Reluctance type linear oscillating motor and its integrative application device and power supply method

A reluctance type and motor technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of increasing the size of the application device, the utilization of power supply voltage, and increasing the reactive power loss of the motor, so as to achieve the goal of increasing the volume and cost, and improving the utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

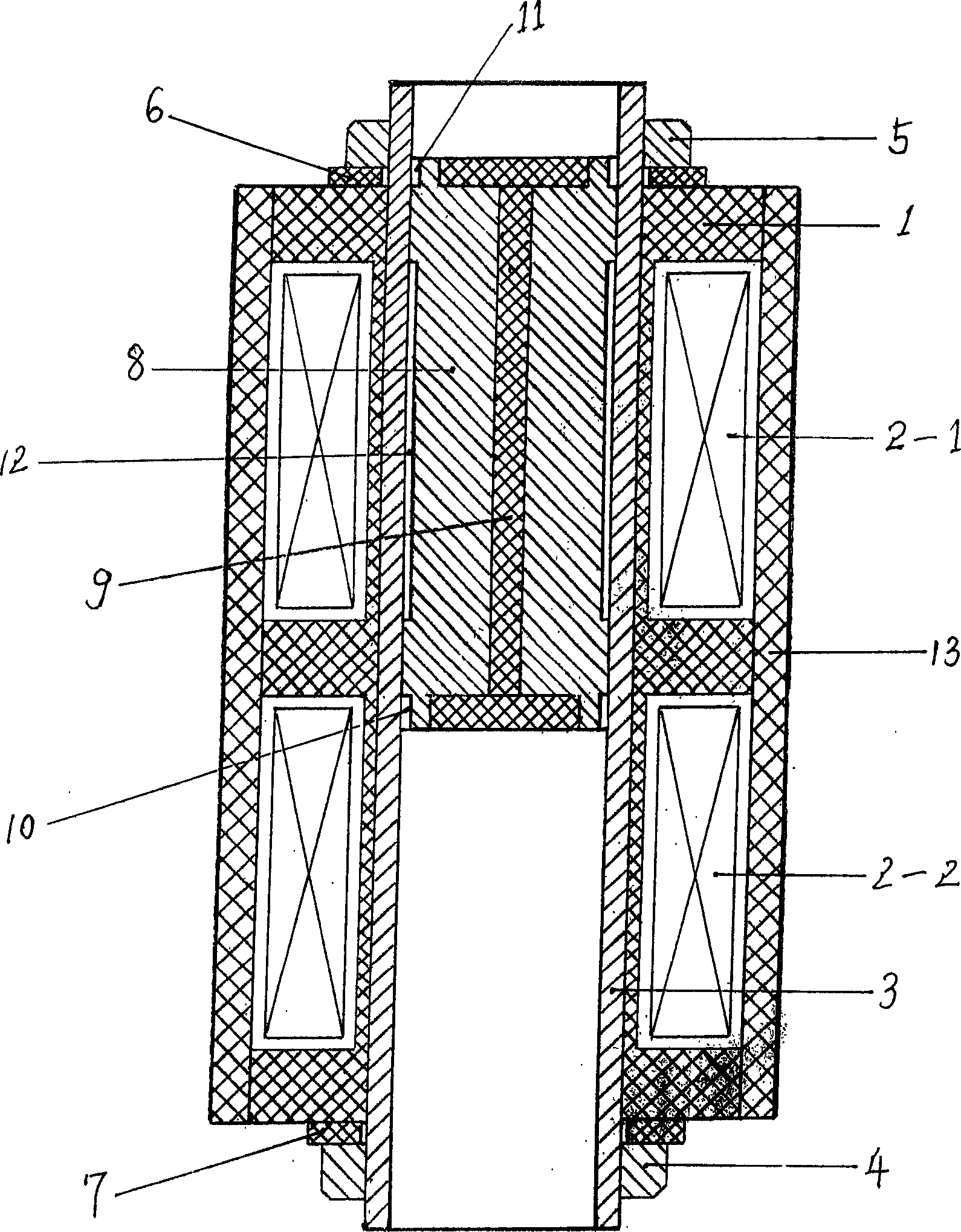

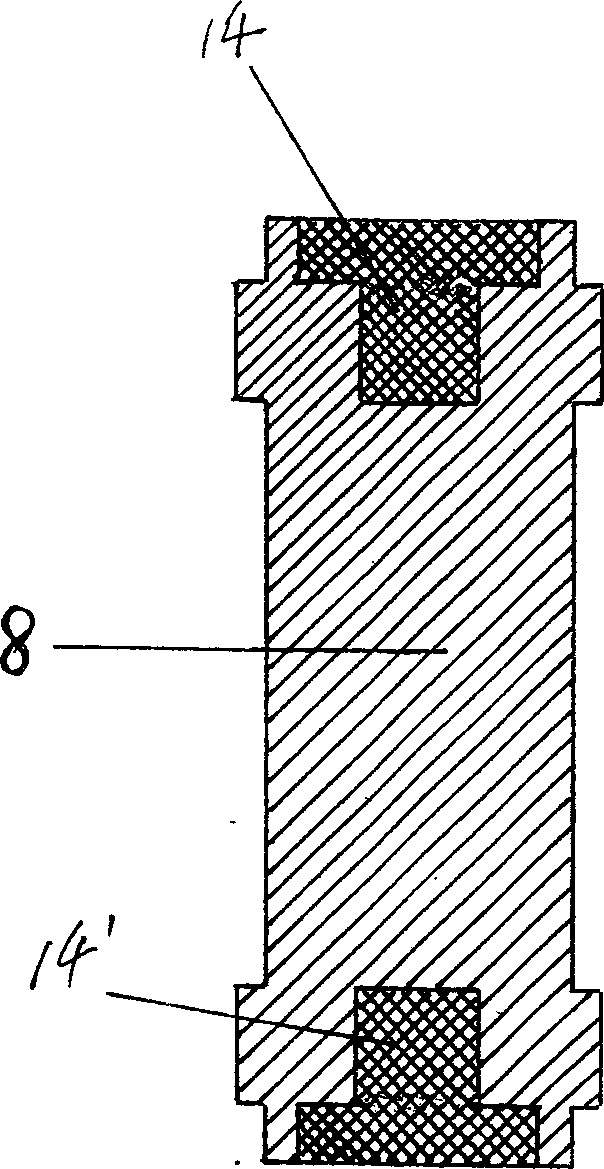

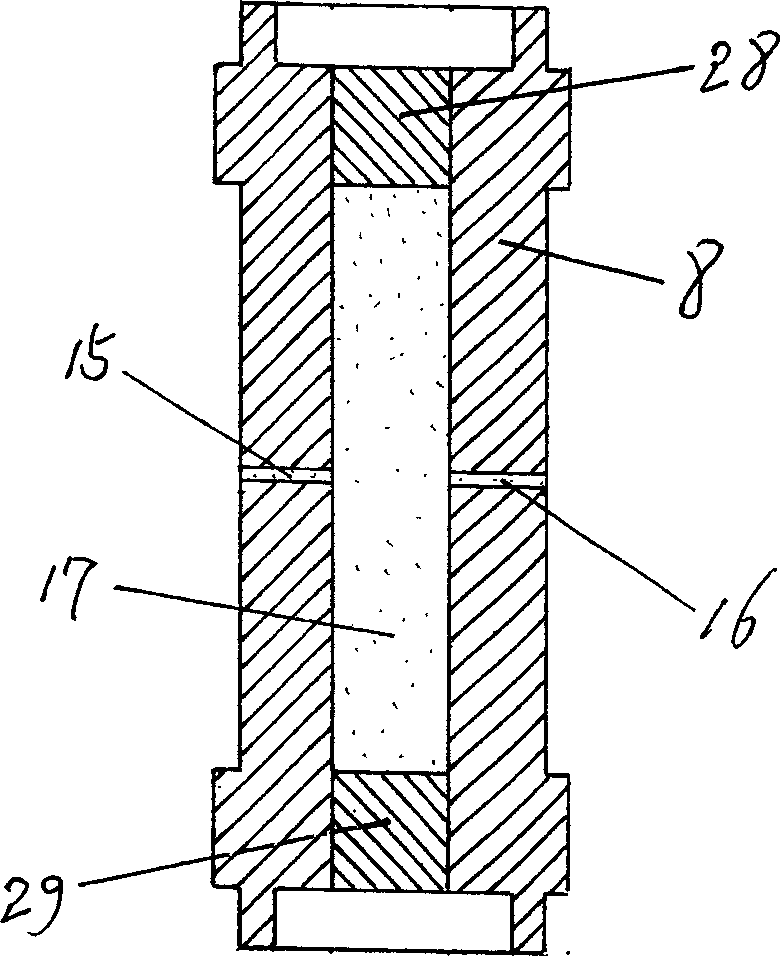

[0033] according to figure 1 As shown, the reluctance linear oscillating motor of the present invention is that two excitation coils 2-1 and 2-2 are coaxially arranged, and their skeletons are made of polyimide engineering plastics into an independent whole as a motor. Cylinder 1. A cylinder liner 3 made of ordinary brass is also installed in the cylinder body 1. After its outer circular side is processed into a threaded surface and coated with silicone grease, the brass nuts 4 and 5 at both ends and the silicone rubber gasket 6 and 7, fix it at the center of the motor, and then place a cylindrical mover core 8 with an overall size not less than the length of an excitation coil in the cylinder liner 3, the cylindrical mover core 8 is made of silicon steel, and The surface of the running-in part at both ends is hardened by chrome plating. In order to reduce the inertia of the cylindrical mover core 8 and improve its dynamic response speed, the cylindrical mover core 8 is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com