Stable operation method for restraining deteriorated alusil alloy strontium from inhaling

A technology of aluminum-silicon alloy and operation method, which is applied in the field of stable operation, aluminum-silicon alloy strontium degeneration and inhibition of gas absorption, can solve the problems of inability to achieve long-term heat preservation pouring, inability to apply high-end aluminum castings, etc., to extend the effective time, gas The effect of content reduction and avoidance of aspiration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

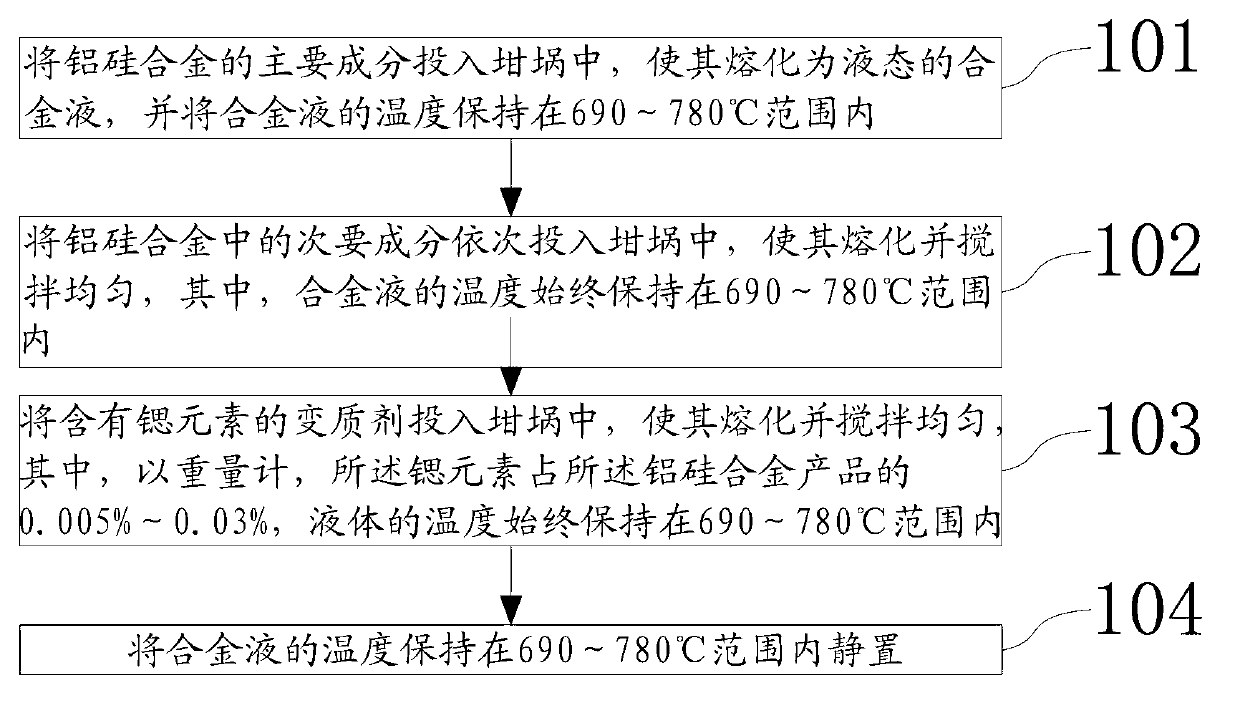

[0049] Embodiment 1 of the present invention provides a stabilizing operation method for deteriorating strontium of aluminum-silicon alloy and suppressing gettering, such as figure 1 shown, including the following steps:

[0050]101) Put the main components of the aluminum-silicon alloy into the crucible to melt it into a liquid alloy liquid, and keep the temperature of the alloy liquid within the range of 690-780°C;

[0051] 102) Put the secondary components of the aluminum-silicon alloy into the crucible one by one to melt and stir evenly, wherein the temperature of the alloy liquid is always kept within the range of 690-780°C;

[0052] 103) Put the modifier containing strontium element into the crucible, melt it and stir evenly, wherein, by weight, the strontium element accounts for 0.005%-0.03% of the aluminum-silicon alloy product, and the temperature of the liquid is always kept at In the range of 690~780℃;

[0053] 104) Keep the temperature of the alloy liquid in the ...

