Zero-gravity flowmeter and weightlessness flow controller

A technology of flow controller and weightless method, applied in the direction of flow control using electric devices, etc., can solve the problems of complex structure, high cost and easy loss of flow detection equipment, and achieve the effects of low cost, simple on-site construction and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

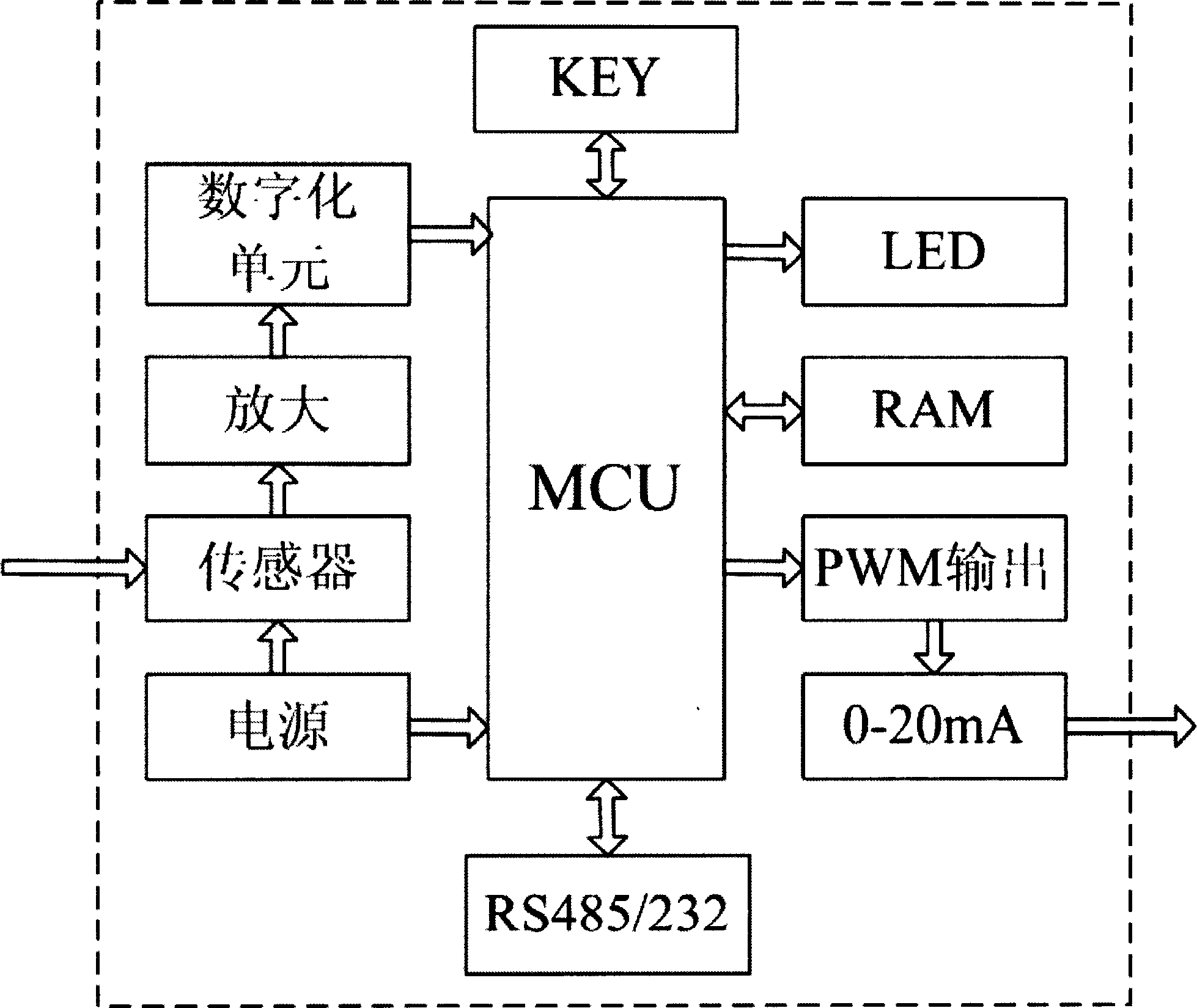

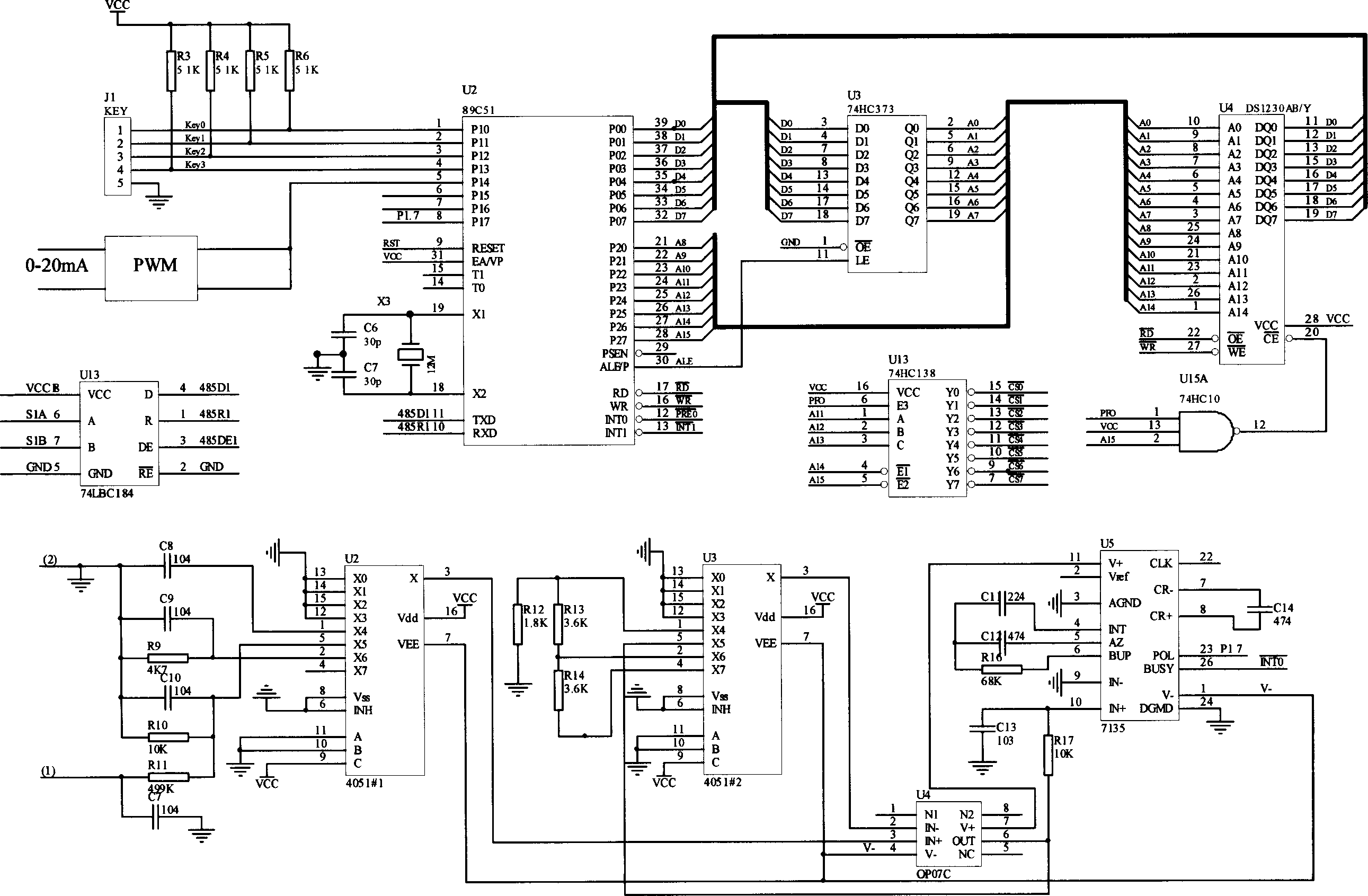

Method used

Image

Examples

Embodiment 1

[0028] The flow standard current signal or digital signal output by the weight loss method flowmeter is used in conjunction with other existing controllers.

