Bearing-gear multi-fault coupled simulation experiment table

A simulation experiment and multi-fault technology, applied in mechanical bearing testing, machine gear/transmission mechanism testing, teaching models, etc., to facilitate fault monitoring and diagnosis, and improve learning and cognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

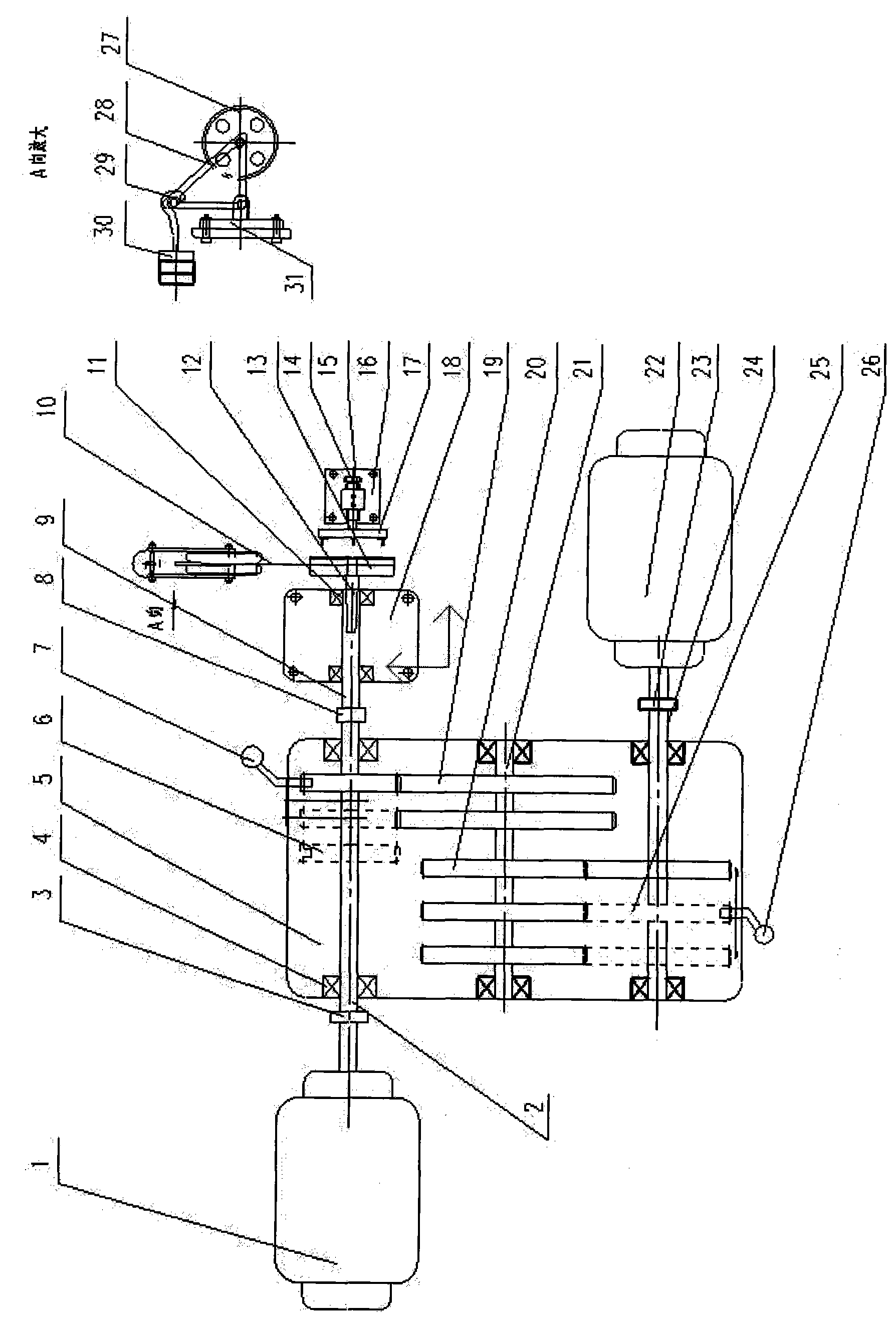

[0009] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0010] see figure 1 , the present invention includes a first DC adjustable speed motor 1, the output shaft of the first DC adjustable speed motor 1 is connected with the input shaft 2 of the gear box 5 through an elastic coupling 3, and the input shaft 2 is connected through a coupling 8 is connected with the drive shaft 9 of the bearing box 18, and the sliding bearing 11 supporting the drive shaft 9 of the bearing box is also arranged in the bearing box 18, and the spindle 12 of the bearing box 18 is provided with a replaceable bearing sleeve 13. One side of the replaceable bearing sleeve 13 is provided with a support box 16, and the top 15 and the top adjustment screw 14 for adjusting the top 15 are arranged in the support box 16. Between the support box 16 and the replaceable bearing sleeve 13, a The top p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com