Pressure cylinder type liquid-solid mixed jet experimental device

A technology of experimental devices and pressurized cylinders, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of less research, stay at the level of theoretical analysis, and insufficient research, and achieve multiple functions, simple and clear system structure, and convenient The effect of installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

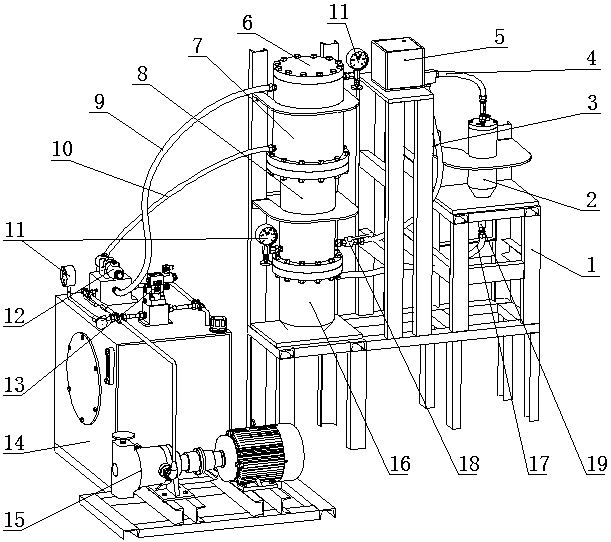

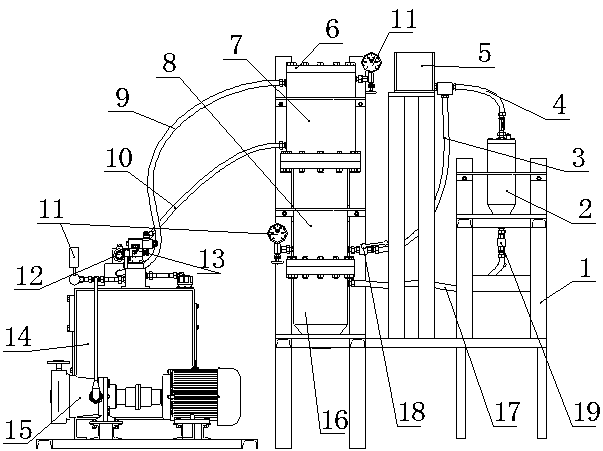

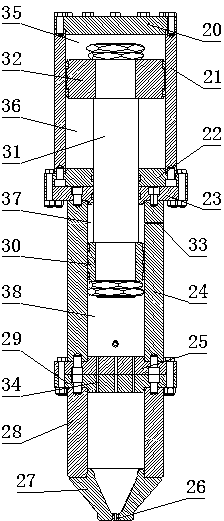

[0019] Such as Figure 1-3 As shown, a pressurized cylinder type liquid-solid mixed jet experimental device, it includes a bracket 1, the abrasive tank 2 is fixed on the bracket 1, and the upper surface of the abrasive tank 2 is connected to the high-level water tank 5 through the pipeline A4 , the bottom end of the abrasive tank 2 is provided with a discharge port A, the discharge port A is connected to the sand mixing chamber 16 through a pipeline B17, and a shut-off valve B19 is connected to the pipeline B17. The sand chamber 16 includes a conical cylinder 27, a sand mixing chamber cylinder 28 and a sand mixing chamber upper cover 29. The conical cylinder 27 is connected with a nozzle 26, and the above of the sand mixing chamber 16 is connected with Booster cylinder 6, described booster cylinder 6 includes cylinder body A7 and cylinder body B8, described cylinder body A7 includes cylinder body A21, upper end cover A20 and lower end cover A22, described upper end cover A20 a...

Embodiment 2

[0022] Such as Figure 1-3As shown, a pressurized cylinder type liquid-solid mixed jet experimental device, it includes a bracket 1, the abrasive tank 2 is fixed on the bracket 1, and the upper surface of the abrasive tank 2 is connected to the high-level water tank 5 through the pipeline A4 , the bottom end of the abrasive tank 2 is provided with a discharge port A, the discharge port A is connected to the sand mixing chamber 16 through a pipeline B17, and a shut-off valve B19 is connected to the pipeline B17. The sand chamber 16 includes a conical cylinder 27, a sand mixing chamber cylinder 28 and a sand mixing chamber upper cover 29. The conical cylinder 27 is connected with a nozzle 26, and the above of the sand mixing chamber 16 is connected with Booster cylinder 6, described booster cylinder 6 includes cylinder body A7 and cylinder body B8, described cylinder body A7 includes cylinder body A21, upper end cover A20 and lower end cover A22, described upper end cover A20 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com