Embodiment 2

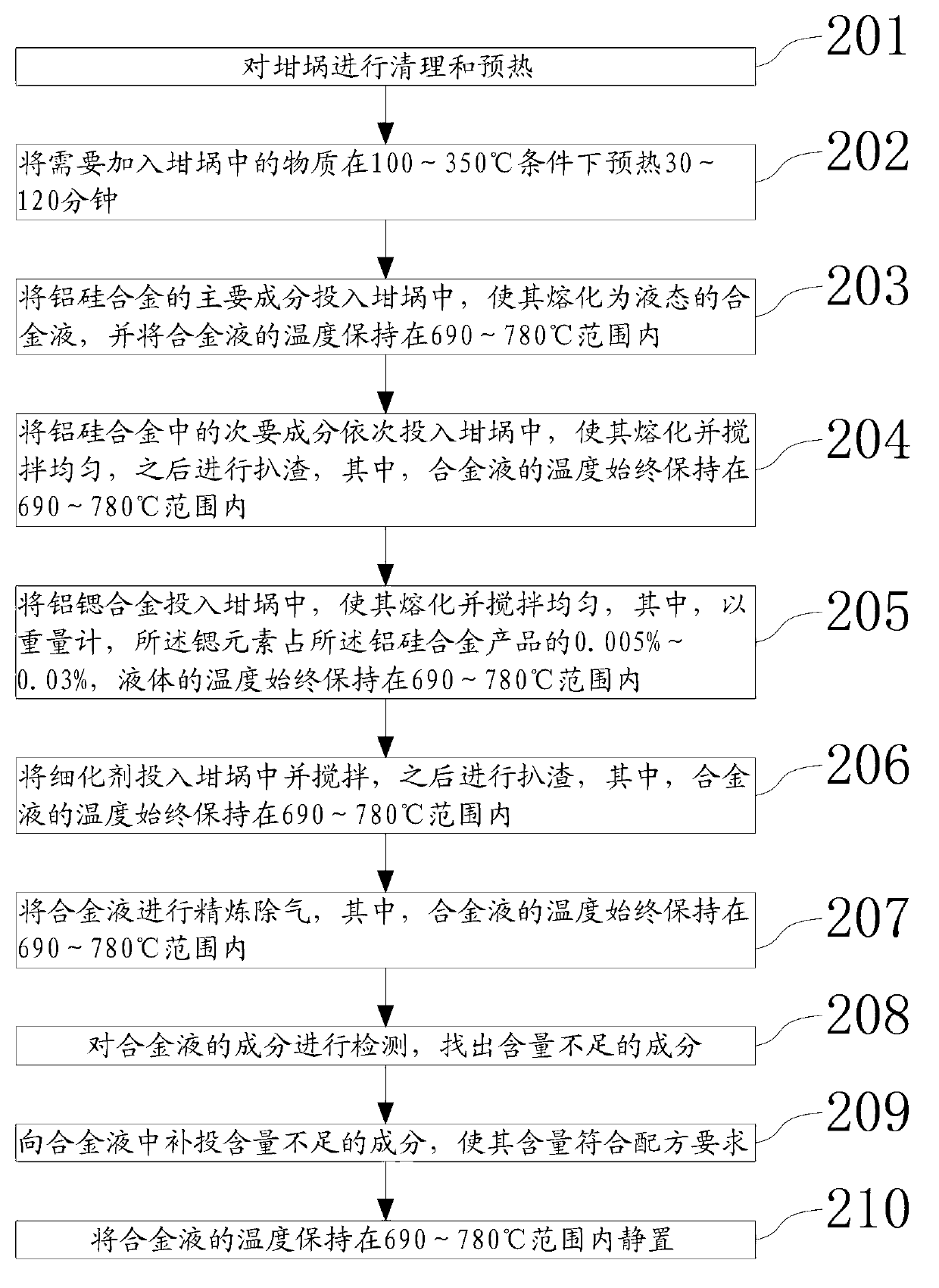

[0058] In order to further improve the effect, Embodiment 2 of the present invention improves the stabilizing operation method of Al-Si alloy strontium modification to suppress gettering on the basis of Embodiment 1, such as figure 2 shown, including the following steps:

[0059] 201) Cleaning and preheating the crucible;

[0060] 202) Preheating the substances to be added into the crucible at 100-350°C for 30-120 minutes;

[0061] 203) Put the main components of the aluminum-silicon alloy into the crucible to melt it into a liquid alloy liquid, and keep the temperature of the alloy liquid within the range of 690-780°C;

[0062] 204) Put the secondary components in the aluminum-silicon alloy into the crucible in turn, melt them and stir them evenly, and then remove the slag, wherein the temperature of the alloy liquid is always kept in the range of 690-780°C;

[0063] 205) Put the aluminum-strontium alloy into the crucible, melt it and stir it evenly, and then remove the sl...