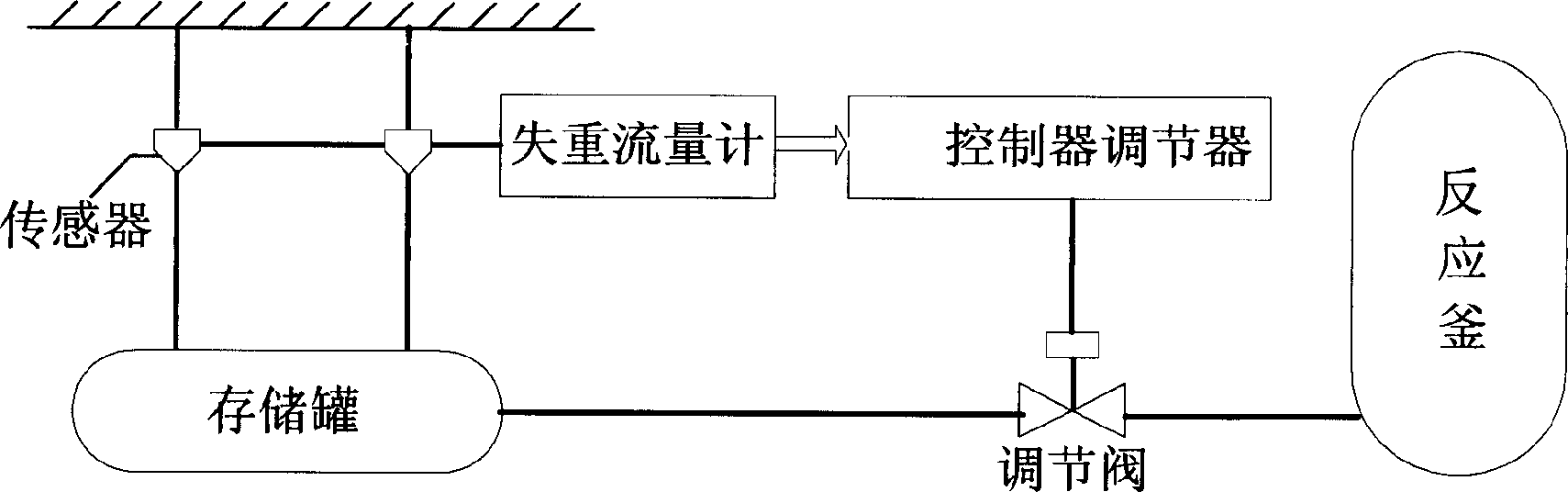

[0029] Such as image 3 , Figure 5 As shown, taking chlorine gas as an example to control the flow of chlorine gas in production, the liquid chlorine storage tank is lifted off the ground with a tension sensor at the production site (a hanger needs to be installed), or it is placed on a weighbridge supported by a pressure sensor (It is necessary to install a weighbridge). At this time, the weight signal of the liquid chlorine storage tank is input into the weight loss flowmeter through the tension (pressure) sensor. The weight of the chlorine storage tank will be reduced, and a weight difference will occur compared with the previous moment. The weight loss flowmeter calculates the flow (Kg / H), and the flow signal (0-20mA) is input into the controller regulator to adjust The outlet regulating valve of the liquid chlori...

Embodiment 2

[0031] Directly use the flow regulation signal output by the weight loss method flow controller to control the regulator to control the flow.

[0032] Similarly, using the weightlessness method flow controller, after being installed by suspension or weighbridge, the flow value can be directly compared with the given flow value by using the weightlessness principle, and the flow control actuator can be directly controlled by the control algorithm, so as to achieve flow control. Requirements, the use of the flow regulation signal output by the weight loss method flow controller to control the flow of the regulator is as follows: Figure 4 , Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com