The dynamic compensation method of digital frequency conversion controller specially for industrial metering pump

A dynamic compensation, digital frequency conversion technology, applied in vector control systems, control of electromechanical brakes, control of electromechanical transmissions, etc., can solve problems such as shortened life, equipment impact damage, and drive motor heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

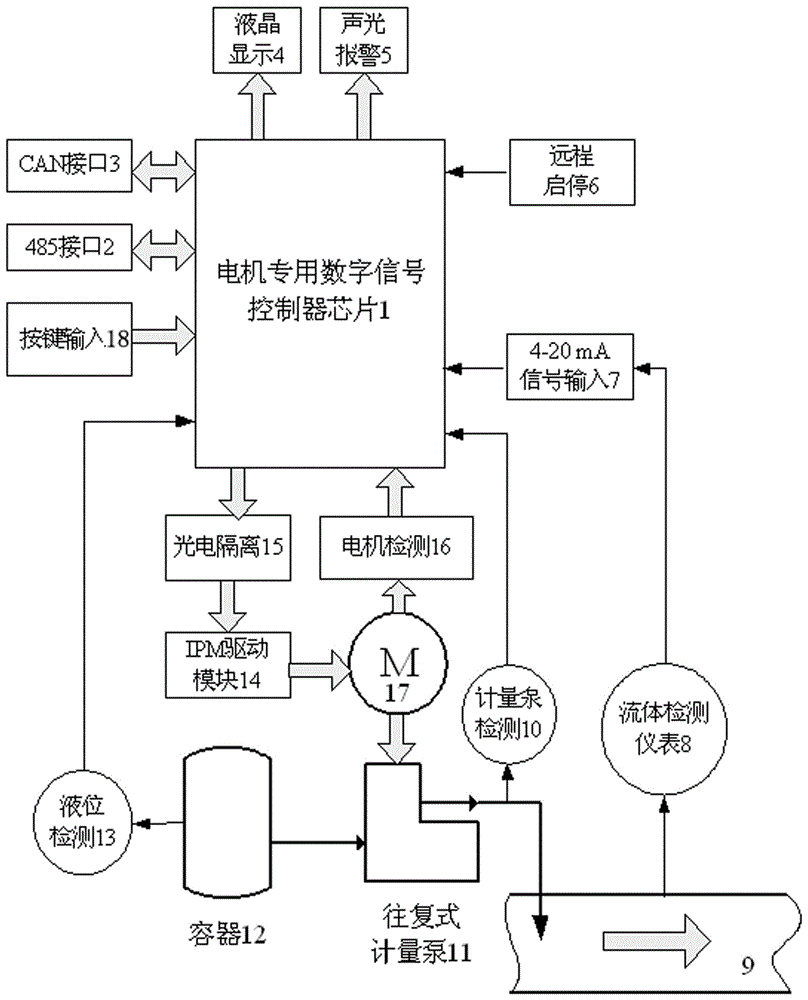

[0014] In order to illustrate the content of the present invention, first introduce the application system of the digital frequency conversion metering pump as a whole. as attached figure 1 As shown, the system takes the motor-specific digital signal controller chip 1 as the core, has key input 18 and liquid crystal display 4, and is used to realize parameter configuration and working mode setting through human-computer interaction. Realize remote monitoring through CAN bus interface 3 and 485 interface 2. Use the remote start and stop 6 to manually control the start and stop of the metering pump.

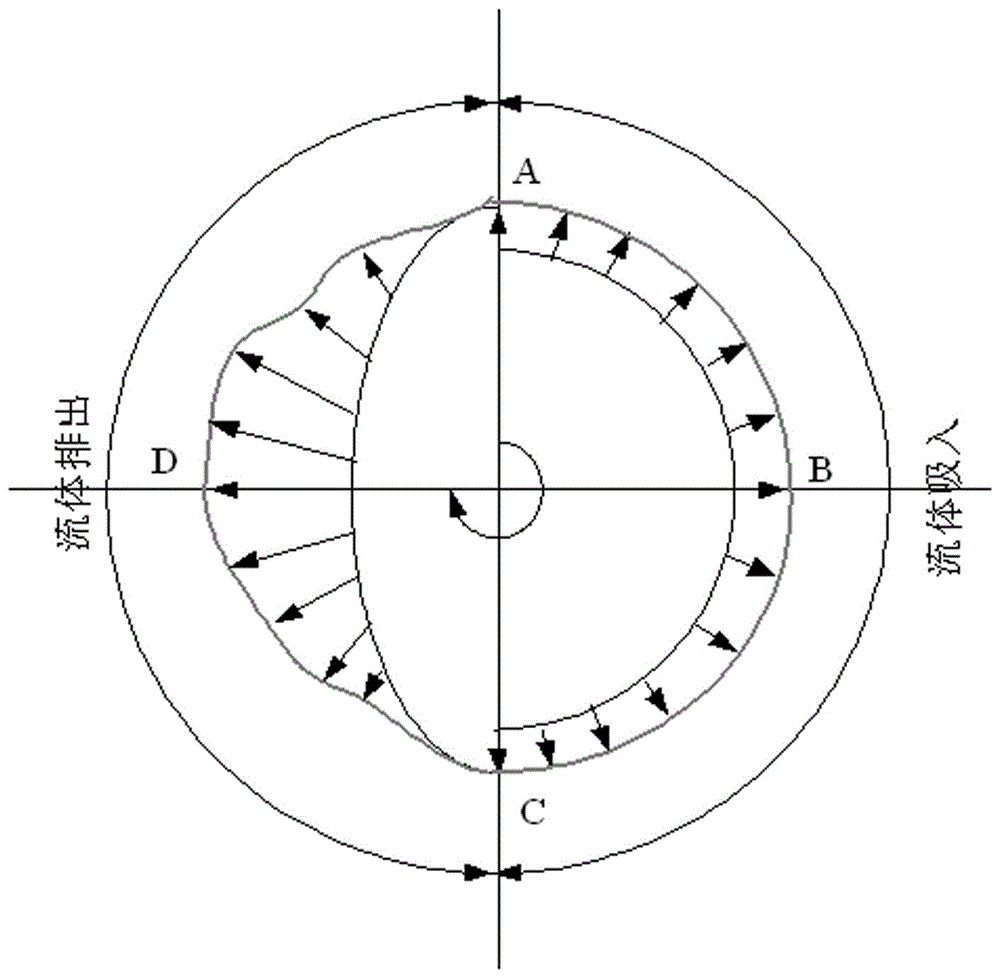

[0015] Through the 4-20mA standard signal input interface, the signal from the flow detection instrument 8 or other external controllers can be tracked to realize closed-loop control. Driven by a three-phase asynchronous AC motor, the reciprocating metering pump 11 transports the fluid to be added from the container 12 to the dosing point 9 through vacuum principle and extrusion....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com