Embodiment 3

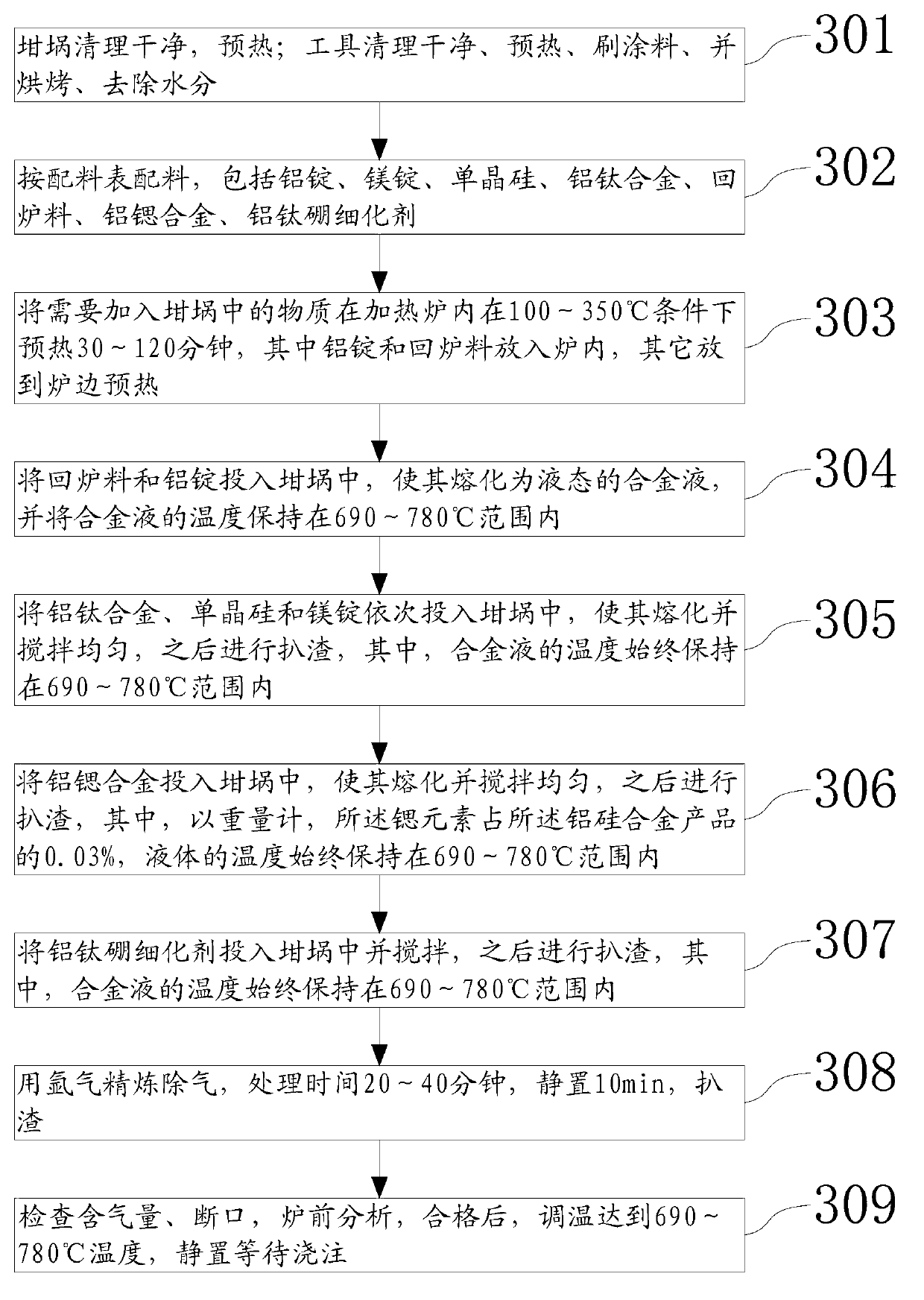

[0082] Embodiment 3 of the present invention takes the smelting process of ZL114A or ZL101A alloy as an example to describe in detail. Such as image 3 shown, including the following steps:

[0083] 301) The crucible is cleaned and preheated; tools are cleaned, preheated, painted, and baked to remove moisture;

[0084] 302) Ingredients according to the ingredient list, including aluminum ingots, magnesium ingots, single crystal silicon, aluminum-titanium alloys, recycled materials, aluminum-strontium alloys, aluminum-titanium-boron refiners;

[0085] 303) Preheat the materials that need to be added to the crucible in the heating furnace at 100-350°C for 30-120 minutes, put the aluminum ingots and recycle materials into the furnace, and put the others on the edge of the furnace for preheating;

[0086] 304) Putting the returned material and aluminum ingot into the crucible to melt it into a liquid alloy liquid, and keeping the temperature of the alloy liquid within the range ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com