Laser net shape manufacturing and repair using a medial axis toolpath deposition method

a technology of toolpath deposition and laser net, which is applied in the direction of manufacturing tools, soldering devices, turbines, etc., can solve the problems of rejecting and scrapping the entire, reducing the number of lack of fusion imperfections in the solid deposit, and reducing the cost of final product production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

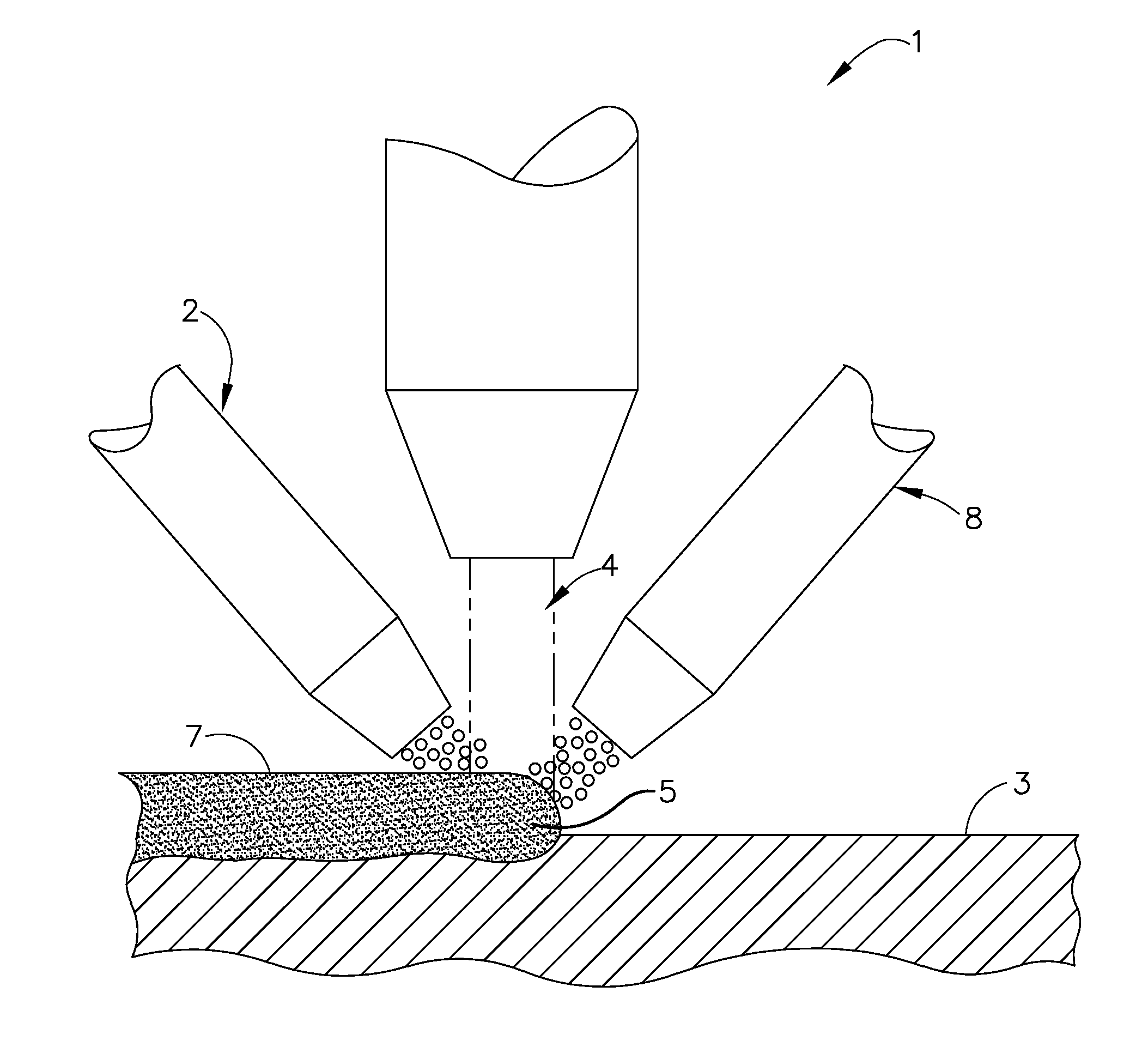

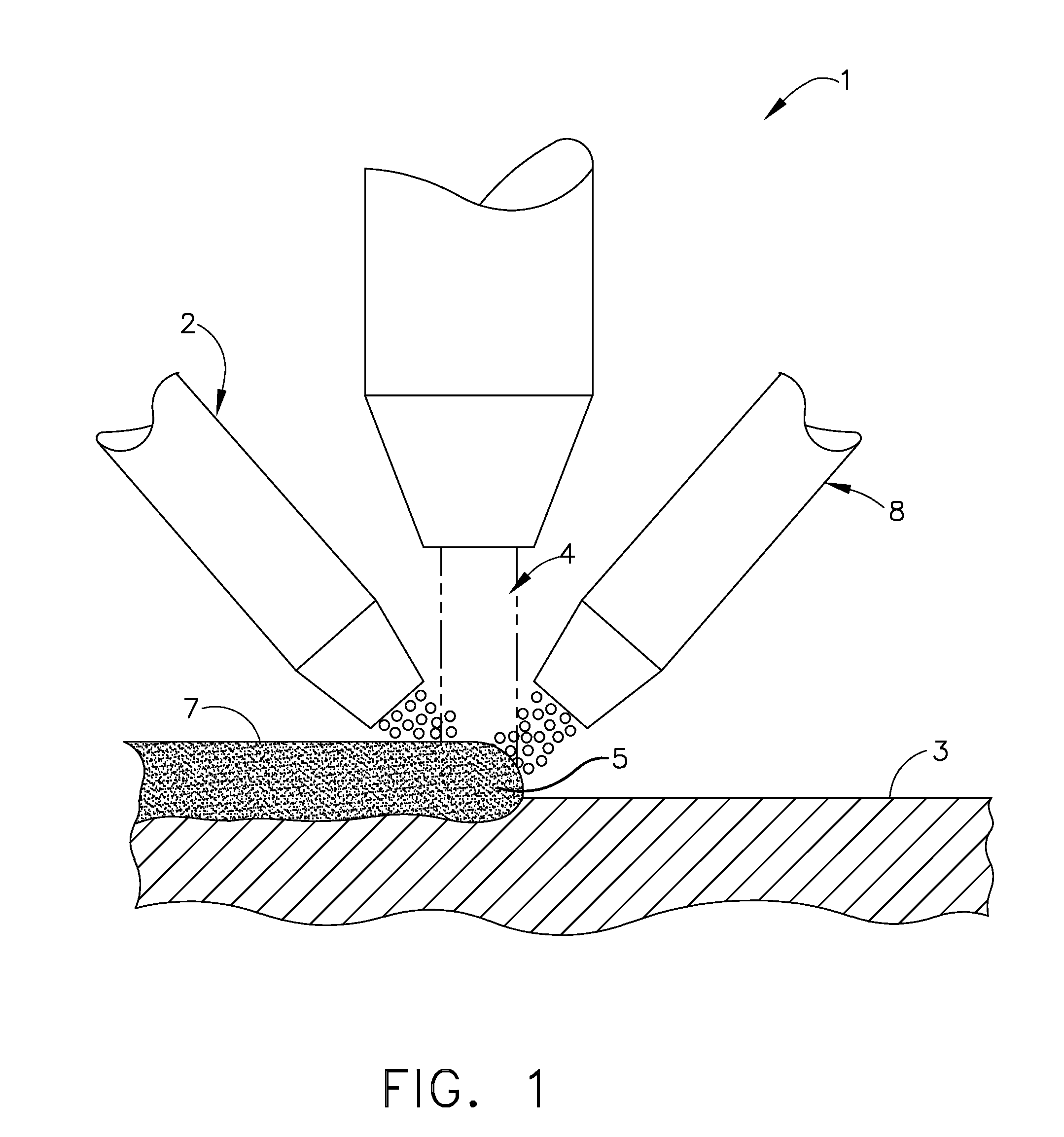

[0026]In Laser Net Shape Manufacturing (LNSM), the dimensions and overall geometry of the repair are rendered in accordance with a computer-aided design (CAD) description. The geometry of the repair must be described mathematically. Modeling of the shapes is achieved through the use of a CAD system, and from these representations, tool paths are generated to drive the LNSM process.

