Preparation method of multifunctional emulsion type drag reducer for shale gas fracturing

A multi-functional, drag-reducing agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as cumbersome dosing methods, and achieve the effect of simple and convenient on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation method of a kind of shale gas fracturing multifunctional emulsion type drag reducer mentioned in the present invention is as follows:

[0029] (1) Add 100 parts of white oil, 5 parts of Span80, 1 part of Tween81 into a 500mL beaker, add 0.0001 part of azobisisobutyronitrile as an initiator, dissolve and prepare an oil phase;

[0030] (2) Take 40 parts of deionized water, add 2 parts of acrylic acid, neutralize with potassium hydroxide to pH = 7, then add 14 parts of acrylamide, 2 parts of dimethyl diallyl ammonium chloride, 0.001 part of EDTA Disodium, 0.002 parts urea, formulated as an aqueous phase.

[0031] (3) Put the oil phase in a high-speed emulsifier, start the emulsifier, then add the water phase, and emulsify for 30 minutes to make a monomer emulsion.

[0032] (4) Put the monomer emulsion in a 500mL four-neck flask, pass nitrogen gas to deoxygenate for 30 minutes, turn off the nitrogen gas, turn on the stirring equipment, control...

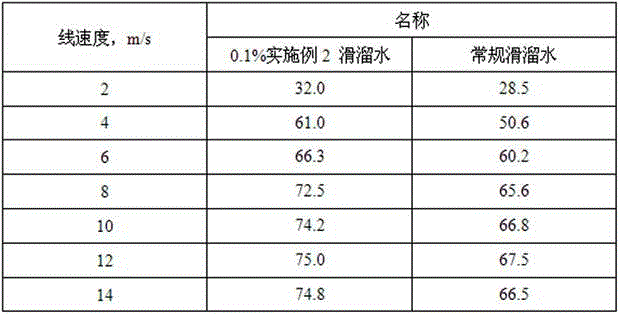

Embodiment 2

[0040] Embodiment 2: the preparation of the multifunctional emulsion type drag reducer mentioned in the present invention:

[0041] (1) Add 100 parts of white oil and 5 parts of Span80 into a 500mL beaker to dissolve and prepare the oil phase;

[0042] (2) Take 40 parts of deionized water, add 2 parts of acrylic acid, 1 part of 2-acrylamido-2-methylpropanesulfonic acid, neutralize with ammonia water to pH = 7, then add 15 parts of acrylamide, 2 parts Acryloyloxyethyltrimethylammonium chloride, 0.001 part of disodium EDTA, 0.002 part of urea; formulated as an aqueous phase.

[0043] (3) Put the oil phase in a high-speed emulsifier, start the emulsifier, then add the water phase, and emulsify for 30 minutes to make a monomer emulsion.

[0044] (4) Put the monomer emulsion in a 500mL four-neck flask, pass nitrogen gas to deoxygenate for 30 minutes, turn off the nitrogen gas, turn on the stirring equipment, control the speed at 100 rpm, control the temperature at 40°C, react for ...

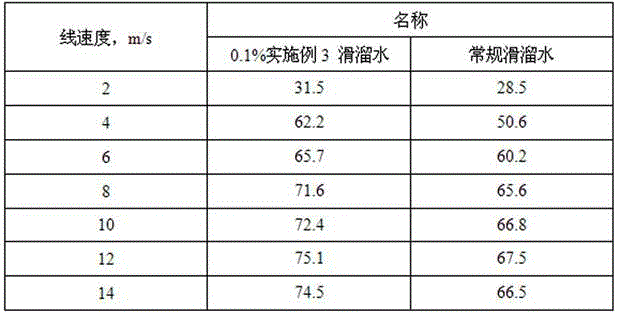

Embodiment 3

[0052] Embodiment 3: the preparation of the multifunctional emulsion type drag reducer mentioned in the present invention:

[0053] (1) Add 100 parts of cyclohexane, 4 parts of Span80, 1 part of Span83, 1 part of Tween81 into a 500mL beaker, add 0.0001 part of azobisisobutyronitrile as an initiator, dissolve and prepare an oil phase;

[0054] (2) Take 40 parts of deionized water, add 1 part of acrylic acid, neutralize with potassium carbonate to pH = 7, then add 15 parts of acrylamide, 3 parts of trimethallyl ammonium chloride, 0.001 part of disodium EDTA , 0.002 parts of urea; formulated as an aqueous phase.

[0055] (3) Put the oil phase in a high-speed emulsifier, start the emulsifier, then add the water phase, and emulsify for 30 minutes to make a monomer emulsion.

[0056] (4) Put the monomer emulsion in a 500mL four-neck flask, pass nitrogen gas to deoxygenate for 30 minutes, turn off the nitrogen gas, turn on the stirring equipment, control the speed at 100 rpm, contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com