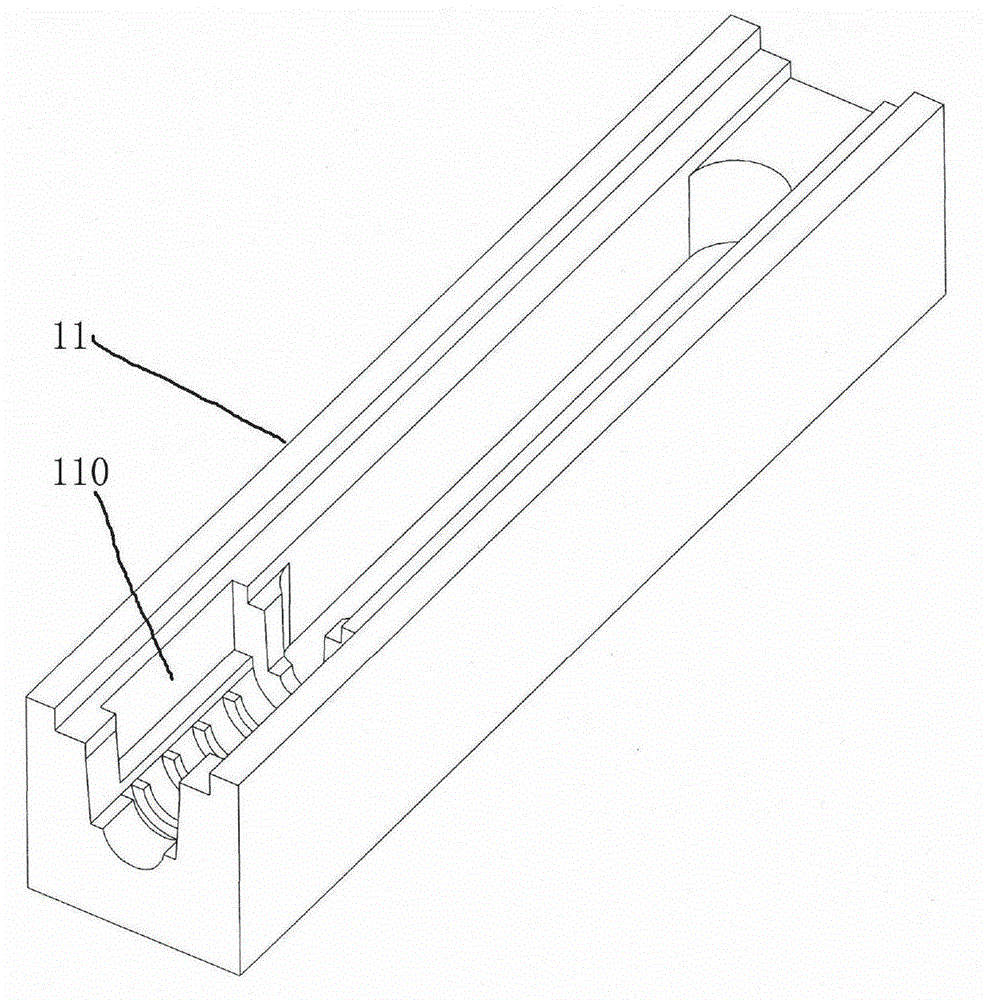

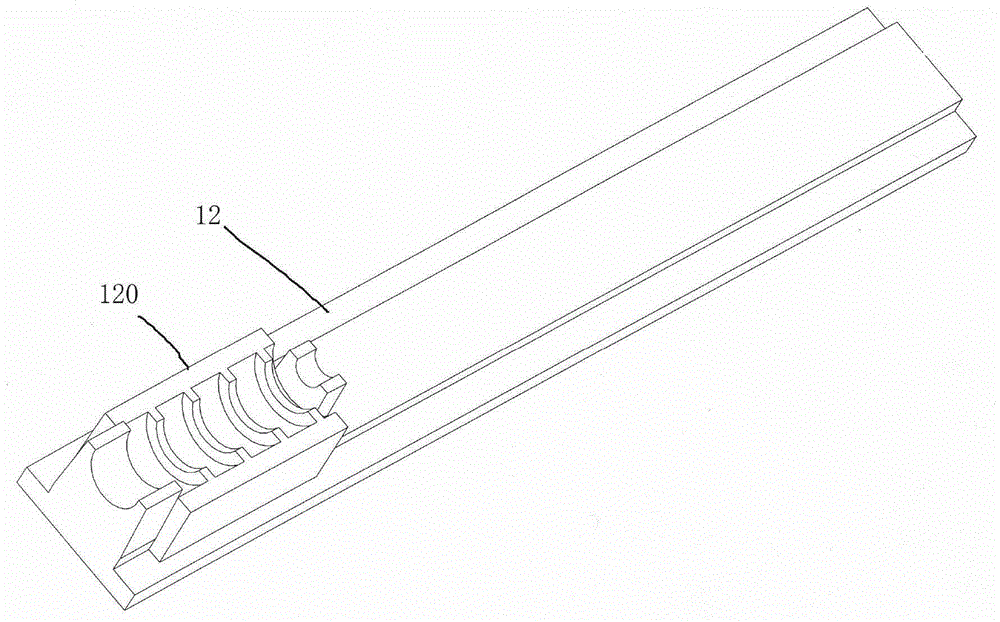

[0033] see Figure 1 to Figure 4 . The cover-type fiber grating sensor described in this embodiment includes a grating and a protective sleeve 2. Jumpers 21 and tensile fibers 22 are fixedly arranged in the protective sleeve 2, and one end of the protective sleeve 2 is fixedly connected to the flange interface. 3. The jumper 21 is an optical fiber, that is, an optical fiber, for transmitting optical signals. Flange interface 3 adopts FC / APC interface flange, which is the sensor signal output interface. The other end of the protective sleeve 2 is fixedly connected to the temperature sensing box 1. The temperature sensing box 1 includes two parts: the sensing protection groove 11 and the packaging cover plate 12. The grating is packaged in the temperature sensing box 1. The jumper 21 is connected to the grating It is connected inside the temperature sensing box 1. The temperature sensing box 1 senses and transmits the temperature to the grating. The light barrier then passe...

Embodiment 2

[0036] The packaging method of the cover-type fiber grating sensor includes the following four steps:

[0037] a) Pass the tensile fiber 22 through the protective sleeve 2 with a length of 510mm, and apply temperature-resistant AB glue evenly on all the interfaces of the sensing groove 11 and the packaging cover 12. That is to say, the temperature-resistant AB glue is coated on the contact part of the sensor protection groove 11 and the package cover 12 , and the contact parts of the sensor protection groove 11 , the package cover 12 and the protection sleeve 12 . Temperature-resistant AB glue has the characteristics of high thixotropy, high strength, high adhesion, good weather resistance, strong impact resistance and shear force, high temperature resistance up to 230 degrees, and excellent electrical insulation performance.

[0038] b) Select a jumper wire 21 that is 10mm longer than the protective sleeve 2, and weld a grating with a length of 15mm at the end, and the gratin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com