Bionic squirm type pipeline travelling mechanism and control method thereof

A technology of walking mechanism and pipeline, which is applied in the field of bionic robots, can solve the problems affecting the stability and reliability of the mechanism, the decline of output capacity, and the rapid temperature rise of the coil, etc., so as to facilitate popularization and promotion, easy processing and manufacturing, and prevent the mechanism from being stuck. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

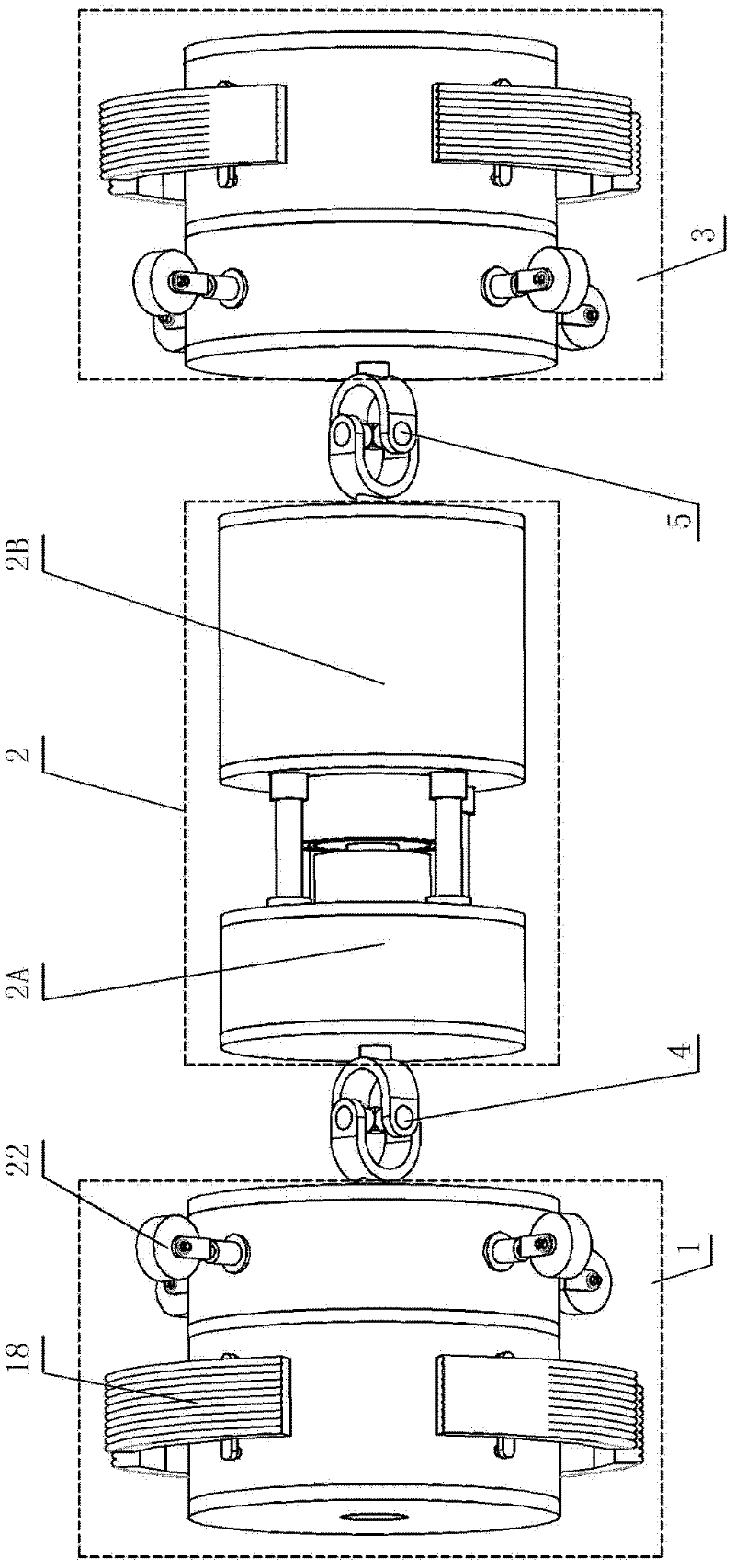

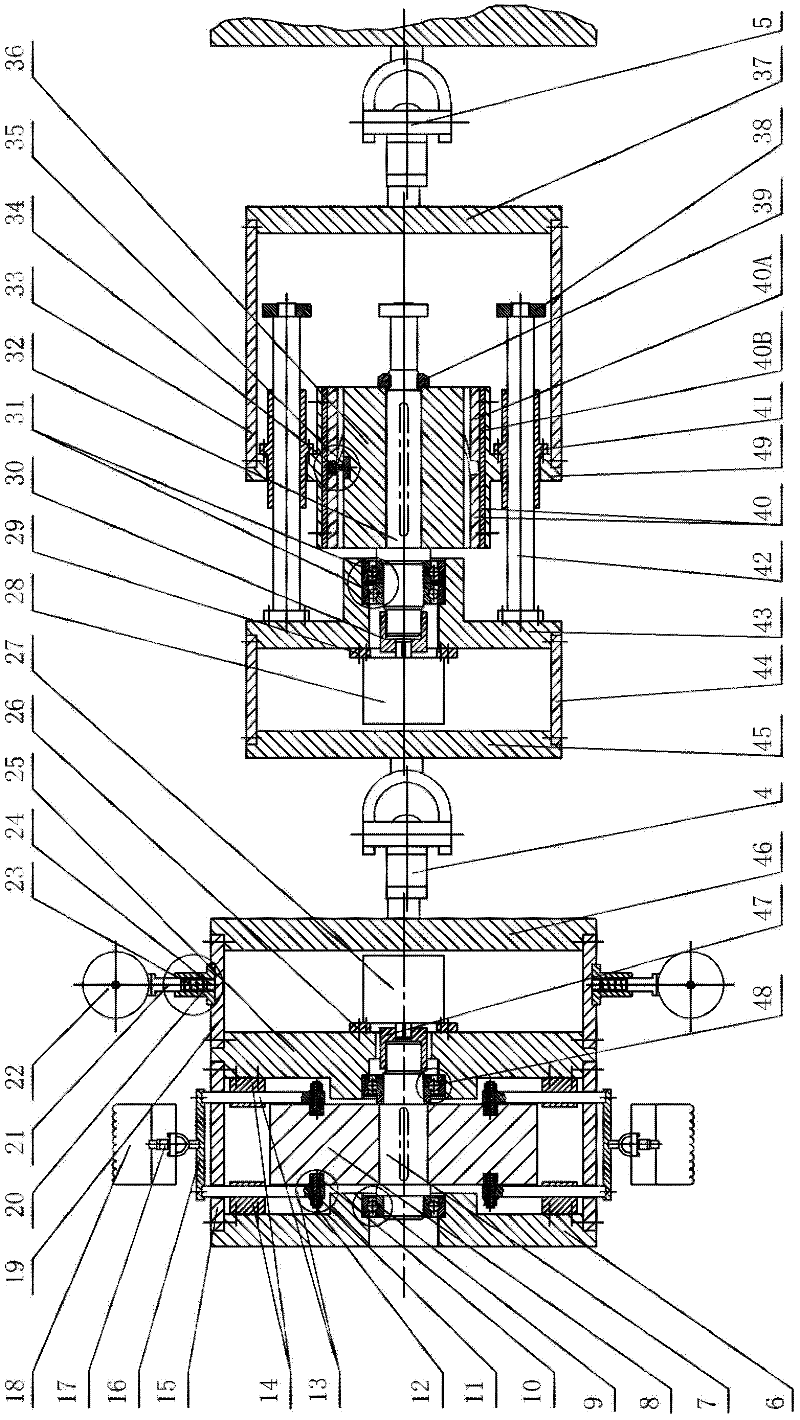

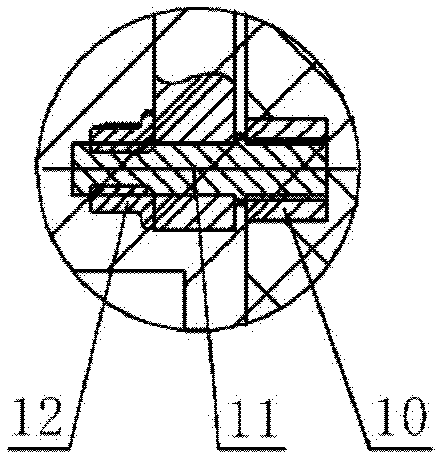

[0053] figure 1 Shown is the external structure of the bionic peristaltic pipeline running mechanism in this embodiment, which is composed of the front body segment radial support unit 1 , the middle axial feed unit 2 and the rear body segment radial support unit 3 . The radial support unit 1 of the front body segment and the radial support unit 3 of the rear body segment are arranged symmetrically at both ends of the middle axial feed unit 2, which can realize periodic intermittent radial expansion and tightening between the body segment and the inner wall of the pipeline. Retraction movement; the radial support unit 1 of the front body segment and the radial support unit 3 of the rear body segment are evenly distributed along the circumference of the shell at least two radially telescopic support claws 18 and the same generatrix position as the support claws 18 The guide roller 22 can maintain the self-centering and shape-closed functions of the mechanism in the running pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com