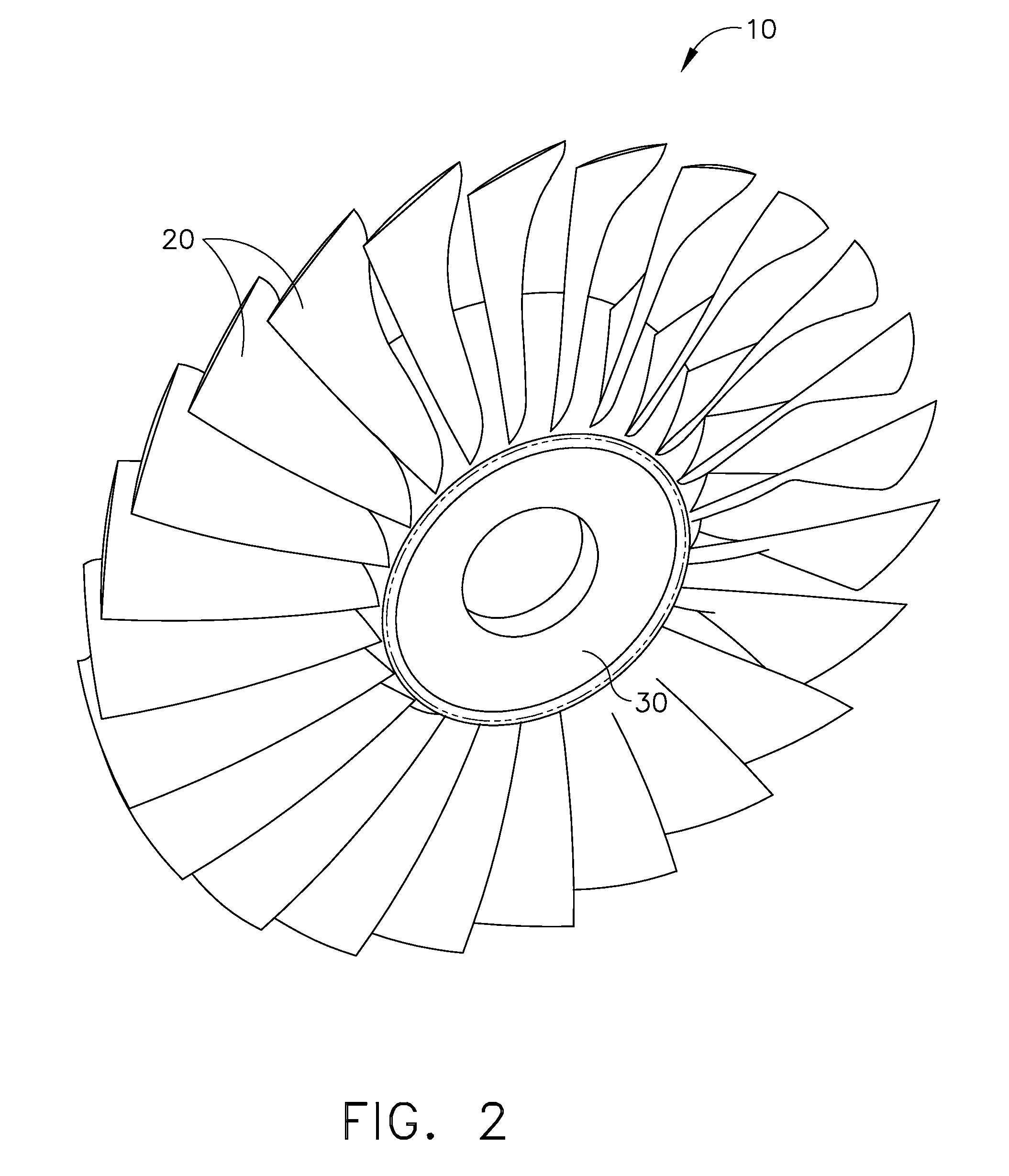

[0027]A CAD model of a part to be fabricated or repaired is generated by numerically characterizing the shape of the article such as a blade from drawings or a part prepared by more conventional methods such as machining. Once the shape of the part is numerically characterized, the computer generates a series of uniform slices along the desired direction of material buildup, and the computer determines a medial axis or spine (hereinafter referred to as a medial axis) for each slice. Based on a predetermined width of a bead of deposited material, it may be necessary to apply more than one pass of material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com