Ultrahigh pressure cylinder

A technology of ultra-high pressure cylinder and outer cylinder, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of increasing temperature difference between inner wall and outer wall, affecting the safety of the unit, increasing thermal stress, etc., to achieve strong practicability and safety The effect of high reliability and ease of difficulty in design and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] see Figure 4 : The present invention is applied to the secondary reheating unit, which is mainly composed of boiler 1, ultra-high pressure cylinder 2, high-pressure cylinder 3, medium-pressure cylinder 4, low-pressure cylinder 5, generator 6, condenser 7, and Feed water pump 8 constitutes. In order to facilitate the delivery of steam to the present invention, a high-pressure heater 9 is added on the unit, and the high-pressure heater 9 is arranged between the boiler 1 and the feed water pump 8 .

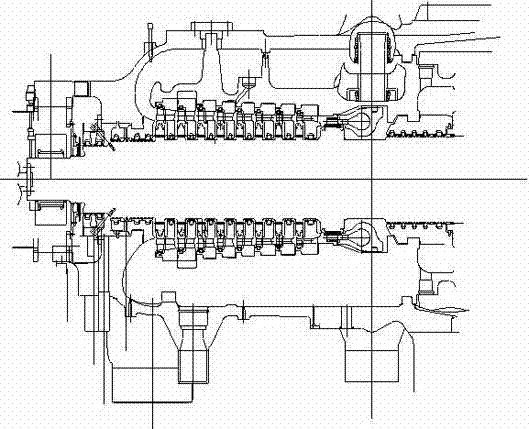

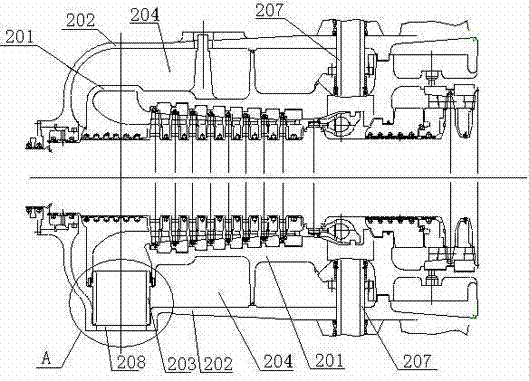

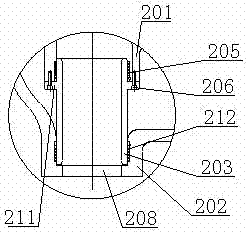

[0024] see figure 2 and image 3 : The present invention includes an inner cylinder 201 and an outer cylinder 202. Wherein, the inner cylinder 201 is installed in the outer cylinder 202, and the outer cylinder 202 is connected with a steam inlet pipe 207 and an exhaust pipe 210, and the steam inlet pipe 207 is connected from the boiler 1, and the steam inlet pipe 207 passes through the outer cylinder 202 and extends to The inner cylinder 201 and the steam inlet pipe 207 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com