Modularized walking robot with flexible torso

A walking robot and modular technology, applied in the field of robotics, can solve the problems of poor robot flexibility, increased robot, heavy weight, etc., to achieve the effects of high movement flexibility and stability, reduced reactive power loss, and strong obstacle-crossing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

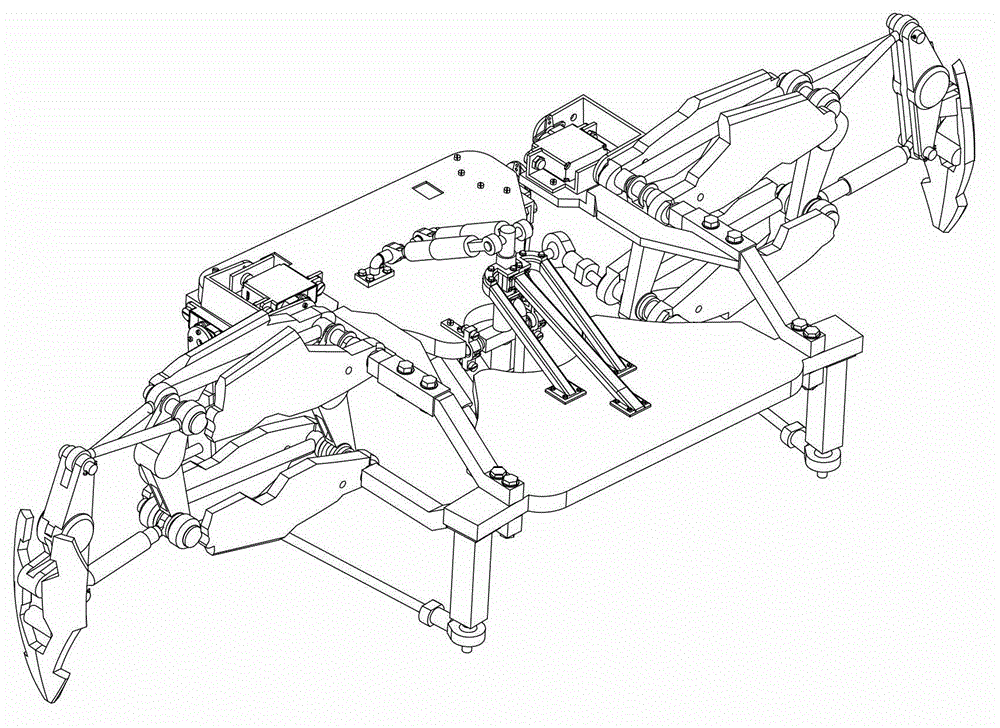

[0023] to combine Figure 1-7 , the walking robot with flexible torso modularization of the present invention is made up of following several parts: Modular structure fuselage front end 67, modular structure fuselage middle end 66, modular structure fuselage rear end 64, body connecting frame 65, hexagonal head Bolt 63.

[0024] The whole machine is assembled as follows: the front end 67 of the modular structure fuselage, the middle end 66 of the fuselage, and the rear end 64 of the fuselage are connected to each other with the connecting frame 65 of the fuselage by hexagon head bolts 63.

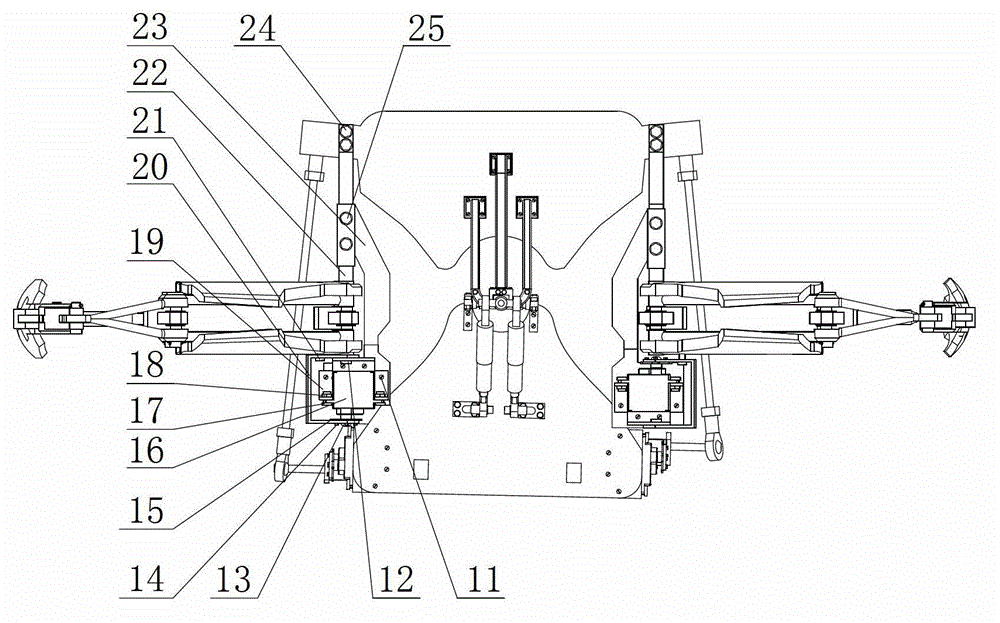

[0025] to combine image 3 Each modular fuselage structure consists of two walking legs distributed on both sides of the body and a compliant torso with two degrees of freedom.

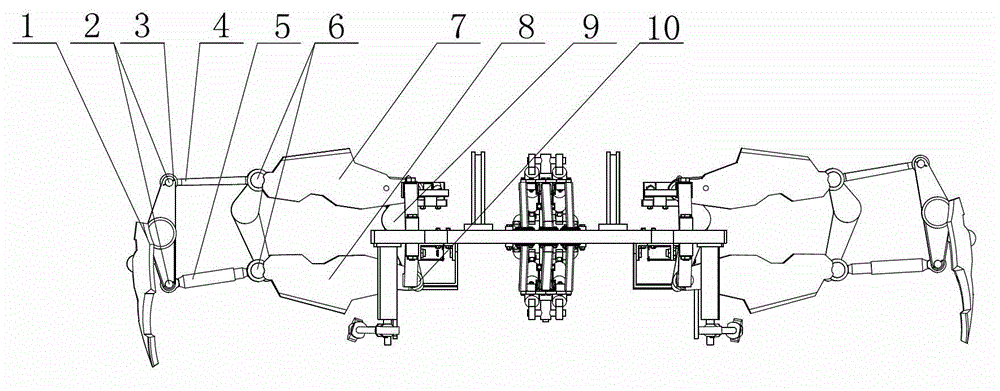

[0026] to combine figure 1 and figure 2 , the walking robot includes walking feet, which spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com