Machining method and device for vane channels of uniform-cross section profile cowled integral impeller

A technology of integral impeller and processing method, which is applied in the field of flow channel processing of integral impeller with crown and cross-section, can solve the problems of low efficiency and long processing time, simplify analysis, improve processing efficiency, and reduce design and manufacturing costs. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

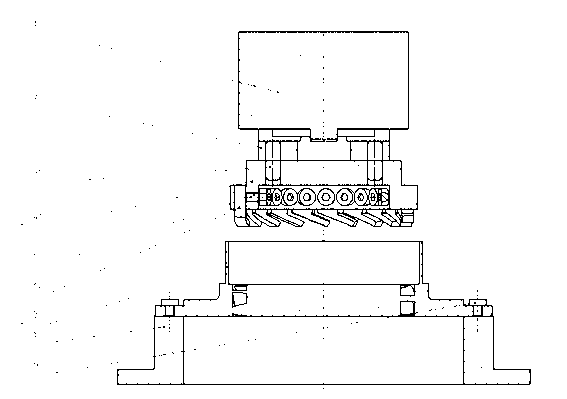

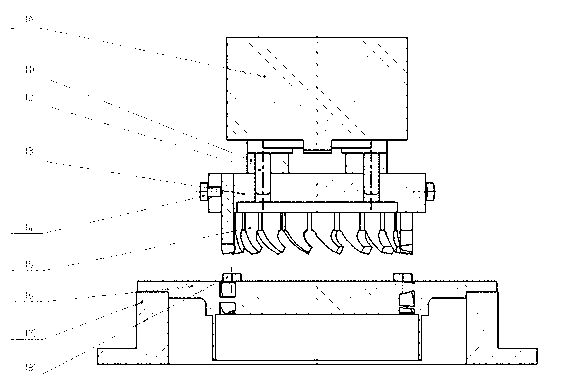

[0042] like Figure 5 The blade-type shrouded impeller with constant cross-section shown in the figure means that the shape of the cross-section of the blade in the radial direction (the radial direction of the blade in the cross-sectional view in the figure corresponds to the Z-axis direction) is consistent with the constant cross-section.

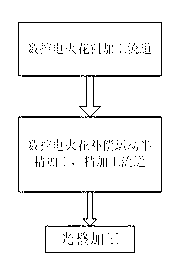

[0043] like image 3 As shown, a numerical control electric discharge machining method for the channel between the blades of an equal-section airfoil with a crown integral impeller includes the following processing steps: firstly design the near-formed electrodes in the inlet processing area and the outlet processing area of the flow channel respectively, and first use 19 inlets The near-formed electrode in the processing area performs CNC EDM on the inlet processing area of all inter-blade flow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com